Coating material for paper product

A technology for coating materials and paper products, applied in paper coating, coating, papermaking, etc., can solve the problems of soybean protein adhesives such as poor water resistance, unsatisfactory water resistance, and affecting product quality, so as to achieve good plasticity and prevent precipitation , Increase the effect of cohesion and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

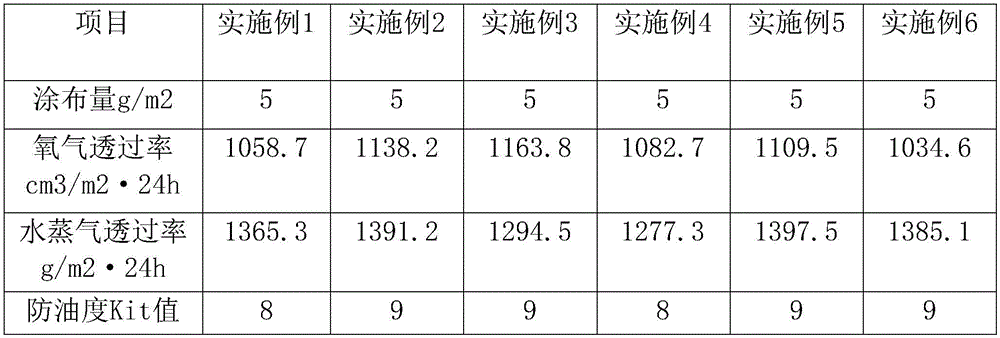

Examples

preparation example Construction

[0034] The preparation method of modified polylactic acid is as follows:

[0035] Weigh 5g of polylactic acid particles and dissolve them in 100mL of acetonitrile to obtain a solution with a concentration of 0.05g / mL, add 2.5g of PVP, shake well and let stand until the polylactic acid solid dissolves, then add 0.25g of montmorillonite, and disperse ultrasonically at 30°C 30min to obtain the oil phase mixture; take 50mL of 0.01g / mL polyvinyl alcohol aqueous solution, add 0.1g monoglyceride laurate, stir and dissolve to obtain the water phase mixture; stir the water phase mixture on a magnetic stirrer, and use a syringe to Add the oil phase mixture dropwise. After the dropwise addition, continue to stir until the organic solvent is completely volatilized. Centrifuge the obtained mixture containing polylactic acid particles for 20 minutes at a speed of 10000r / min. Pour off the supernatant and remove the solid particles in the lower layer Take it out and place it in a drying dish,...

Embodiment 1

[0037] Modified polylactic acid: 30 parts

[0038] Palygorskite: 15 parts

[0039] Adhesive A: 5 parts

[0040] Polyether-modified polydimethylsiloxane: 0.05 parts

[0041] Alkyl glucoside: 0.5 parts

[0042] Polyoxyethylene polyoxypropanolamine ether: 0.1 parts

[0043] Garlic oil: 0.5 parts

Embodiment 2

[0045] Modified polylactic acid: 50 parts

[0046] Palygorskite: 20 parts

[0047] Adhesive A: 15 parts

[0048] Polyether-modified polydimethylsiloxane: 2 parts

[0049] Alkyl glucoside: 0.8 parts

[0050] Polyoxyethylene polyoxypropanolamine ether: 0.6 parts

[0051] Garlic oil: 0.8 parts

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com