Polymerizable resin composition comprising reactive silicone compound

A technology of polymeric composition and reactive silicone, which is applied in the field of polymeric resin composition and can solve problems such as unsatisfactory reflow process and low heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0213] Hereinafter, although an Example is given and this invention is demonstrated more concretely, this invention is not limited to a following Example.

[0214] In addition, in Examples, the apparatuses and conditions used for preparation of samples and analysis of physical properties are as follows.

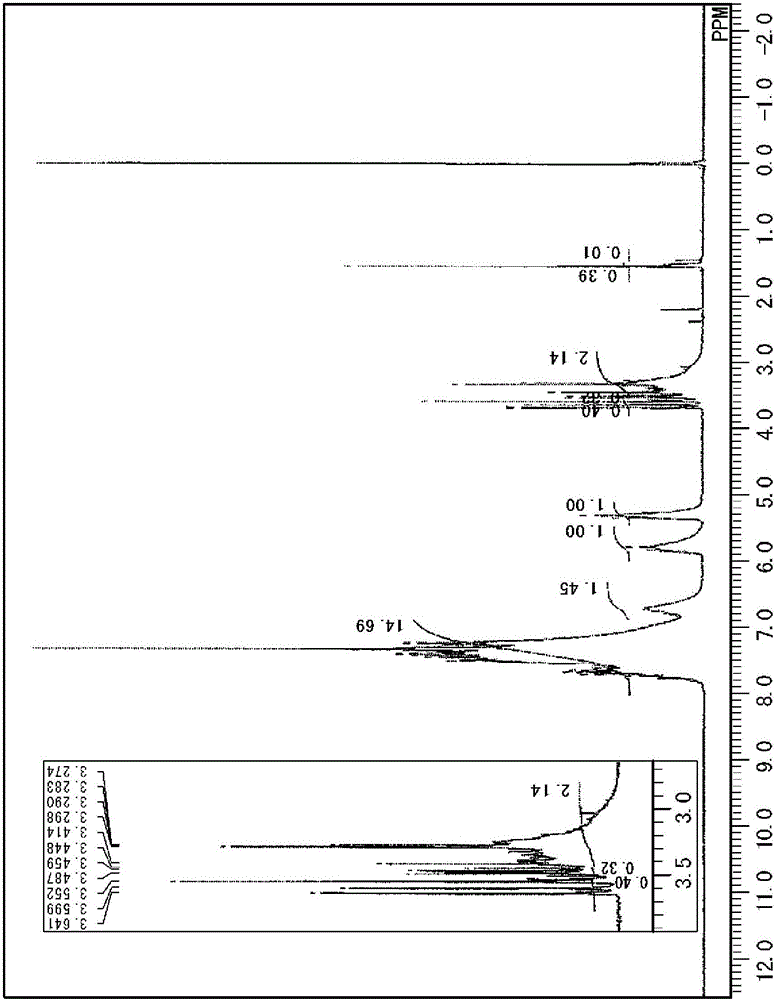

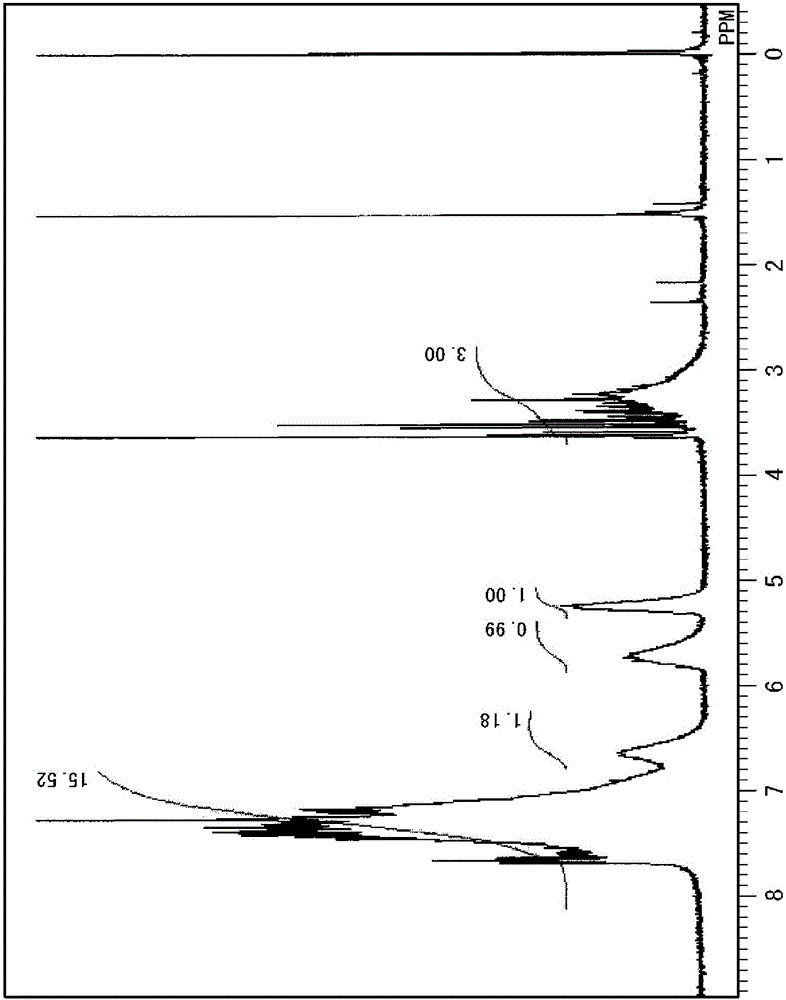

[0215] (1) 1 H NMR spectrum

[0216] Device: JNM-ECX300 manufactured by JEOL Ltd.

[0217] Determination solvent: CDCl 3

[0218] Reference substance: Tetramethylsilane (0.00ppm)

[0219] (2) Gel Permeation Chromatography (GPC)

[0220] Device: GPC system manufactured by Shimadzu Corporation

[0221] Column: Showa Denko Co., Ltd. Shodex (registered trademark) GPC KF-804L, GPC KF-803L

[0222] Column temperature: 40°C

[0223] Solvent: THF

[0224] Detector: UV (254nm)

[0225] Standard curve: standard polystyrene

[0226] (3) Stirring rotor

[0227] Device: MRC-5 manufactured by Azuwan Co., Ltd.

[0228] (4) Stirring and defoaming machine

[0229] Device: Rotati...

manufacture example 1

[0252] [Production Example 1] Production of reactive fluorine-containing organosilicon compound (F-SC)

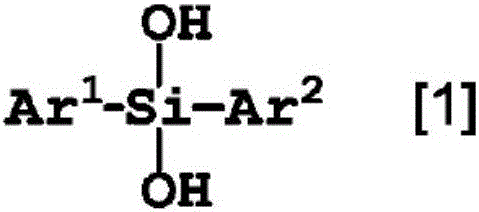

[0253] Into a 200 mL eggplant-shaped flask equipped with a condenser, 43.3 g (0.200 mol) of diphenylsilanediol [manufactured by Tokyo Chemical Industry Co., Ltd.], trimethoxy(4-vinylphenyl) silane [Shin-Etsu Chemical Co., Ltd.] Co., Ltd.] 44.0 g (0.196 mol), trimethoxy(3,3,3-trifluoropropyl) silane [Shin-Etsu Chemical Co., Ltd.] 0.873 g (0.004 mol) and toluene 35 g, using a nitrogen balloon The air in the flask was replaced with nitrogen. The reaction mixture was heated to 50° C., and 38 mg (0.2 mmol) of barium hydroxide monohydrate [manufactured by Aldrich] was added thereto. Stir directly at 50° C. for 1 hour, and then further stir at 85° C. for 5 hours to carry out dealcoholation condensation. The reaction mixture was cooled to room temperature (approximately 25° C.), and insoluble matter was removed using a membrane filter with a pore size of 0.2 μm. Toluene and by-p...

manufacture example 2

[0255] [Production Example 2] Production of Reactive Silicone Compound (SC)

[0256] Into a 1 L eggplant-shaped flask equipped with a condenser, 177 g (0.80 mol) of diphenylsilanediol [manufactured by Tokyo Chemical Industry Co., Ltd.], trimethoxy(4-vinylphenyl) silane [Shin-Etsu Chemical Co., Ltd. Co., Ltd.] 179 g (0.80 mol) and toluene 141 g, and the air in the flask was replaced with nitrogen gas using a nitrogen balloon. This reaction mixture was heated to 50° C., and 0.303 g (1.6 mmol) of barium hydroxide monohydrate [manufactured by Aldrich] was added thereto, followed by further stirring at 50° C. for 2 days to conduct dealcoholation condensation. The reaction mixture was cooled to room temperature (approximately 25° C.), and insoluble matter was removed using a membrane filter with a pore size of 0.2 μm. Using a rotary evaporator, toluene and by-product methanol were distilled off from the reaction mixture under reduced pressure at 50° C. to obtain 305 g of a colorles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com