Nitrogen, phosphorus and potassium microbial coated fertilizer and preparation method thereof

A microbial coating, nitrogen, phosphorus and potassium technology, applied in the field of fertilizers, can solve problems such as partial application of fertilizers, and achieve the effects of preventing soil agglomeration, good film-forming performance, and increasing dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

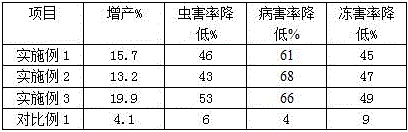

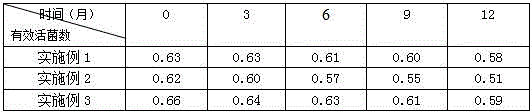

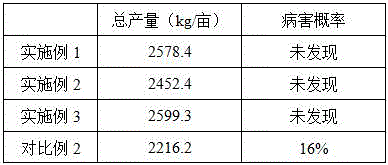

Examples

Embodiment 1

[0031] A nitrogen, phosphorus and potassium microbial coated fertilizer, comprising a pellet core, an intermediate layer and a bacterial membrane layer; the weight ratio of the pellet core, intermediate layer and bacterial membrane layer is 1:1.1:0.7, and the particle size is 4-6mm. The number of viable bacteria is more than 62 million CFU / g, the organic matter content is more than 60.5wt%, the pH is 7.1-7.2, and the content ratio of N, P and K is 2-3.5:1:1.5-2.1.

[0032] The ball core is composed of the following raw materials in parts by weight: urea 100, potassium dihydrogen phosphate 60, diammonium phosphate 50, superphosphate 18, potassium sulfate 8, plant ash 3, glutinous rice glue 18;

[0033] The middle layer is made of the following raw materials in parts by weight: 100 furfural residues, 80 distiller's grains, 57 sorghum residues, 50 edible fungus culture medium wastes, 6 Aureobasidium pullulans, 5 EM bacteria liquids, and 18 clays;

[0034] The biofilm layer is com...

Embodiment 2

[0043] A nitrogen, phosphorus and potassium microbial coated fertilizer, comprising a pellet core, an intermediate layer and a bacterial membrane layer; the weight ratio of the pellet core, intermediate layer and bacterial membrane layer is 1:1.0:0.5, and the particle size is 4-6mm. The number of viable bacteria is more than 62 million CFU / g, the organic matter content is more than 60.5wt%, the pH is 7.1-7.2, and the content ratio of N, P and K is 2-3.5:1:1.5-2.1.

[0044] The ball core is composed of the following raw materials in parts by weight: urea 100, potassium dihydrogen phosphate 55, diammonium phosphate 45, superphosphate 15, potassium sulfate 5, plant ash 2, glutinous rice glue 15;

[0045] The middle layer is made of the following raw materials in parts by weight: 100 furfural residues, 80 distiller's grains, 55 sorghum residues, 40 edible fungus culture medium wastes, 5 Aureobasidium pullulans, 3 EM bacteria liquids, and 15 clays;

[0046] The biofilm layer is com...

Embodiment 3

[0051] A nitrogen, phosphorus and potassium microbial coated fertilizer, comprising a pellet core, an intermediate layer and a bacterial membrane layer; the weight ratio of the pellet core, intermediate layer and bacterial membrane layer is 1:1.2:0.8, and the particle size is 4-6mm. The number of viable bacteria is more than 62 million CFU / g, the organic matter content is more than 60.5wt%, the pH is 7.1-7.2, and the content ratio of N, P and K is 2-3.5:1:1.5-2.1.

[0052] The ball core is composed of the following raw materials in parts by weight: urea 100, potassium dihydrogen phosphate 70, diammonium phosphate 55, superphosphate 20, potassium sulfate 10, plant ash 3, glutinous rice glue 20;

[0053] The middle layer is made of the following raw materials in parts by weight: 100 furfural residues, 80 distiller's grains, 60 sorghum residues, 60 edible fungus culture medium wastes, 8 Aureobasidium pullulans, 6 EM bacteria liquids, and 20 clays;

[0054] The biofilm layer is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com