A kind of hydroxyl acrylic acid emulsion with core-shell structure and its preparation method and application

A hydroxyacrylic acid, core-shell structure technology, applied in the direction of coating, can solve the problems of not being able to improve the resistance, the fullness of the paint film, the flexibility, and the inability to be used for metal baking paint, etc. Low usage rate, low VOC content, and the effect of improving hardness and resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a method for preparing the above-mentioned hydroxyacrylic acid emulsion with a core-shell structure. First, a core layer pre-emulsion is prepared from part of the monomers forming the core layer of the emulsion particle and an emulsifier, and polymerized in the presence of an initiator. The core layer emulsion is prepared, and then the shell layer mixed monomer is evenly added dropwise, polymerized in the presence of an initiator, neutralized, filtered, and discharged to obtain a hydroxyacrylic acid emulsion with a core-shell structure. The specific steps are as follows:

[0041] (1) Preparation of the nuclear layer pre-emulsion: Part of the monomer ①, part of the monomer ④ and all the monomer ⑤ are uniformly dispersed in water under the action of an emulsifier to obtain a nuclear layer pre-emulsified monomer mixture;

[0042] (2) Preparation of shell pre-emulsion: the remaining monomers ①, ④ and all monomers ②, ③ are uniformly dispers...

Embodiment 1-3

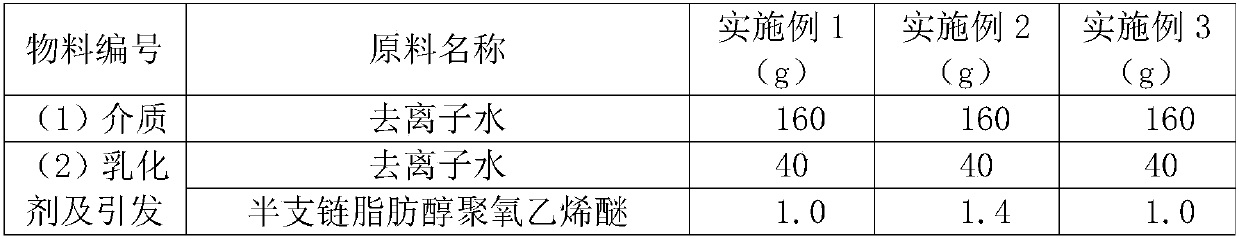

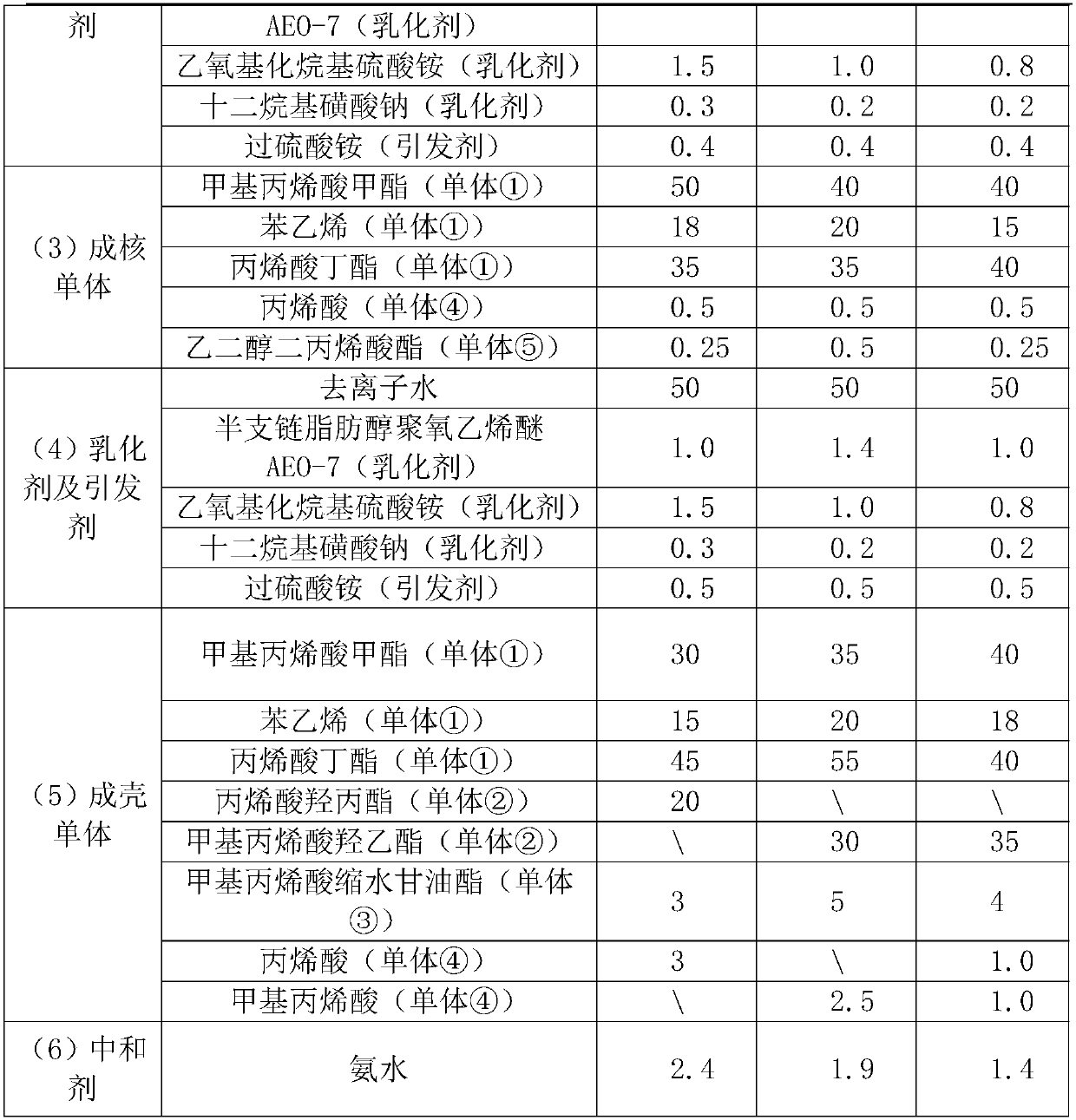

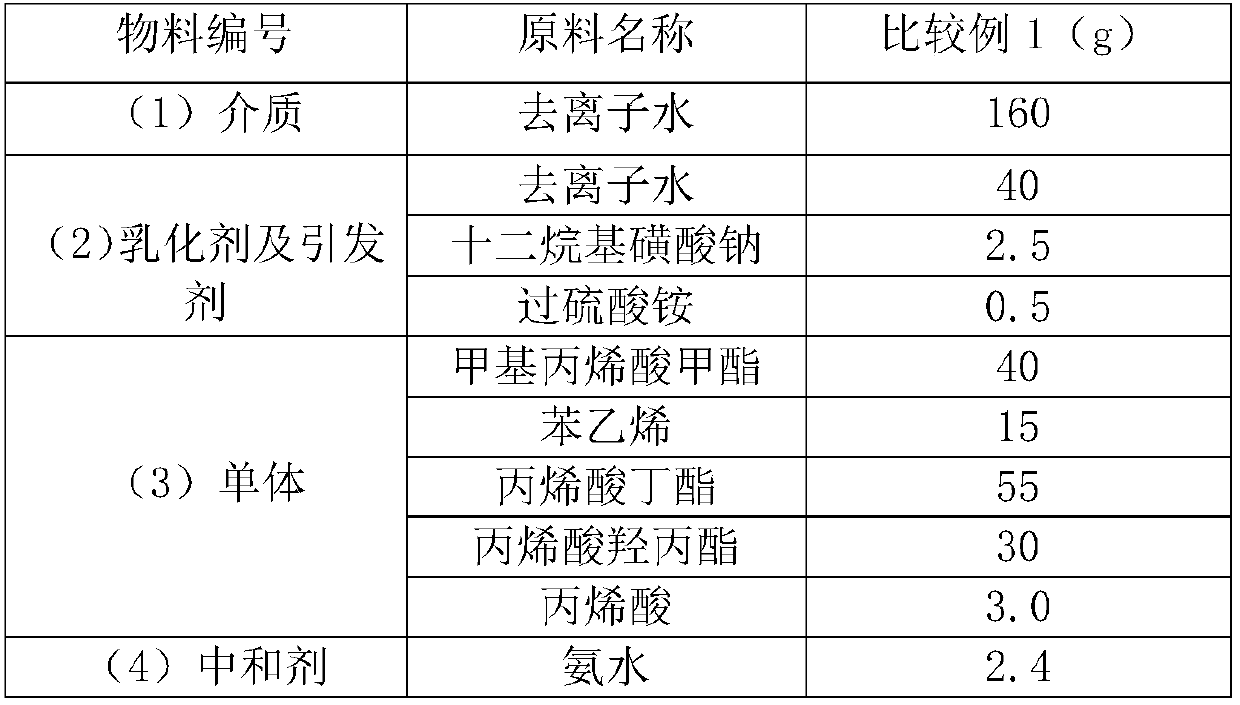

[0049] The recipe is shown in Table 1

[0050] Table 1 is the composition and consumption of the required material of embodiment 1-3

[0051]

[0052]

[0053] Embodiment 1-3 synthetic technique:

[0054] Add material (1) and 30% material (2) in the 500ml four-neck flask, be warming up to 80 ℃, add 10% material (3) and polymerize for 0.5 hour to obtain seed emulsion, then drop remaining material (2) in 1 hour ) and the mixed solution of the material (3), keep it warm for 0.5 hours, then add the mixed solution of the material (4) and the material (5) dropwise, drop it in 2 hours, keep it warm for 2 hours after dropping it, then cool down to 40°C, add the material ( 6) Neutralize, stir evenly, filter and discharge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com