Preparation method and application of graphene oxide supported quadri (4-carboxyphenyl) manganese porphyrin catalysis material

A porphyrin catalytic material, carboxyphenyl technology, applied in the direction of oxidation reaction preparation, organic compound preparation, hydrocarbon oxidation preparation of oxygen-containing compounds, etc., can solve the problem of low reuse rate, low catalytic efficiency of metal porphyrin, and oxidation conversion rate low cost, low cost, easy recycling and reuse, and low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

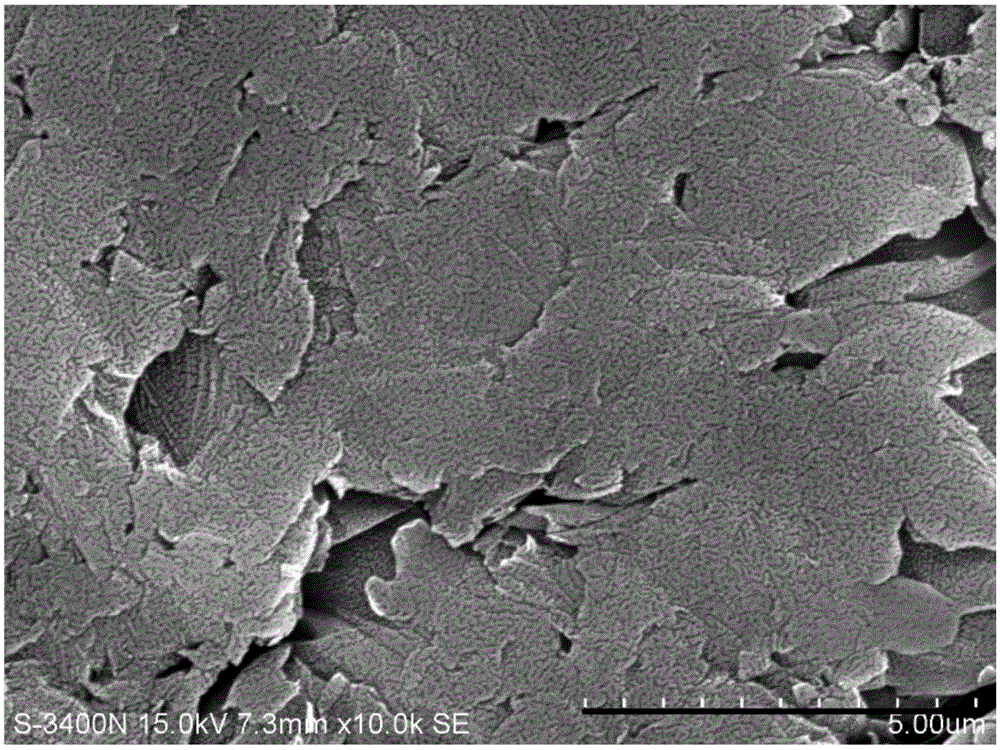

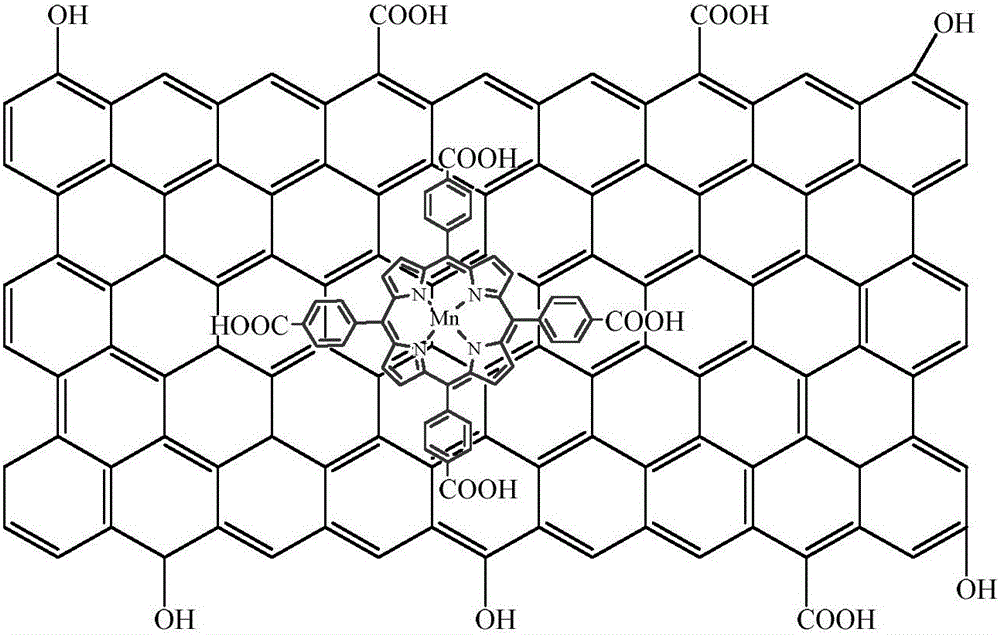

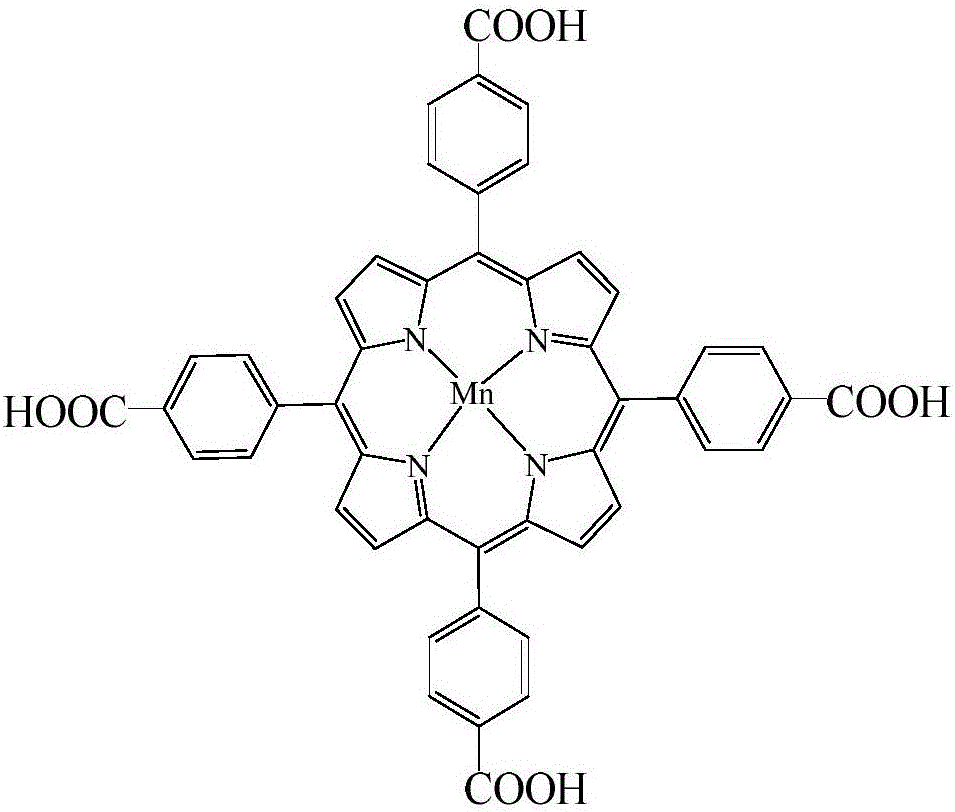

[0028] A graphene oxide immobilized four (4-carboxyphenyl) manganese porphyrin catalytic material, comprising the following raw materials in parts by weight: 550.8 parts of concentrated sulfuric acid, 12 parts of graphite powder, 6 parts of sodium nitrate, 42 parts of potassium permanganate , 2190 parts of distilled water, 180 parts of 5% hydrogen peroxide, 1500 parts of 5% hydrochloric acid, 0.030 parts of tetrakis (4-carboxyphenyl) manganese porphyrin, 4.8 parts of N.N-dimethylformamide, and 103.8 parts of toluene.

[0029] The preparation method of described graphene oxide immobilized tetrakis (4-carboxyphenyl) manganese porphyrin catalytic material comprises the following steps:

[0030] (1) Preparation of graphite oxide: Weigh 550.8 parts of concentrated sulfuric acid in a round bottom flask, add 12 parts of graphite powder and 6 parts of sodium nitrate after ice-water bath for 5 minutes, continue stirring in ice-water bath for 30 minutes, then slowly add 42 parts of perma...

Embodiment 2

[0036] Application of graphene oxide immobilized four (4-carboxyphenyl) manganese porphyrin catalytic material: Weigh 0.5 g of graphene oxide immobilized tetrakis (4-carboxyphenyl) manganese porphyrin immobilized catalytic material in Example 1, Put it into a 250mL autoclave, add 200mL toluene, control the stirring speed to 200r / min, and feed oxygen to react when the temperature rises to 150°C, the oxygen pressure is 0.8MPa, and the oxygen flow rate is 0.02m 3 / h, reaction 4.0h. The conversion rate of cyclohexane is 4.2%, the selectivity of ketone alcohol is 47.5%, and the catalyst conversion number is 7.6×104 , the ketol yield was 2.0%.

Embodiment 3

[0038] Application of graphene oxide-immobilized tetrakis(4-carboxyphenyl)manganese porphyrin catalytic material: Weigh 0.5g of graphene oxide-immobilized tetrakis(4-carboxyphenyl)manganese porphyrin catalytic material in Example 1 , put it into a 250mL autoclave, add 200mL toluene, stir at a speed of 200r / min, feed oxygen when the temperature rises to 160°C, the oxygen pressure is 0.8MPa, and the oxygen flow rate is 0.02m 3 / h, reaction 4.0h. The conversion rate of cyclohexane is 8.5%, the selectivity of ketone alcohol is 42.3%, and the catalyst conversion number is 1.5×10 5 , the ketol yield was 3.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com