Method for quickly improving biological adhesiveness of laser patterned PDMS surface

A bio-adhesion and patterning technology is applied in the field of laser patterning PDMS surface to rapidly improve bio-adhesion and improve the bio-adhesion of PDMS surface. Adaptability, the effect of improving bioadhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

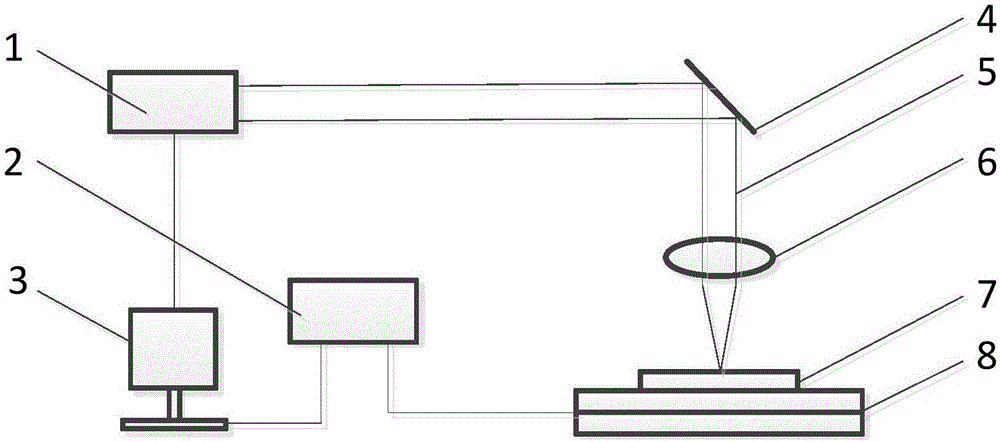

[0037] like figure 1 As shown, a laser patterning PDMS surface rapid improvement method of bio-adhesion, the PDMS surface will form a microstructure after laser action, providing a good environment for cell attachment growth;

[0038] The microstructure can immobilize proteins, cell growth factors, enzymes and nucleic acids.

[0039] The laser (1) generates a high-energy pulsed laser beam, and after the high-energy pulsed laser beam passes through the reflector (4), it is focused to the surface of the PDMS (7) through a convex lens (6). Under the action of energy and impact force, photothermal action and photochemical action occur on the surface of PDMS (7), and instantaneous vaporization or splashing, thereby forming microstructures on the surface of PDMS (7).

[0040] Specifically, PDMS is placed on the three-dimensional micro-working platform, and the vertical movement of the three-dimensional micro-working platform (8) is controlled by the computer (3) and the motion con...

Embodiment 2

[0042] like figure 1 As shown, a method for rapidly improving bioadhesion on the surface of laser patterned PDMS, through chemical modification or structural modification of the PDMS surface after laser action, thereby improving bioadhesion;

[0043] The laser (1) generates a high-energy pulsed laser beam, and after the high-energy pulsed laser beam passes through the reflector (4), it is focused to the surface of the PDMS (7) through a convex lens (6). Under the action of energy and impact force, the surface of PDMS(7) undergoes chemical or structural modification, thereby improving bioadhesion.

[0044] Specifically, PDMS is placed on the three-dimensional micro-working platform, and the vertical movement of the three-dimensional micro-working platform (8) is controlled by the computer (3) and the motion control system (2) to adjust the distance between the PDMS (7) surface and the laser focus. distance; through the computer (3) and the motion control system (2) to control...

Embodiment 3

[0046] like figure 1 As shown, a method of laser patterning PDMS surface to rapidly improve bioadhesion,

[0047] (1) PDMS substrate production: PDMS prepolymer and curing agent are mixed at a ratio of 10:1, and fully stirred for 10 minutes; the mixture is poured into the mold; because more air is mixed during the stirring, a vacuum pump is required Carry out vacuum pumping for half an hour; then put the mixture into a horizontal drying oven, set the temperature at 65 degrees Celsius, and accelerate curing for 4 hours to obtain a PDMS substrate; take out the PDMS substrate and seal it up.

[0048] (2) The laser is an ultraviolet pulsed laser with a wavelength of 355nm. When the laser is turned on, the laser (1) produces a high-energy pulsed laser beam. After the high-energy pulsed laser beam passes through the reflector (4), it is focused to PDMS (7) by a convex lens (6). ) surface, under the action of high energy and impact force brought by the high-energy pulsed laser beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com