Method for preparing nano-silicon dioxide by utilizing rice hull ash

A nano-silica, rice husk ash technology, applied in the directions of silica, silica, chemical instruments and methods, can solve problems such as environmental pollution, and achieve shortened reaction time, simple equipment manufacturing process, and small particle size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A kind of method utilizing rice husk ash to prepare nano silicon dioxide, concrete method steps are as follows:

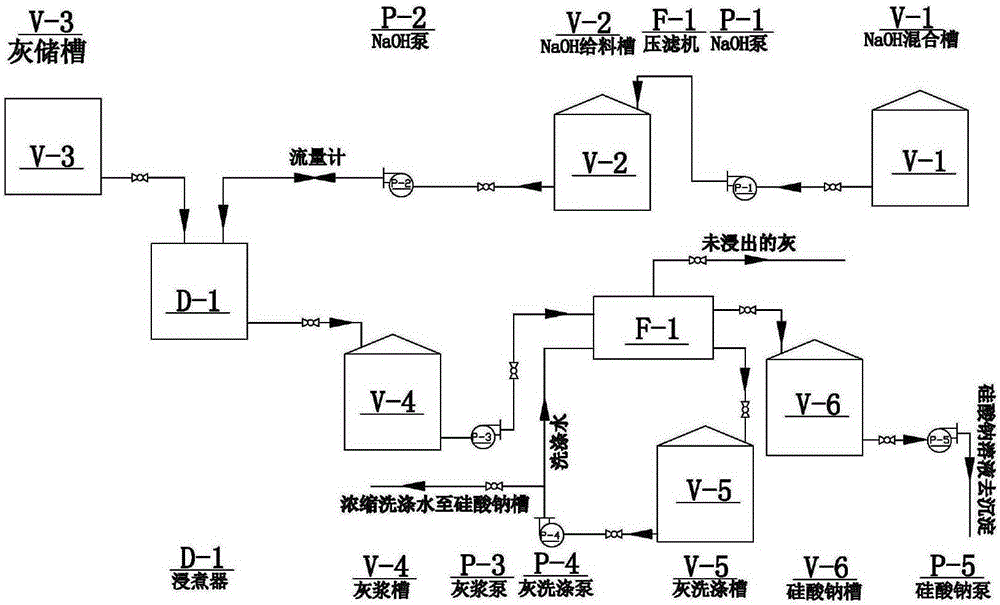

[0045] (1) Preparation of sodium silicate:

[0046] Mix rice husk ash and alkali solution evenly according to the mass ratio of 1:20, put them in a digester, heat up the digester to 85-℃, stop heating after 1.5 hours of reaction, cool to room temperature, and transfer to the mortar tank , and then filter and precipitate through a filter press to obtain a sodium silicate solution, and the Baume degree of the sodium silicate solution is 45 degrees;

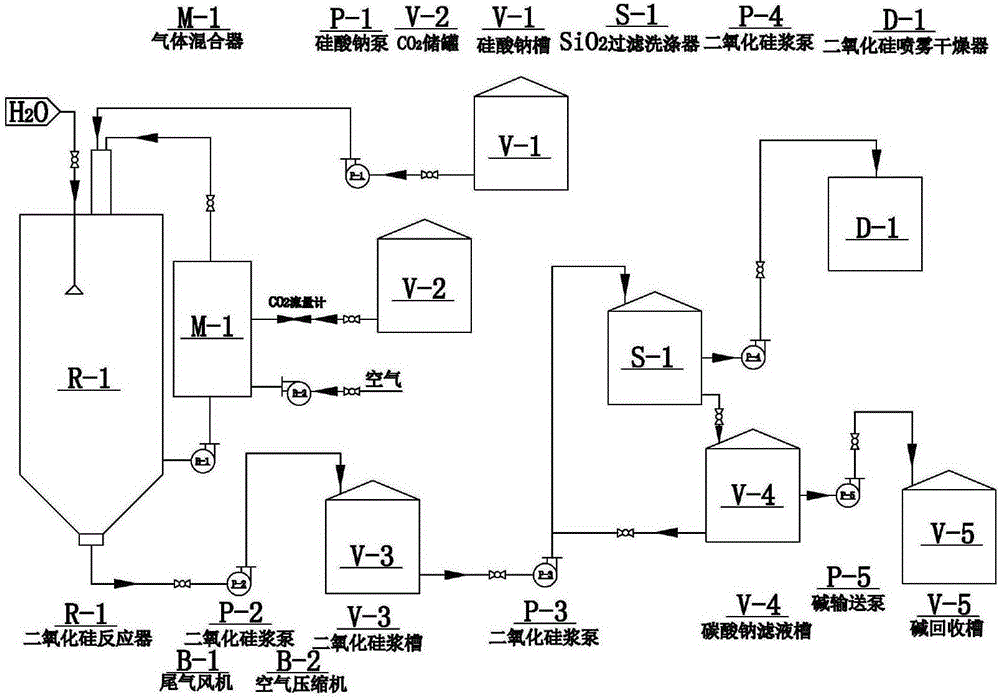

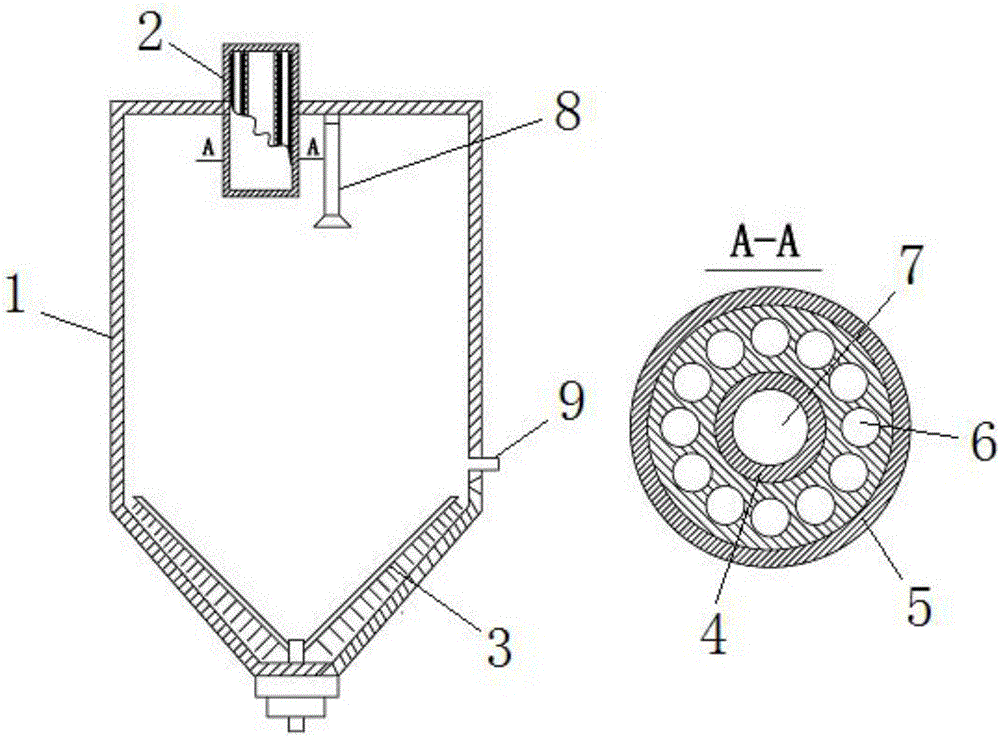

[0047] (2) Preparation of nano silicon dioxide:

[0048] The sodium silicate solution described in step (1) is warmed up to 70° C., pumped into the spray gun of the spray drying tower, and simultaneously fed into CO and air mixed gas, the CO 2 The pressure of mixed gas with air: 1.8MPa, temperature: 80°C, flow rate: 1L / min, the mass volume ratio of the sodium silicate solution to the mixed gas is 1g:2L; the reac...

Embodiment 2

[0057] A kind of method utilizing rice husk ash to prepare nano silicon dioxide, concrete method steps are as follows:

[0058] (1) Preparation of sodium silicate:

[0059] Mix rice husk ash and alkali solution evenly according to the mass ratio of 1:30, place in a digester, heat up the digester to 120°C, stop heating after reacting for 5 hours, cool to room temperature, transfer to the mortar tank, Then filter and precipitate through a filter press to obtain a sodium silicate solution, and the Baume degree of the sodium silicate solution is 45 degrees;

[0060] (2) Preparation of nano silicon dioxide:

[0061] The sodium silicate solution described in step (1) is warmed up to 90°C, pumped into the spray gun of the spray drying tower, and simultaneously fed into CO2 and air mixed gas, the CO 2 The pressure of mixed gas with air: 3.0MPa, temperature: 100°C, flow rate: 15L / min, the mass volume ratio of the sodium silicate solution to the mixed gas is 1g:8L; the reacted slurry ...

Embodiment 3

[0070] A kind of method utilizing rice husk ash to prepare nano silicon dioxide, concrete method steps are as follows:

[0071] (1) Preparation of sodium silicate:

[0072] Mix the rice husk ash and alkali solution evenly according to the mass ratio of 1:18, put them in a digester, heat up the digester to 110°C, stop heating after reacting for 3.5 hours, cool to room temperature, and transfer to the mortar tank. Then filter and precipitate through a filter press to obtain a sodium silicate solution, and the Baume degree of the sodium silicate solution is 45 degrees;

[0073] (2) Preparation of nano silicon dioxide:

[0074] The sodium silicate solution described in step (1) is warmed up to 85° C., pumped into the spray gun of the spray drying tower, and simultaneously fed into CO and air mixed gas, the CO 2 The pressure of mixed gas with air: 2.5MPa, temperature: 95°C, flow rate: 12L / min, the mass volume ratio of the sodium silicate solution to the mixed gas is 1g: 6.5L; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com