Method for improving ash packing effect of cigarette paper

A cigarette paper and a modified technology are applied in the field of preparation of cigarette paper and its accessories, and achieve the effects of easy operation, reduced loss and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

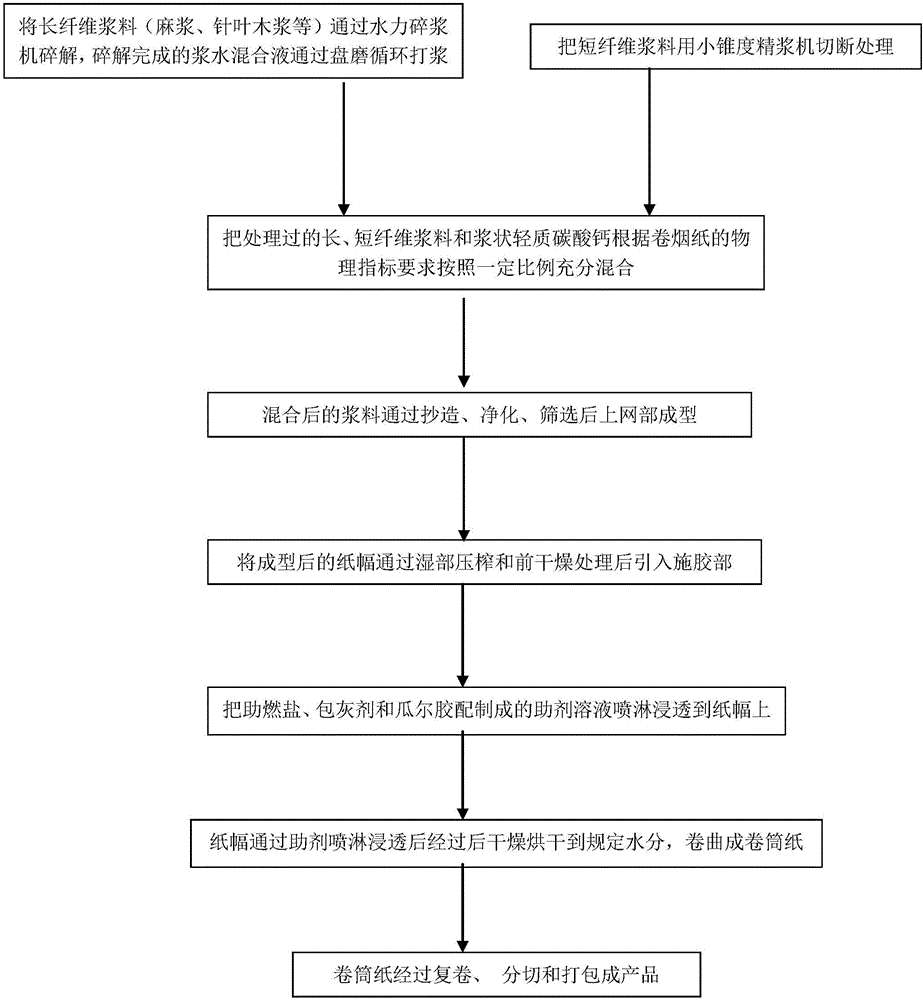

Method used

Image

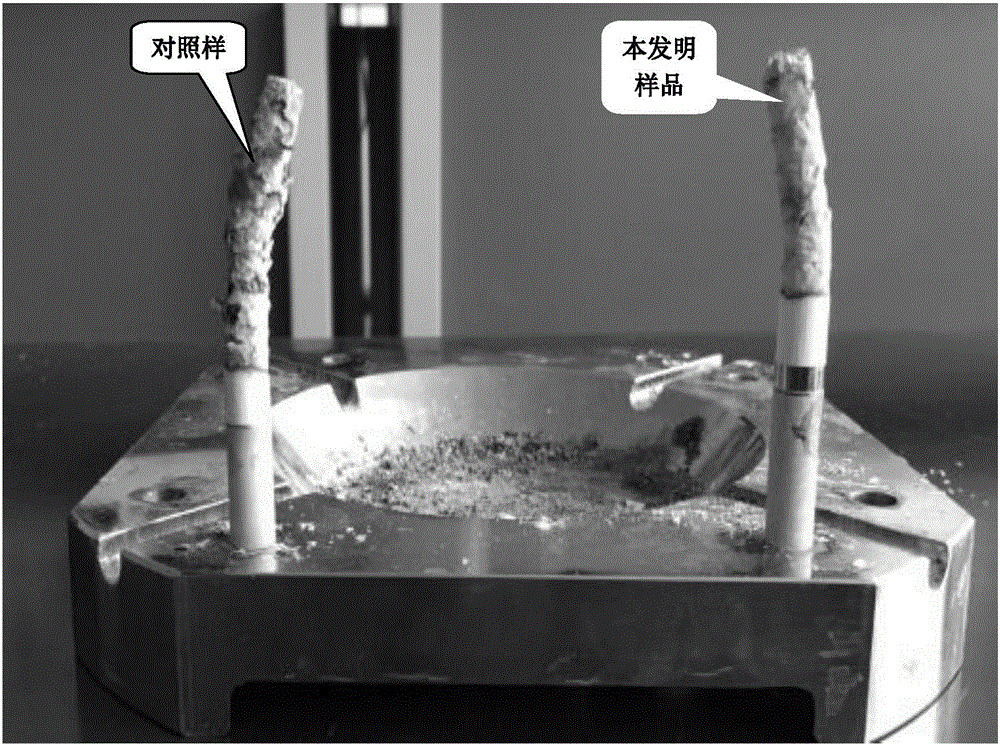

Examples

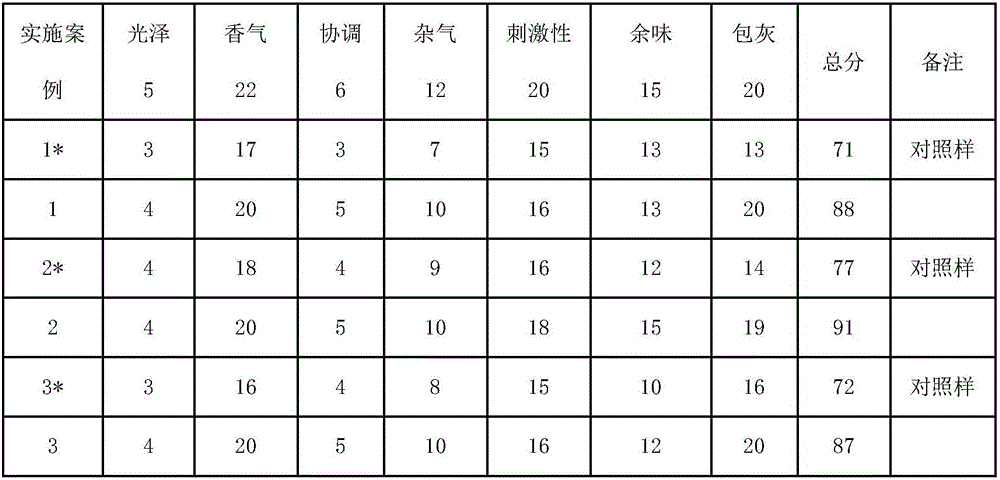

Embodiment 1

[0024] Take 800kg of coniferous wood fiber raw materials, go through double-disc mill cycle beating, control the beating degree between 87°SR~90°SR, and control the wet weight between 11g~13g; take 2000kg hardwood fiber raw materials, go through small taper refining pulping Machine cutting treatment; fully mix the beating-treated softwood pulp and cut-treated hardwood pulp with 1500kg pulpy light calcium carbonate. After sizing, the mixed pulp goes through the wire section, press section, and pre-drying treatment in the general papermaking production line, and then enters the sizing press section, where the cigarette base paper is sprayed and soaked for sizing. The composition of the sizing aid is 15kg potassium citrate, 10kg sodium malate, 25kg sodium tartrate or modified β-ring powder, 100kg of guar gum solution that has been dissolved in hot water to a concentration of 4wt%, and 600kg of pure aqueous solution. Prepared by mixing. After the cigarette base paper is sprayed a...

Embodiment 2

[0026] Take 300kg of hemp fiber raw material and 500kg of coniferous wood fiber raw material, beating through a double-disc mill cycle, the beating degree is controlled between 88°SR~90°SR, and the wet weight is controlled between 9g~11g; take 2000kg of hardwood fiber raw material, After being cut by a small taper refiner; the softwood pulp that has been beaten and the hardwood pulp that has been cut are fully mixed with 1600kg of pulpy light calcium carbonate. The mixed slurry goes through the wire section, press section, and pre-drying treatment in the general papermaking production line, and then enters the sizing press section, where the cigarette base paper is sprayed and soaked for sizing. The sizing aid is prepared by fully mixing 20kg of potassium malate, 4kg of sodium citrate, 26kg of sodium tartrate or modified beta ring powder, 120kg of guar gum solution with a concentration of 4wt%, and 600kg of pure aqueous solution. After spraying and sizing, the base paper of ci...

Embodiment 3

[0028] Take 2500kg of hemp fiber raw material, beating through double-disc mill cycle, the beating degree is controlled between 84°SR-87°SR, and the wet weight is controlled between 8g-10g; the beating-treated hemp fiber and 3000kg pulp light Calcium carbonate is mixed well. The mixed slurry goes through the wire section, press section, and pre-drying treatment in the general papermaking production line, and then enters the sizing press section, where the cigarette base paper is sprayed and soaked for sizing. The sizing aid is prepared by fully mixing 13kg of potassium citrate, 13kg of sodium malate, 22kg of sodium tartrate or modified beta ring powder, 125kg of guar gum solution with a concentration of 4wt%, and 600kg of pure aqueous solution. After spraying and sizing, the base paper of cigarettes is dried through post-drying, so that the moisture content of the cigarette paper reaches about 4.5wt%, and then the cigarette paper is rewound, cut, and packaged into finished pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com