Method for degrading high-molecular-weight polysaccharide containing alpha-1, 3-glycosidic bonds

A technology of large molecular weight and glycosidic bonds, which is applied in the field of degrading large molecular weight polysaccharides containing α-1,3-glycosidic bonds, can solve the problems of unsuitability for industrialized production expansion, product structure and activity destructiveness, and low degradation rate. Reduce platelet adhesion rate and blood viscosity, improve immune function, and have good effects on hypercholesterolemia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

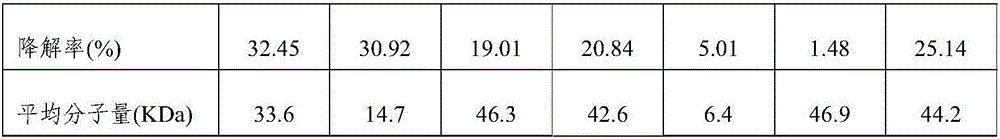

Embodiment 1

[0031] A kind of method that adopts electric Fenton method to degrade tremella polysaccharide: take by weighing 3000g tremella polysaccharide (molecular weight 560KDa), be dispersed in 3.0Kg dehydrated alcohol, join in 15L distilled water, make the sugar solution that concentration is 200mg / ml, pack into In an electrolytic cell with a volume of 24L, weigh 149.1g of sodium sulfate and dissolve it in the polysaccharide solution, adjust the pH to 3 with 1mol / L hydrochloric acid, use a 30cm×30cm wire mesh as the anode, and a 30cm×30cm porous graphite as the cathode, and the distance between the two electrodes is 5cm, connected to 12V DC, the current density is 12mA / cm 2, and use the aeration device to feed in purified air at a speed of 1.74L / min (or to feed in oxygen at a speed of 0.58L / min, the aeration device contains three air holes, and the three air holes are blown into oxygen at the same time), per liter The amount of air introduced into the Tremella polysaccharide solution ...

Embodiment 2

[0033] A kind of method that adopts electric Fenton method to degrade tremella polysaccharide: take by weighing 900g tremella polysaccharide (molecular weight 400KDa), be dispersed in 3.0Kg dehydrated alcohol, join in 15L distilled water, make the sugar solution that concentration is 60mg / ml, pack In an electrolytic cell with a volume of 24L, weigh 106.5g of sodium sulfate and dissolve it in the polysaccharide solution, adjust the pH to 3 with 1mol / L hydrochloric acid, use a 30cm×30cm wire mesh as the anode, and a 30cm×30cm porous graphite as the cathode, and the distance between the two electrodes is 8cm, connected to 10V DC, the current density is 10mA / cm 2 , and feed oxygen at a speed of 0.6L / min (the aeration device contains two vent holes, and the two vent holes are blown into oxygen at the same time), the amount of air per liter of tremella polysaccharide solution is about 4.0L, and the agitator Stir at 250rpm, electrolyze for 50 minutes at room temperature, stop power s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com