Marine biocontrol coating and preparation method thereof

A marine organism and prevention technology, applied in the field of coatings, can solve problems such as endangering the marine environment, affecting human health, aquatic organisms poisoning, etc., and achieving the effects of stable process, favorable promotion and application, and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

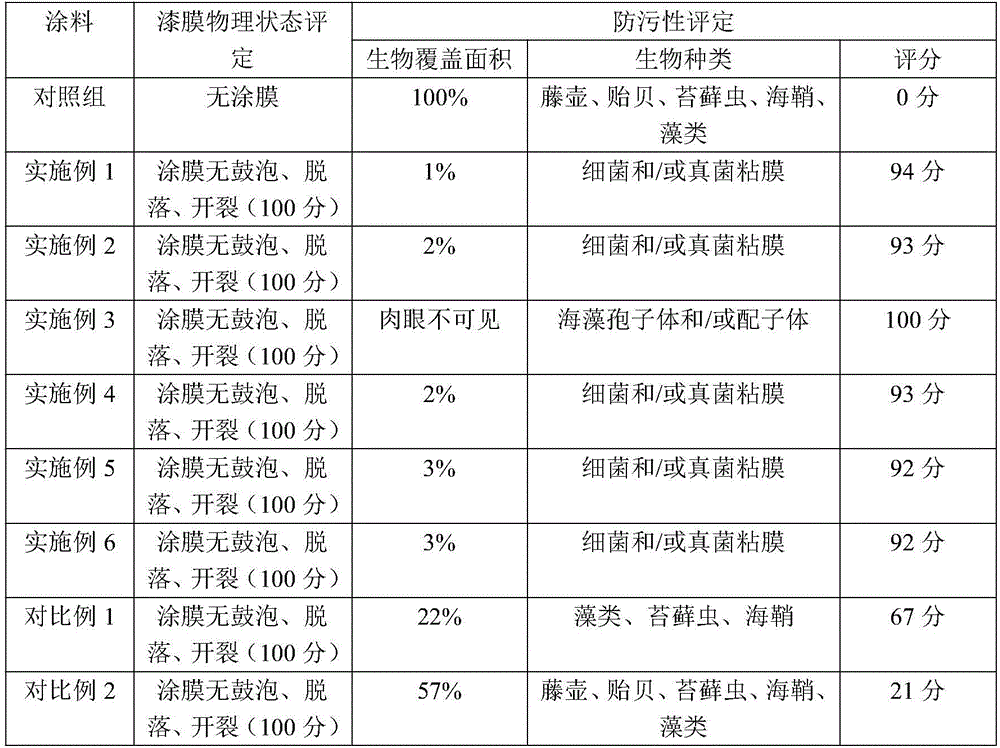

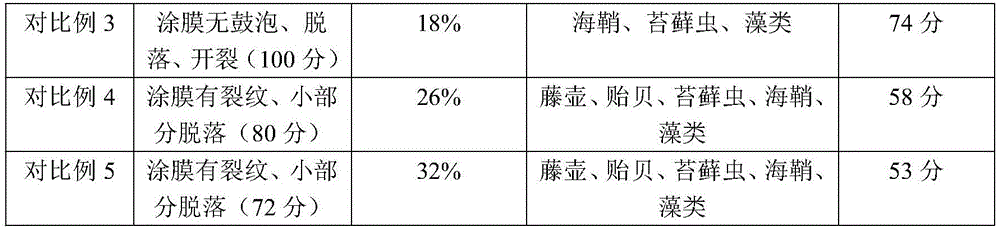

Examples

Embodiment 1

[0024] Embodiment 1, marine biological control coating and preparation thereof of the present invention

[0025] Formula: chlorinated rubber 70kg, rosin 45kg, cycloproline-3-hydroxy-2-aminobutyric acid 100kg, zinc 50kg, iron oxide red 160kg, zinc oxide 280kg, barium carbonate 3kg, magnesium oxide 1kg, trimethyl phosphate 50kg of phenol ester, 5kg of organic bentonite and 140kg of solvent; the solvent is a mixture of butyl acetate and xylene, and the weight ratio of butyl acetate and xylene is 1:5.

[0026] Preparation:

[0027] S1. Take the formula quantity of chlorinated rubber, rosin and solvent and put them into the reactor for mixing, and stir for 20min at a speed of 100r / min; then add the formula quantity of cycloproline-3-hydroxy-2-aminobutyric acid and continue Stir for 20 minutes, heat up and keep warm at 50°C for 1 hour, take it out into a dispersion tank, and cool to room temperature;

[0028] S2, then add the formula amount of Zinc, red iron oxide, zinc oxide, bar...

Embodiment 2

[0029] Embodiment 2, marine biological control coating of the present invention and its preparation

[0030] Formula: chlorinated rubber 80kg, rosin 60kg, cycloproline-3-hydroxy-2-aminobutyric acid 120kg, zinc zinc 70kg, iron oxide red 180kg, zinc oxide 320kg, barium carbonate 10kg, magnesium oxide 5kg, trimethyl phosphate 60kg of phenol ester, 15kg of organic bentonite and 160kg of solvent; the solvent is a mixture of butyl acetate and xylene, and the weight ratio of butyl acetate and xylene is 1:7.

[0031] Preparation:

[0032]S1. Take the formula quantity of chlorinated rubber, rosin and solvent and put them into the reactor for mixing, and stir for 40min at a speed of 150r / min; then add the formula quantity of cycloproline-3-hydroxy-2-aminobutyric acid, continue Stir for 40 minutes, heat up and keep warm at 55°C for 1.5 hours, take it out into a dispersion tank, and cool to room temperature;

[0033] S2, then add the formula amount of Zinc, red iron oxide, zinc oxide, b...

Embodiment 3

[0034] Embodiment 3, marine biological control coating of the present invention and its preparation

[0035] Formula: chlorinated rubber 76kg, rosin 55kg, cycloproline-3-hydroxy-2-aminobutyric acid 110kg, zinc zinc 60kg, iron oxide red 170kg, zinc oxide 300kg, barium carbonate 5kg, magnesium oxide 2kg, trimethyl phosphate 55kg of phenol ester, 10kg of organic bentonite and 150kg of solvent; the solvent is a mixture of butyl acetate and xylene, and the weight ratio of butyl acetate and xylene is 1:6.

[0036] Preparation:

[0037] S1. Take the formula quantity of chlorinated rubber, rosin and solvent and put them into the reaction kettle for mixing, and stir for 30min at a speed of 120r / min; then add the formula quantity of cycloproline-3-hydroxy-2-aminobutyric acid, continue Stir for 30 minutes, heat up and keep warm at 55°C for 1 hour, take it out into a dispersion tank, and cool to room temperature;

[0038] S2, then add the formula amount of Zinc, red iron oxide, zinc oxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com