Total mixed ration fodder for mutton sheep at fattening stage

A pre-mixed feed and full-mixed technology, which is applied to animal feed, animal feed, molding or processing of animal feed, etc., can solve the problems of not being able to meet the demand for effective fiber, adverse effects on animal health, and speed up the passage of feed, and achieve Improve the feeding method, improve the absorption and utilization rate of sheep, and reduce the cost of breeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A kind of total mixed ration feed for mutton sheep in the fattening stage, the total mixed ration feed is prepared according to the following method:

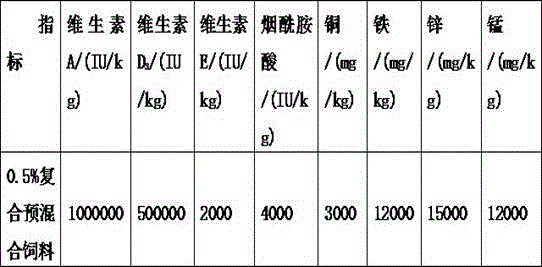

[0041]1) Take 15 parts by weight of alfalfa grass, 13 parts of corn, 3 parts of distiller's grains, 3 parts of soybean meal, 3 parts of malt root, 2 parts of corn fiber, 3 parts of cottonseed meal, 1 part of molasses, 0.5 parts of stone powder, calcium hydrogen phosphate 0.2 parts, 0.5 parts of bentonite, 0.3 parts of baking soda, 0.3 parts of sodium chloride, 0.1 parts of sodium sulfate, 0.2 parts of montmorillonite, 0.2 parts of ammonium chloride, 0.1 parts of monensin, 0.4 parts of 0.5% compound premixed feed ;

[0042] 2) Mix alfalfa grass, corn, distiller's grains, soybean meal, malt root, corn fiber, cottonseed meal and molasses, grind them, pass through a 40-mesh sieve, and obtain mixed powder A;

[0043] 3) Mix the mixed powder A obtained in step 2), and stone powder, calcium hydrogen phosphate, bentonite, bakin...

Embodiment 2

[0048] A kind of total mixed ration feed for mutton sheep in the fattening stage, the total mixed ration feed is prepared according to the following method:

[0049] 1) Take 60 parts of alfalfa, 40 parts of corn, 15 parts of distiller's grains, 15 parts of soybean meal, 16 parts of malt root, 16 parts of corn fiber, 14 parts of cotton meal, 2 parts of molasses, 1 part of stone powder, and calcium hydrogen phosphate in parts by weight 1 part, 2 parts of bentonite, 1 part of baking soda, 1.5 parts of sodium chloride, 1 part of sodium sulfate, 1 part of montmorillonite, 2 parts of ammonium chloride, 0.2 part of monensin, 0.8 part of 0.5% compound premixed feed ;

[0050] 2) Mix alfalfa grass, corn, distiller's grains, soybean meal, malt root, corn fiber, cottonseed meal and molasses, grind them, pass through a 40-mesh sieve, and obtain mixed powder A;

[0051] 3) Mix the mixed powder A obtained in step 2), and stone powder, calcium hydrogen phosphate, bentonite, baking soda, sod...

Embodiment 3

[0056] A kind of total mixed ration feed for mutton sheep in the fattening stage, the total mixed ration feed is prepared according to the following method:

[0057] 1) Take 40 parts by weight of alfalfa grass, 35 parts of corn, 8 parts of distiller's grains, 10 parts of soybean meal, 9 parts of malt root, 7 parts of corn fiber, 8 parts of cottonseed meal, 1.5 parts of molasses, 0.8 parts of stone powder, calcium hydrogen phosphate 0.8 parts, 1.5 parts of bentonite, 0.7 parts of baking soda, 1.2 parts of sodium chloride, 0.7 parts of sodium sulfate, 0.6 parts of montmorillonite, 1.2 parts of ammonium chloride, 0.15 parts of monensin, 0.6 parts of 0.5% compound premixed feed ;

[0058] The concrete preparation operation steps of described this full mixed ration feed are as follows:

[0059] 2) Mix alfalfa grass, corn, distiller's grains, soybean meal, malt root, corn fiber, cottonseed meal and molasses, grind them, pass through a 40-mesh sieve, and obtain mixed powder A;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com