Nitrogen functional carbon material loaded with transition metal chalcogenide as well as preparation and application of nitrogen functional carbon material

A technology of transition metal chalcogenides and chalcogenides, applied in chemical instruments and methods, physical/chemical process catalysts, electrolysis processes, etc., can solve the problems of hydrogen production efficiency gap and achieve high efficiency and excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

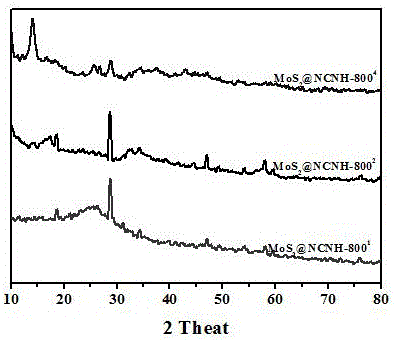

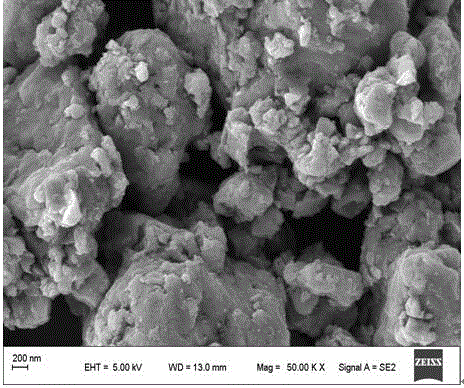

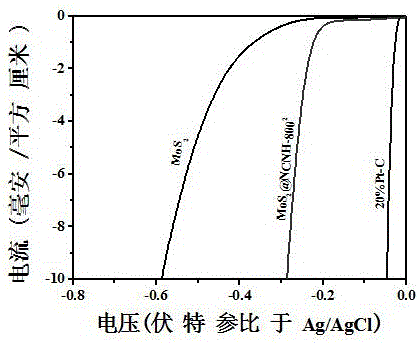

[0029] Example 1. Nitrogen-functionalized carbon material MoS 2 @NCNH-800 2 preparation of

[0030] (1) Preparation of nitrogen-doped zeolite imidazolate framework material: disperse 4g of 2-methylimidazole in 46mL of ammonia solution as solution A; disperse 4g of zinc acetate dihydrate in 26mL of deionized water as solution B, After mixing the above two solutions, stir at room temperature for 3 hours, collect the product by filtration, wash the product with deionized water until neutral, soak it in chloroform overnight, collect it by centrifugation, and dry it in vacuum at 100°C overnight to obtain nitrogen-doped zeolite imidazole Ester skeleton structure material.

[0031](2) Preparation of nitrogen-functionalized carbon material: Weigh 4g of zinc chloride and dissolve it completely in 25mL of ethanol, then disperse the nitrogen-doped zeolite imidazolate framework material prepared above in it, and stir in an oil bath at 80°C Until evaporated to dryness, under the protect...

Embodiment 2

[0034] Example 2. Nitrogen-functionalized carbon material CoSe 2 @NCNH-800 2 preparation of

[0035] (1) Preparation of nitrogen-doped zeolite imidazolate framework material: same as Example 1;

[0036] (2) Preparation of nitrogen functionalized carbon material: same as Example 1;

[0037] (3) Nitrogen-functionalized carbon material CoSe 2 @NCNH-800 2 Preparation of nitrogen-functionalized carbon material: Disperse 170 mg of nitrogen-functionalized carbon material in 180 mL of absolute ethanol, and stir for 10 to 60 minutes to obtain a suspension; add 51 mg of cobalt chloride, 88 mg of selenium dioxide, and 2.1 g of sodium acetate to the above suspension, Stir for 12-24 hours under gas protection; ultrasonically disperse sodium borohydride in absolute ethanol, add sodium borohydride ethanol solution dropwise to the above solution, stir for 1-24 hours, collect the product by centrifugation, and wash with absolute ethanol Multiple times, dry at 60°C for 24~64 hours. Grind ...

Embodiment 3

[0039] Example 3. Nitrogen functionalized carbon material CoS 2 @NCNH-800 2 preparation of

[0040] (1) Preparation of nitrogen-doped zeolite imidazolate framework material: same as Example 1;

[0041] (2) Preparation of nitrogen functionalized carbon material: same as Example 1;

[0042] (3) Nitrogen-functionalized carbon material CoS 2 @NCNH-800 2 Preparation: Disperse 700mg of cobalt chloride and 1.5g of thiourea in 80mL of deionized water to obtain a clear solution, then disperse 50mg of nitrogen-functionalized carbon material in the above solution, and ultrasonicate for 1h; then place it in an autoclave, Hydrothermal reaction at 220°C for 24 hours, naturally cooled to room temperature, washed with deionized water several times, dried to obtain a black powder, and ground to obtain a catalyst, which is recorded as CoS 2 @NCNH-800 2 .

[0043] (4) CoS 2 @NCNH-800 2 Catalytic efficiency and effect: test method and condition are with embodiment 1. Test results: The c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Onset potential | aaaaa | aaaaa |

| Overpotential | aaaaa | aaaaa |

| Electric potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com