High-specific-surface-area nitrogen doped grapheme and preparation method thereof

A nitrogen-doped graphene, large specific surface area technology, applied in graphene, chemical instruments and methods, inorganic chemistry and other directions, to achieve the effect of time and energy cost reduction, high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

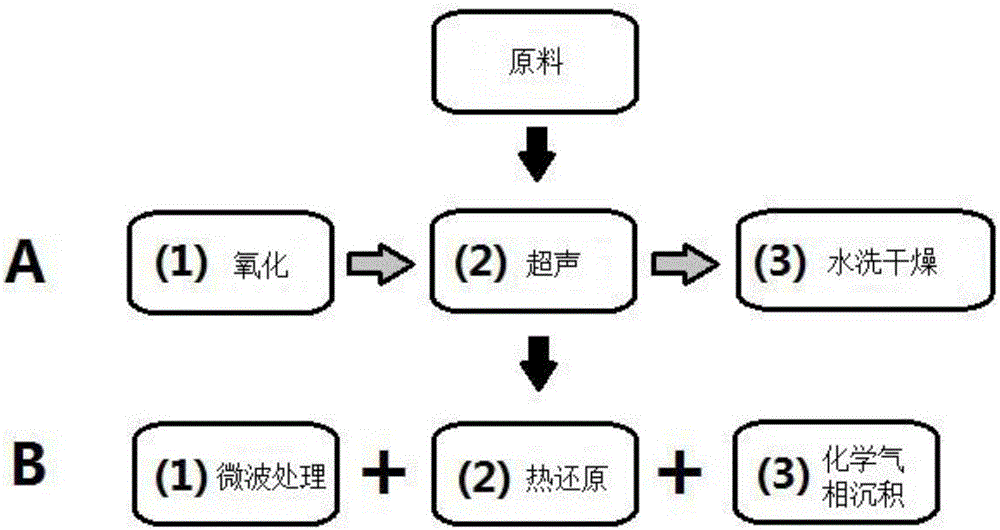

Method used

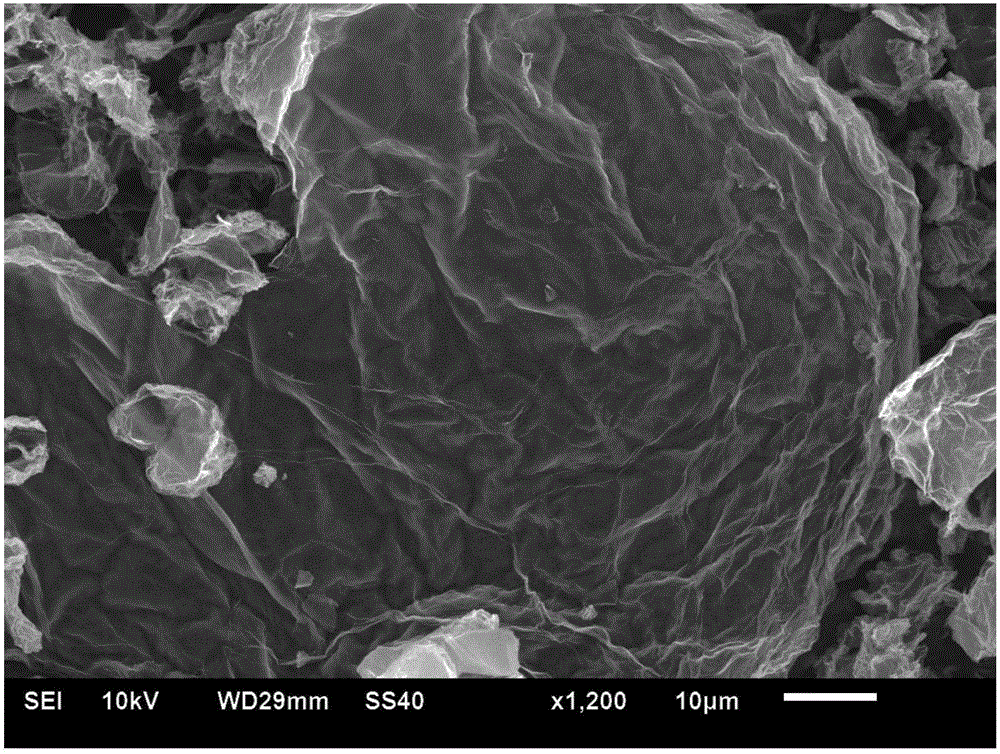

Image

Examples

Embodiment 1

[0036] A.Hummers method prepares graphene oxide:

[0037] (1) Oxidation: take by weighing natural flake graphite 3g, potassium permanganate 7g, wherein the diameter of natural flake graphite particle is 1-200 micron, slowly add 60ml mass concentration after two kinds of raw materials are mixed and be the vitriol oil of 98%, concentrated The sulfuric acid temperature is 2°C. After the mixture was kept at 0-2°C and stirred for 60 minutes, the temperature was adjusted to 30°C, and then kept stirring for 60 minutes. Slowly add 150ml of deionized water at a temperature of 2°C for the first time, while increasing the stirring speed. Raise the temperature to 95°C, keep warm for 15 minutes, then add 6ml of hydrogen peroxide with a mass fraction of 30%, and then add 250ml of deionized water for dilution. The concentration of graphite oxide is about 6mg / ml to obtain a graphite oxide dilution.

[0038] (2) Ultrasonic: The obtained graphite oxide solution is subjected to ultrasonic trea...

Embodiment 2

[0046] A.Hummers method prepares graphene oxide:

[0047] (1) Oxidation: take artificial graphite powder 3.5g, potassium permanganate 6.5g, wherein the diameter of artificial graphite powder particle is 1-200 micron, after two kinds of raw materials mix, slowly add 105ml concentration and be the concentrated sulfuric acid of 98%, The temperature of concentrated sulfuric acid is 2°C. After the mixture was kept at 0-2°C and stirred for 120 minutes, the temperature was adjusted to 40°C, and then kept stirring for 120 minutes. Slowly add 230ml of deionized water at a temperature of 2°C for the first time, while increasing the stirring speed. Raise the temperature to 90°C, keep warm and heat for 15 minutes, then add 11ml of hydrogen peroxide with a mass fraction of 30%, and then add 200ml of deionized water to dilute the acid solution. The graphite oxide concentration is about 10mg / ml to obtain a graphite oxide dilution.

[0048] (2) Ultrasonic: Ultrasonic treatment is performed ...

Embodiment 3

[0056] A.Hummers method prepares graphene oxide:

[0057] (1) Oxidation: take expanded graphite 10g, potassium permanganate 20g, wherein the diameter of expanded graphite particle is 1-200 micron, slowly add 250ml concentration after two kinds of raw materials mix and be the vitriol oil of 98%, the vitriol oil temperature is 2°C. After the mixture was kept at 0-2°C and stirred for 90 minutes, the temperature was adjusted to 35°C, and then kept stirring for 90 minutes. Slowly add 500ml of deionized water at a temperature of 2°C for the first time, while increasing the stirring speed. Raise the temperature to 93°C, keep warm for 10 minutes, then add 25ml of hydrogen peroxide with a mass fraction of 30%, and then add 700ml of deionized water to dilute the acid solution. The graphite oxide concentration is about 8mg / ml to obtain a graphite oxide dilution.

[0058] (2) Ultrasound: The obtained graphite oxide solution was subjected to ultrasonic treatment, the power of the ultraso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com