Preparation method and application of DTPA (diethylenetriaminepentaacetic acid)-modified magnetic graphene oxide composite

A technology of diethylenetriaminepentaacetic acid and composite materials, which is applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc. Removal effect, preparation process and simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

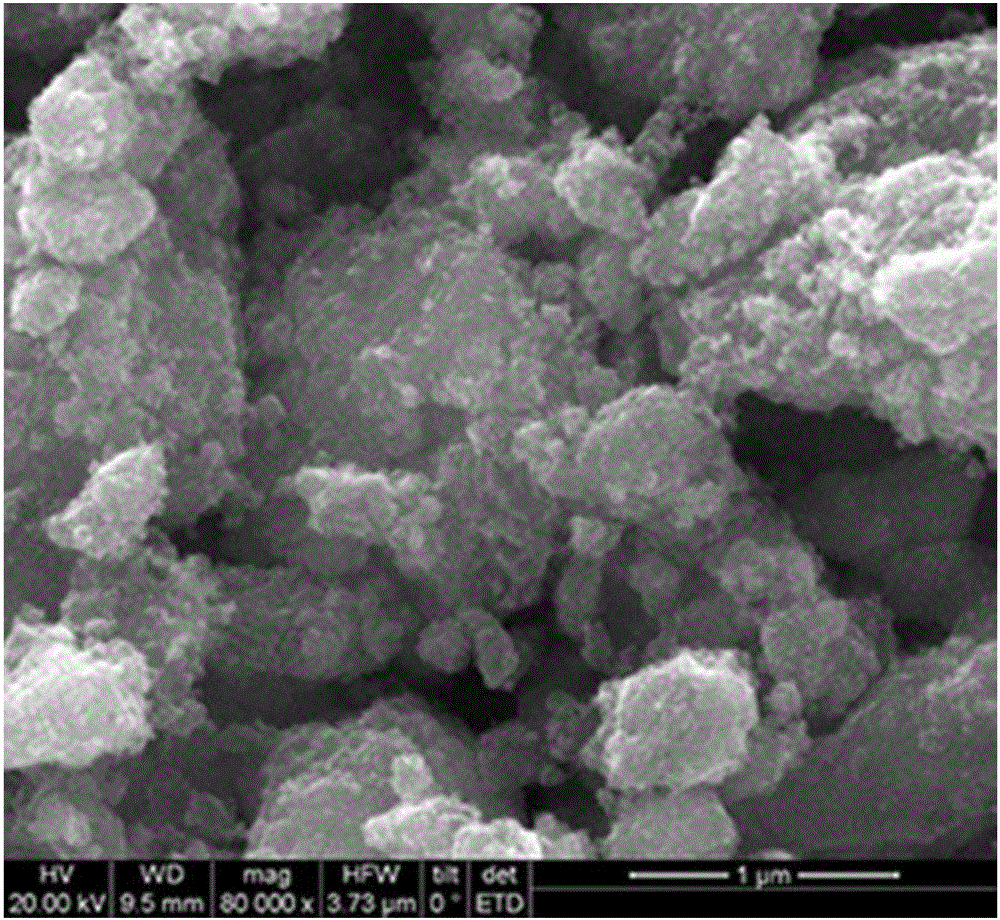

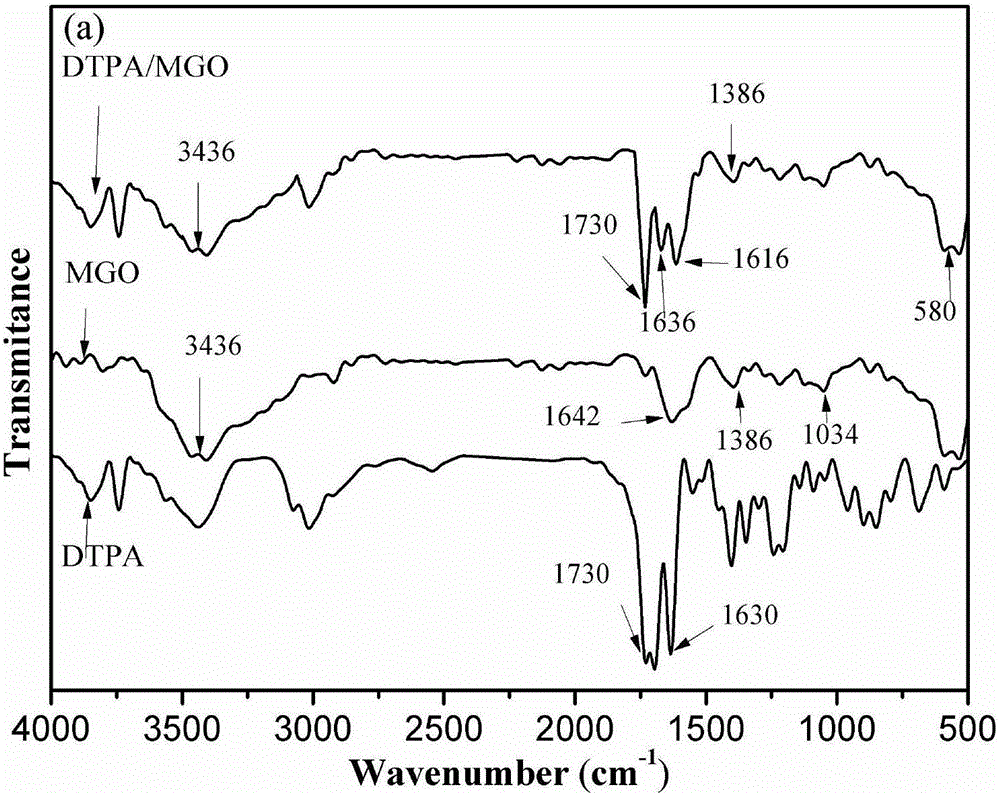

[0029] A kind of preparation of diethylenetriaminepentaacetic acid-supported graphene oxide composite material of the present invention adopts natural graphite powder as matrix material, and concrete preparation method is as follows:

[0030] First, 6g of natural graphite powder was added to 24mL of concentrated sulfuric acid, and 5g of phosphorus pentoxide and 5g of potassium persulfate were added under stirring conditions. Then heat the reaction in a water bath at 80°C for 6h, wash the obtained product with deionized water until neutral, and dry it in vacuum at 60°C for 24h to obtain pre-oxidized graphite; then add 6g of pre-oxidized graphite to 240mL 98%H 2 SO 4 solution (ice bath 0°C). Add 5g NaNO while stirring 3 , slowly add 30g KMnO three times 4 (keep the temperature below 20°C in an ice bath) to react for 4h. Then the temperature was raised to 35°C and stirred for 2 hours, 500 mL of deionized water was added to the system, the temperature was raised to 98°C for 1 ...

Embodiment 2

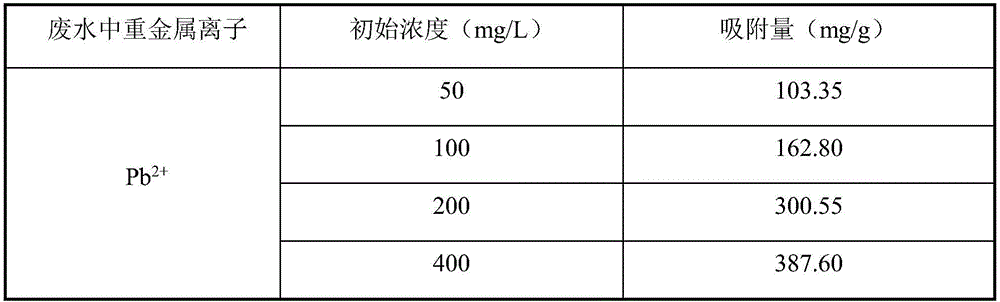

[0032] Diethylene triamine pentaacetic acid negatively modified magnetic graphene oxide composite material of the present invention treats Pb in wastewater 2+ , including the following steps:

[0033] Take 25mL of Pb with an initial concentration of 100-400mg / L 2+ Solution, add the diethylenetriaminepentaacetic acid negatively modified magnetic graphene oxide composite material that embodiment 1 makes, the consumption of this adsorbent is 10mg, carry out adsorption reaction in 25 ℃ constant temperature water-bath shaking table after 24 hours, pass through magnet The composite material is separated from the waste water, and the waste water is filtered with a 0.22um filter membrane, and the Pb in the waste water is determined by atomic absorption 2+ The content of the calculated adsorption capacity is shown in Table 1:

[0034] Table 1: Different Pb2+ The adsorption capacity of composite materials under the condition of initial concentration

[0035]

[0036] It can be see...

Embodiment 3

[0038] Diethylenetriaminepentaacetic acid negatively modified magnetic graphene oxide composite material of the present invention treats Pb in wastewater at different pH values 2+ , including the following steps:

[0039] Prepare six 25mL Pb with an initial concentration of 100mg / L 2+ solution, add 10 mg of the composite material prepared in Example 1, adjust the pH value of the solution to 1.0, 2.0, 3.0, 4.0, 5.0, and 6.0 with HCl and NaOH, and carry out the adsorption reaction in a constant temperature water bath shaker at 25°C for 24 hours , the composite material is separated from the waste water by a magnet, the waste water is filtered with a 0.22um filter membrane, and the Pb in the waste water is determined by atomic absorption 2+ The content of , the calculated degradation results are shown in Table 2:

[0040] Table 2: Pb at different solution pH values 2+ The adsorption data

[0041] pH

[0042] It can be seen from Table 2 that when the initial pH of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com