Poly(monothiocarbonic ester) containing crystals and preparation method of poly(monothiocarbonic ester)

A technology of polymonothiocarbonate and crystal, which is applied in the field of polymonothiocarbonate containing crystals and its preparation, and can solve problems such as unsatisfactory crystalline polymers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

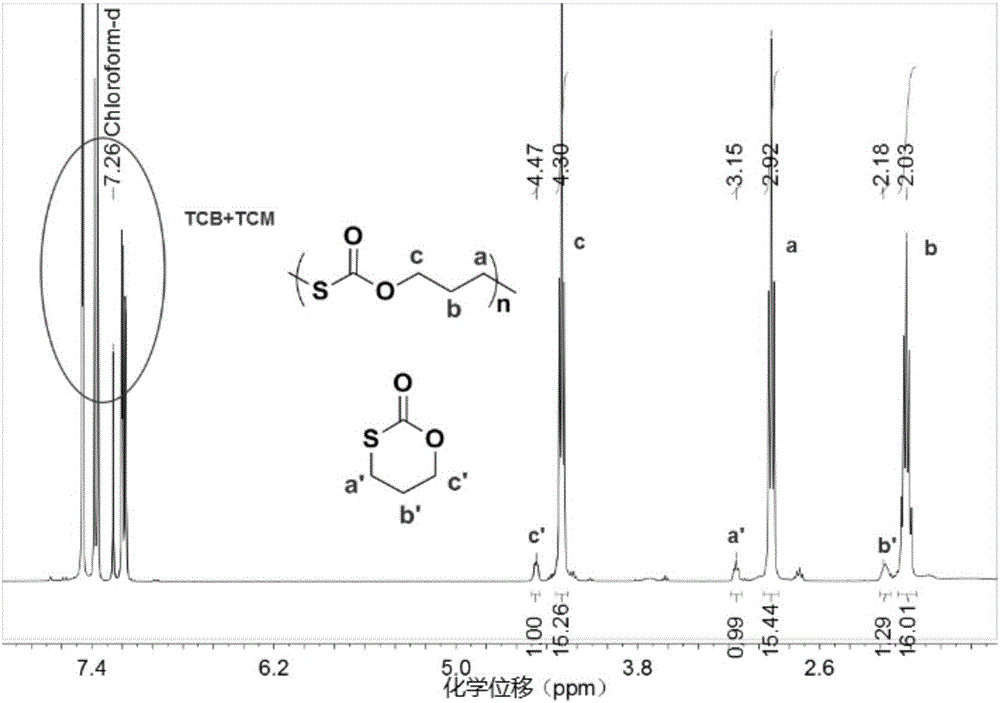

[0041] Embodiment 1 (Salen) CrX catalyst catalyzes COS / OX one-pot copolymerization into polymonothiocarbonate

[0042] Before the polymerization reaction, the 10mL autoclave was dehydrated at 110°C for about 2 hours and cooled to room temperature in a desiccator; several masses of SalenCrX catalyst 1a and cocatalyst bis(triphenylphosphorane base) ammonium chloride ([PPN]Cl), the two are equimolar; the molar ratio of the catalyst to the monomer OX is 1 / 250; then add 3.8g COS and 2.0mL OX (the molar ratio of COS to OX is 2:1). Then the autoclave was closed and placed in an oil bath at 120° C. for 4 h under autogenous pressure. After the reaction was completed, it was cooled to room temperature, and the yellow product was taken out. The crude product was first dissolved by heating to 130°C with DMSO, and then the polymer was precipitated in methanol. The white product was obtained by repeated washing three times, and dried in vacuo to constant weight. Calculate the conversion r...

Embodiment 2

[0043] Embodiment 2 (Salen) CrX catalyst catalyzes COS / OX one-pot copolymerization into polymonothiocarbonate

[0044] Before the polymerization reaction, the 10mL autoclave was dehydrated at 110°C for about 2 hours and cooled to room temperature in a desiccator. Several masses of SalenCrX catalyst 1a and co-catalyst 1,5,7-diazabicyclo[5.4.0]undec-7-decene (TBD) were sequentially added into the reactor, both in equal molar numbers. The molar ratio of catalyst to monomer OX is 1 / 5000. Then add 4.8g COS and 1.0mL OX (the molar ratio of COS to OX is 5:1). Then the autoclave was closed and placed in an oil bath at 150° C. for 0.5 h under autogenous pressure. After the reaction was completed, it was cooled to room temperature, and the yellow product was taken out. The crude product was first dissolved by heating to 130°C with DMSO, and then the polymer was precipitated in methanol. The white product was obtained by repeated washing three times, and dried in vacuo to constant wei...

Embodiment 3

[0045] Embodiment 3 (Salen) CrX catalyst catalyzes COS / OX one-pot copolymerization into polymonothiocarbonate

[0046] Before the polymerization reaction, the 10mL autoclave was dehydrated at 110°C for about 2 hours and cooled to room temperature in a desiccator. Add several qualities of SalenCrX catalyst 1b and co-catalyst cetyltrimethylammonium bromide (CTAB) in the reactor in sequence, both in equimolar numbers. The molar ratio of catalyst to monomer OX is 1 / 2500. Then add 1.4g COS and 3.0mL OX (the molar ratio of COS to OX is 0.5:1). Then the autoclave was closed and placed in an ice bath at 0 °C for 24 h under autogenous pressure. After the reaction was completed, it was cooled to room temperature, and the yellow product was taken out. The crude product was first dissolved by heating to 130°C with DMSO, and then the polymer was precipitated in methanol. The white product was obtained by repeated washing three times, and dried in vacuo to constant weight. Calculate the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com