Transition metal-doped carbon fluorescent quantum dot preparation method

A carbon fluorescent quantum dot, transition metal technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems that have not been effectively solved, change the fluorescence emission characteristics, etc., and achieve low cost, simple operation method, and enhanced absorption intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Dissolve 50 micrograms of 1-(2-pyridylazo)-2-naphthol and 80 micrograms of manganese chloride hexahydrate in 10 milliliters of absolute ethanol, sonicate for 5 minutes, and add them to the polytetrafluoroethylene reactor for solvent Thermal reaction, the reaction temperature is 180°C, after 4 hours of reaction, cool down naturally, add 40 ml of pure water, and after the solid is precipitated, the liquid phase is obtained by centrifugation (12500g, 30 minutes), which is the aqueous dispersion of manganese-doped carbon dots. Concentrate to 15mL by rotary evaporation (70°C, 150g) (temperature, rotation speed), put it into a 3500kDa dialysis bag, dialyze in 500ml of pure water for 48 hours and then vacuum dry to obtain a solid product of manganese-doped carbon dots.

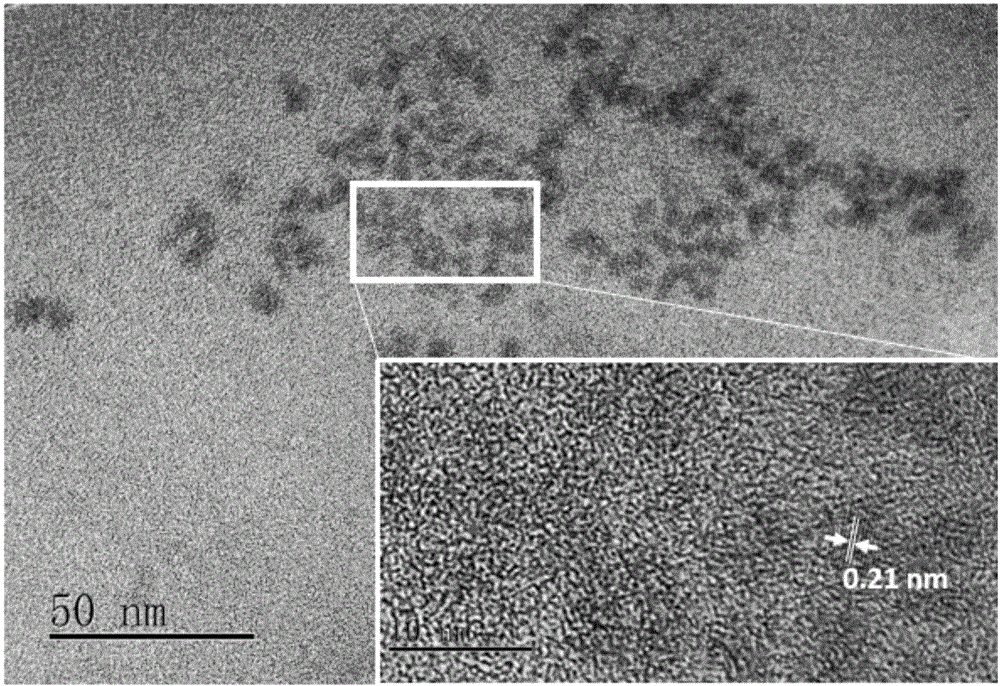

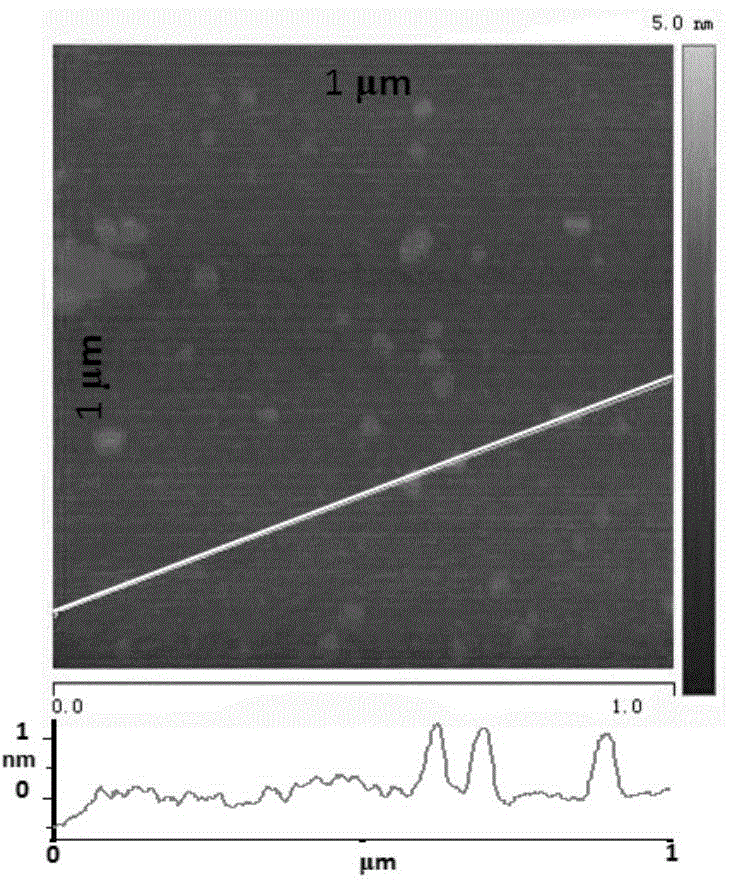

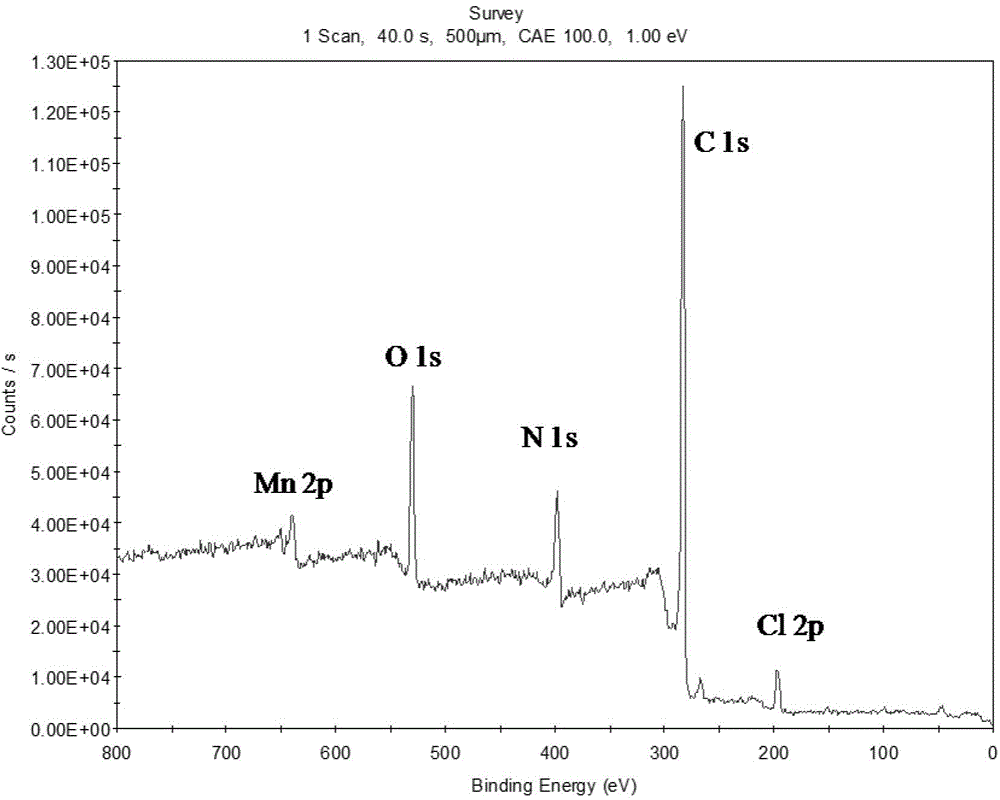

[0029] Through transmission electron microscopy and atomic force analysis (seefigure 1 , figure 2 ) shows that the manganese-doped carbon dots obtained in the experiment are mainly structures with an average ...

Embodiment 2

[0032] Dissolve 50 micrograms of alizarin complex indicator and 80 micrograms of zinc chloride hexahydrate in 10 mL of absolute ethanol, ultrasonicate at 5000 Hz for 20 minutes, and add them into a polytetrafluoroethylene reactor for solvothermal reaction at a temperature of 200 °C After reacting for 10 hours, cool naturally, add 40 ml of pure water, and centrifuge (12500g, 30 minutes) to obtain the liquid phase after the solid is precipitated. Concentrate to 15 mL, put it into a 3500 kDa dialysis bag, dialyze in 500 mL of pure water for 48 hours, and then vacuum dry to obtain a solid product of zinc-doped carbon dots.

Embodiment 3

[0034] Dissolve 50 micrograms of bromocresol violet and 80 micrograms of ferric chloride hexahydrate in 10 mL of absolute ethanol, ultrasonicate at 16000 Hz for 5 minutes, and add them into a polytetrafluoroethylene reactor for solvothermal reaction. The reaction temperature is 180 ° C. Cool naturally after 4 hours, add 40 ml of pure water, and centrifuge (12500g, 30 minutes) to obtain the liquid phase after the solid is precipitated, which is the water dispersion of iron-doped carbon dots. 15mL was put into a 3500kDa dialysis bag, dialyzed in 500ml of pure water for 48 hours and then vacuum-dried to obtain a solid product of iron-doped carbon dots.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mean scale | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com