High-dielectric-constant micro-filtration and ultra-filtration membrane and preparation method thereof

A high dielectric constant, ultrafiltration membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of separation performance degradation, reduced membrane service life, and restrictions on the application of water treatment, to achieve The modification method is simple, prolongs the service life, improves the flux and the effect of the produced water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A high dielectric constant micro-ultrafiltration membrane, which contains calcium copper titanate and polyvinylidene fluoride.

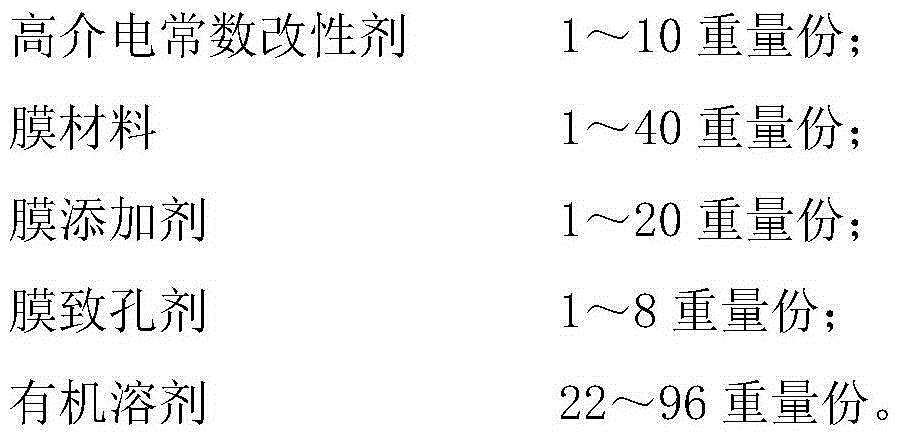

[0035] The composition and the weight and number ratio of the raw material of the micro-ultrafiltration membrane are:

[0036]

[0037]

[0038] A high dielectric constant micro-ultrafiltration membrane, the preparation method of which is:

[0039] 1) Modifier preparation: vacuum-dry copper calcium titanate at 150° C. for 24 hours, and collect the dried copper calcium titanate.

[0040] 2) Preparation of casting solution: Take 0.1Kg of calcium copper titanate, dissolve it in 7.8Kg of N-methylpyrrolidone, oscillate for 5 hours with ultrasonic waves, and then heat and stir for 6 hours until it is completely dissolved. Then add 1.8Kg of polyvinylidene fluoride, 0.3Kg of organosilane, and 0.8Kg of polyvinylpyrrolidone 90 in sequence, heat and stir at 60°C for 24 hours, and let it stand for defoaming to obtain a homogeneous casting solution;...

Embodiment 2

[0045] A high dielectric constant micro-ultrafiltration membrane, which contains calcium copper titanate and polyvinylidene fluoride.

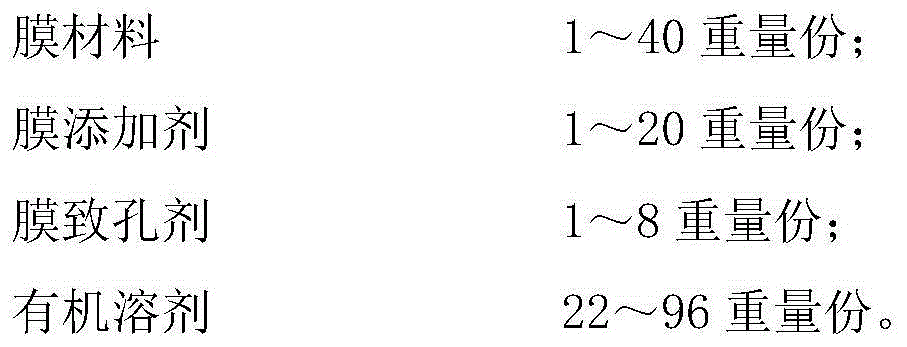

[0046] The composition and the weight and number ratio of the raw material of the micro-ultrafiltration membrane are:

[0047]

[0048] A high dielectric constant micro-ultrafiltration membrane, the preparation method of which is:

[0049] 1) Modifier preparation: vacuum-dry copper calcium titanate at 150° C. for 24 hours, and collect the dried copper calcium titanate.

[0050] 2) Preparation of casting solution: Take 0.15Kg of calcium copper titanate, dissolve it in 6.95Kg of N-methylpyrrolidone, oscillate for 5 hours with ultrasonic waves, and then heat and stir for 6 hours until it is completely dissolved. Then add 1.8Kg of polyvinylidene fluoride, 0.6Kg of organosilane, and 0.5Kg of polyvinylpyrrolidone 90 in sequence, heat and stir at 60°C for 24 hours, and let it stand for defoaming to obtain a homogeneous casting solution;

[0051]...

Embodiment 3

[0055] A high dielectric constant micro-ultrafiltration membrane, which contains calcium copper titanate and polyvinylidene fluoride.

[0056] The composition and the weight and number ratio of the raw material of the micro-ultrafiltration membrane are:

[0057]

[0058] A high dielectric constant micro-ultrafiltration membrane, the preparation method of which is:

[0059] 1) Modifier preparation: vacuum-dry copper calcium titanate at 150° C. for 24 hours, and collect the dried copper calcium titanate.

[0060] 2) Preparation of casting solution: Take 0.1Kg of calcium copper titanate, dissolve it in 6.4Kg of N-methylpyrrolidone, oscillate for 5 hours with ultrasonic waves, and then heat and stir for 6 hours until it is completely dissolved. Add 1.8Kg of polyvinylidene fluoride, 0.8Kg of organosilane, and 0.8Kg of polyvinylpyrrolidone 90 in sequence, heat and stir at 60°C for 24 hours, and let it stand for defoaming to obtain a homogeneous casting solution;

[0061] 3) Fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com