Method for preparing hexagonal boron nitride (h-BN) and hybrid structure thereof through plasma enhanced chemical vapor deposition (PECVD)

A technology of hexagonal boron nitride and plasma, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the failure to realize the continuous regulation of the band gap of the hexagonal boron nitride hybrid structure and the limitation of material selection , high energy consumption and other issues, to achieve the effect of good quality, lower temperature range, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

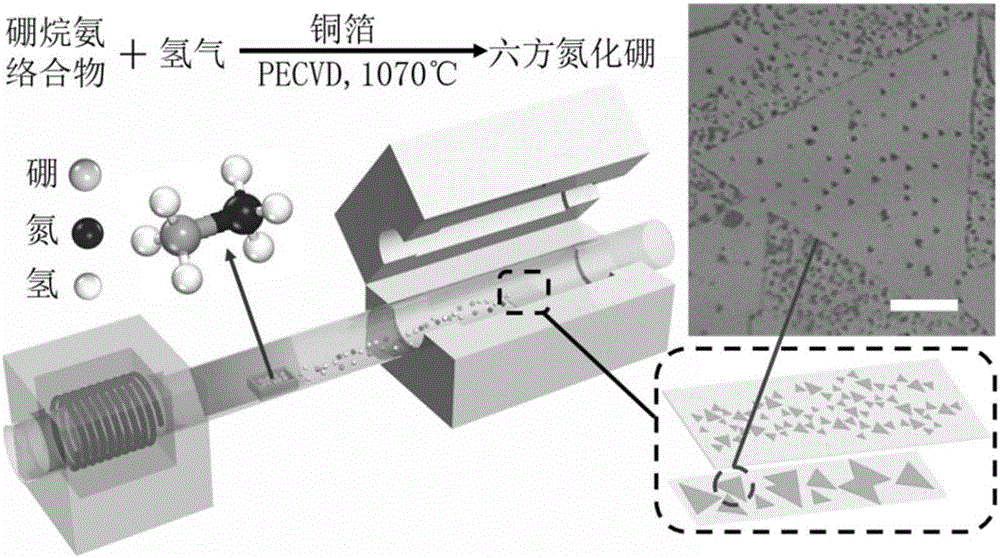

[0042] Example 1, preparation of single-layer hexagonal boron nitride single crystal and thin film on the surface of copper foil

[0043] In the first step, the copper foil and borane ammonium complex are placed in a quartz boat, and then placed in a plasma-enhanced chemical vapor deposition system and vacuumed;

[0044] In the second step, the reaction furnace is heated to 1070°C, and H 2 , and then move the copper foil to the center of the furnace;

[0045] The third step is to introduce hydrogen with a flow rate of 200sccm, and adjust the system pressure to 570Torr for heat treatment for 4 hours;

[0046] The fourth step is to adjust the system pressure to 1.05Torr, and turn on the plasma generator, set the power to 60W, the hydrogen flow rate to 200sccm, and the growth time to 30min to grow hexagonal boron nitride;

[0047] The fifth step is to turn off the heating power supply, continue to feed the gas, and cool down to room temperature rapidly.

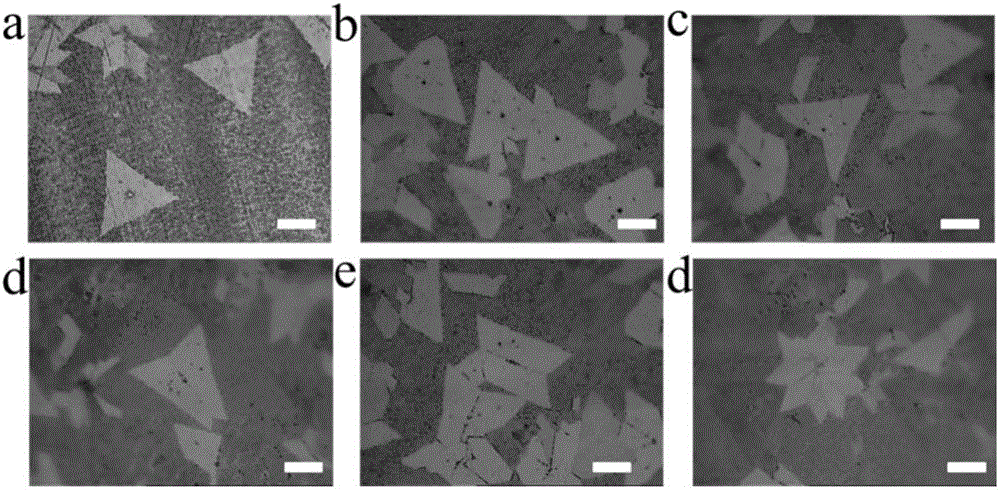

[0048] The light micr...

Embodiment 2

[0049] Example 2, using graphene single crystal to prepare hexagonal boron nitride hybrid structure on the surface of copper foil

[0050] In the first step, place the copper foil and borane ammonium complex grown on graphene single crystal into a quartz boat, and then put it into a plasma-enhanced chemical vapor deposition system and vacuumize;

[0051] In the second step, the reaction furnace is heated to 1070°C, and H 2 , and then move the copper foil that has grown the graphene single crystal to the center of the furnace;

[0052] The third step is to introduce hydrogen gas with a flow rate of 200sccm, adjust the system pressure to 200Torr, and perform heat treatment for 10 minutes;

[0053] The fourth step is to adjust the system pressure to 1.05Torr, and turn on the plasma generator, set the power to 80W, the hydrogen flow rate to 200sccm, and the growth time to 40min, using graphene single crystal to prepare hexagonal boron nitride hybrid structure;

[0054] The fifth s...

Embodiment 3

[0056] Example 3, using a single-layer graphene film to prepare a hexagonal boron nitride hybrid structure on the surface of copper foil

[0057] In the first step, put the copper foil and borane ammonium complex grown on single-layer graphene into a quartz boat, and then put it into a plasma-enhanced chemical vapor deposition system and vacuumize;

[0058] In the second step, the reaction furnace is heated to 1070°C, and H 2 , and then move the copper foil that has grown a single-layer graphene film to the center of the furnace;

[0059] The third step is to introduce hydrogen gas with a flow rate of 200sccm, adjust the system pressure to 200Torr, and perform heat treatment for 10 minutes;

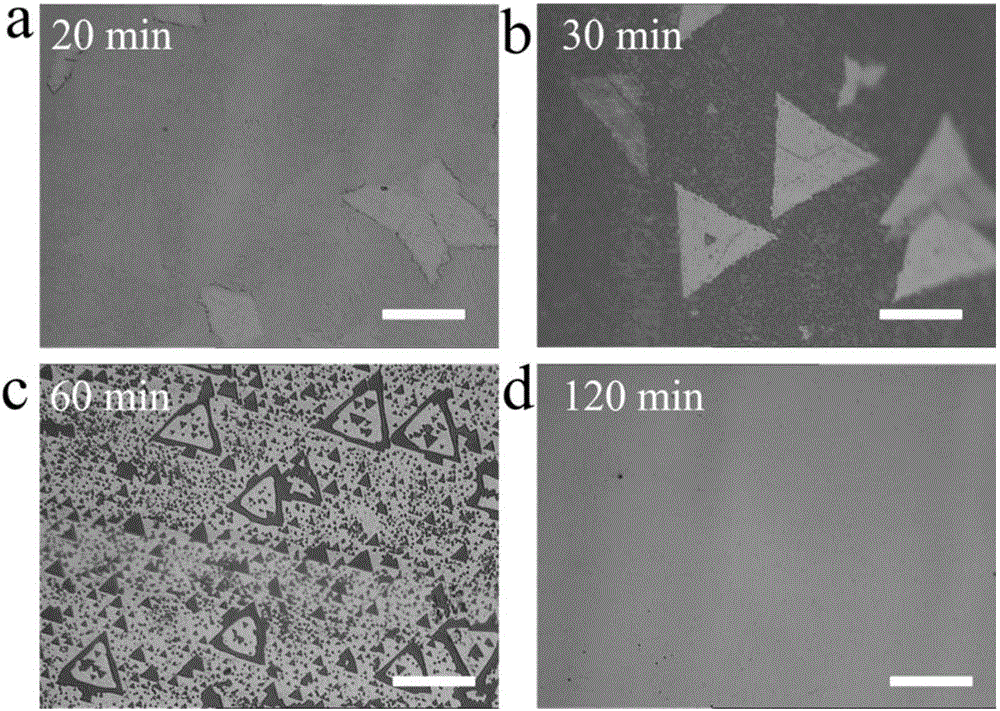

[0060] The fourth step is to adjust the system pressure to 1.05Torr, and turn on the plasma generator, set the power to 60W, the hydrogen flow rate to 200sccm, and the growth time to 5~100min, and use single-layer graphene to prepare hexagonal boron nitride hybrid structure;

[0061] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com