Matrine microcapsule preparation and preparation method thereof

A technology of microcapsules and matrine, applied in the fields of botanical equipment and methods, pesticides, biocides, etc., can solve the problems of difficult to control the release rate, unsatisfactory field efficacy, and short duration of effect, etc. The effect of reducing the cost of prevention and treatment, reducing the frequency of medication, and prolonging the duration of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

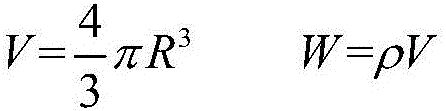

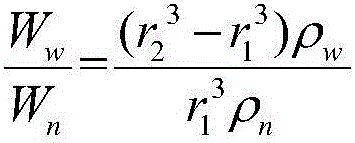

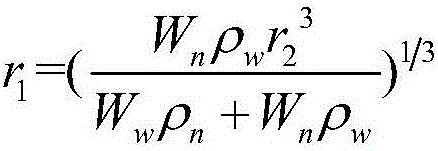

[0039] Embodiment 1. Interfacial polymerization method 0.5% matrine microcapsule suspension.

[0040] Dissolve 5 parts of matrine crude oil in 3 parts of biodiesel, mix with 4 parts of oil-soluble capsule wall material diisocyanate (TDI), and add to 120 parts of 0.5% OP-10 aqueous solution (OP-10 is octal phenol poly Oxyethylene ether-10), after stirring rapidly at 1000r / min, 4 parts of glycerol were slowly added dropwise into the reaction vessel. Reduce the rotational speed to 300r / min, and keep warm at 35°C for 30min to obtain matrine microcapsules.

[0041] Add 5 parts of wetting agent Nongru 600#, 5 parts of sodium lignosulfonate as a dispersant and 4 parts of sodium hydroxymethylcellulose as a structure regulator, and stir evenly to suspend matrine microcapsules with a thickness of 0.5% multicystic wall agent.

[0042] Microcapsule average particle size d(μm)

Embodiment 2

[0043] Example 2. In-situ polymerization method 0.5% matrine multi-capsule wall thickness microcapsule suspension.

[0044] (1) Preparation of urea-formaldehyde resin prepolymer aqueous solution: Mix and dissolve 10 parts of urea and 24 parts of formaldehyde, add 42 parts of deionized water, adjust the pH to 8.0, and keep it at 70°C for 1 hour to obtain a mass fraction of 25% urea-formaldehyde resin prepolymer. polymer (UF) solution.

[0045] (2) preparation of matrine microcapsules:

[0046] a: 5 parts of matrine crude oil are dissolved in 3 parts of biodiesel to obtain capsule core oil phase, join in 60 parts of 3% UF aqueous solution (3% refers to the mass fraction of urea-formaldehyde resin prepolymer UF, by step (1) The prepared 25% urea-formaldehyde resin prepolymer solution was diluted to obtain, hereinafter the same), adding 2.5 parts of Tween 60 and 2 parts of dispersant NNO; 1000r / min stirred and dispersed into O / W emulsion; slowly adjusted pH to 2.5, then graduall...

Embodiment 3

[0058] Example 3, in-situ polymerization method 1.0% matrine multi-capsule wall thickness microcapsule suspension.

[0059] Method is the same as example 2, get 10 parts of matrine crude oil and be dissolved in 5 parts of biodiesel in the preparation process, agent a: 60 parts of UF prepolymer (4%), 3 parts of emulsifier styrene maleic anhydride, dispersant lignin 2 parts of sodium sulfonate, stirred at 1000r / min to form O / W emulsion. Agent b: 60 parts of UF prepolymer (5%), 3 parts of emulsifier styrene maleic anhydride, 3 parts of dispersant sodium lignosulfonate, stirred and dispersed at 1200r / min to form an O / W emulsion c: UF prepolymer Body (7%) 60 parts, emulsifier styrene maleic anhydride 4 parts, dispersant sodium lignosulfonate 4 parts, 1500r / min stirring and dispersing into O / W emulsion. Other processes are the same as in Example 2, and processed into 1.0% matrine multi-capsule wall thickness microcapsule suspension.

[0060] Its particle size and capsule wall thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com