Modified ethylene propylene diene monomer composite cable material resistant to high and low temperatures

A technology of EPDM rubber and composite cables, which is applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems of high and low temperature resistance, strength and aging resistance, etc., to improve physical properties, Effect of improving reinforcement, improving electrical insulation and oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

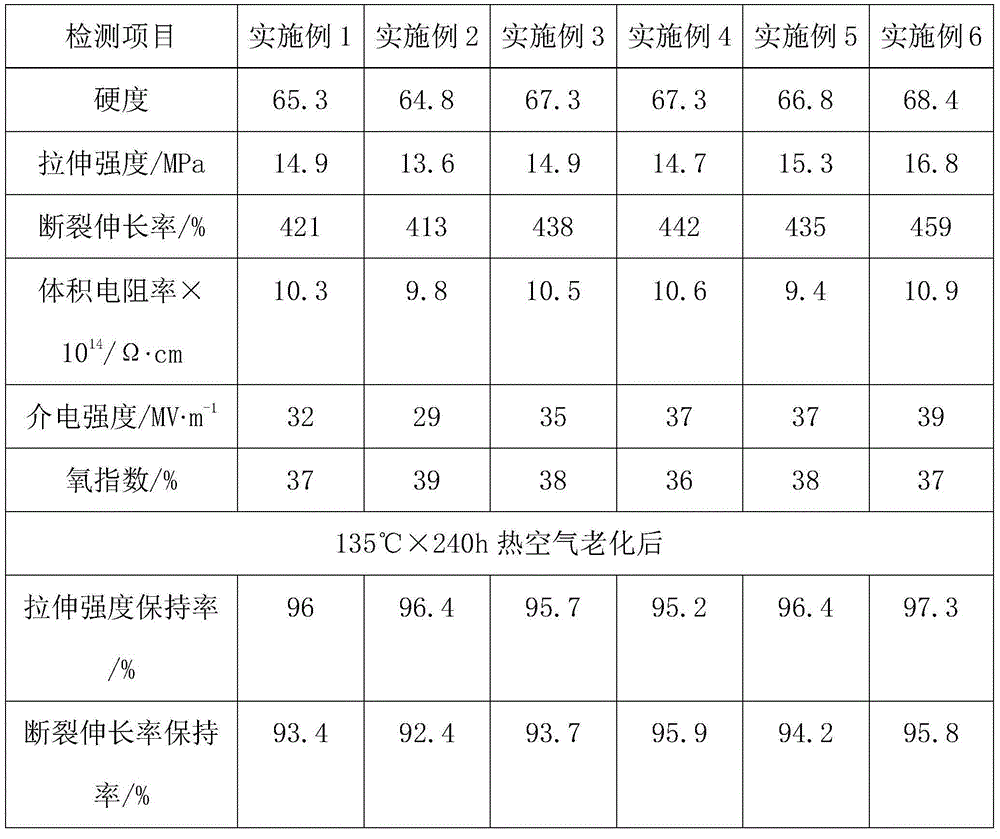

Examples

Embodiment 1

[0018]A high and low temperature resistant modified EPDM composite cable material proposed by the present invention, its raw materials include the following components by weight: 40 parts of maleic anhydride grafted EPDM rubber, methyl vinyl phenyl silicon 60 parts of rubber, 10 parts of ethylene-octene copolymer, 5 parts of white carbon black, 35 parts of mica, 20 parts of calcined clay, 50 parts of hydrotalcite, 2 parts of stearic acid, 6 parts of zinc oxide, 0.8 parts of sulfur, peroxide 1.7 parts of bis(2,4-dichlorobenzoyl), 0.5 parts of ethylene glycol, 2.5 parts of polyethylene glycol, 0.8 parts of 3-aminopropyltrimethoxysilane, 3 parts of accelerator, 3 parts of plasticizer , 1 part of anti-aging agent.

Embodiment 2

[0020] A high and low temperature resistant modified EPDM composite cable material proposed by the present invention, its raw materials include the following components by weight: 60 parts of maleic anhydride grafted EPDM rubber, methyl vinyl phenyl silicon 40 parts of rubber, 3 parts of ethylene-octene copolymer, 20 parts of white carbon black, 10 parts of mica, 50 parts of calcined clay, 30 parts of hydrotalcite, 5 parts of stearic acid, 3 parts of zinc oxide, 2 parts of sulfur, peroxide 1 part of bis(2,4-dichlorobenzoyl), 2 parts of ethylene glycol, 1 part of polyethylene glycol, 2 parts of 3-aminopropyltrimethoxysilane, 1 part of accelerator, 7 parts of plasticizer , 3.8 parts of anti-aging agent; wherein, the plasticizer is prepared according to the following process: add 0.01 part of lead oxide to 30 parts of glycerin by weight and stir evenly, add 20 parts of soybean oil, stir and heat up to 225 ° C and react for 3 hours , and then placed in ice water to cool to obtain ...

Embodiment 3

[0022] A high and low temperature resistant modified EPDM composite cable material proposed by the present invention, its raw materials include the following components by weight: 58 parts of maleic anhydride grafted EPDM rubber, methyl vinyl phenyl silicon 52 parts of rubber, 7.5 parts of ethylene-octene copolymer, 13 parts of white carbon black, 29.3 parts of mica, 36 parts of calcined clay, 45.6 parts of hydrotalcite, 3.8 parts of stearic acid, 5.2 parts of zinc oxide, 1.6 parts of sulfur, peroxide 1.46 parts of bis(2,4-dichlorobenzoyl), 1.9 parts of ethylene glycol, 2.34 parts of polyethylene glycol, 1.6 parts of 3-aminopropyltrimethoxysilane, 2 parts of accelerator, 5.9 parts of plasticizer , 3.5 parts of anti-aging agent; wherein, the plasticizer is prepared according to the following process: add 0.005 parts of lead oxide to 50 parts of glycerin by weight and stir evenly, add 30 parts of soybean oil, stir and heat up to 200 ° C and then react 5.5 h, then placed in ice w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com