A kind of biological patch and preparation method

A biological patch and patch technology, applied in the field of medical devices, can solve the problems of long peritoneal time, expensive process, easy to cause adhesion, etc., and achieve the effects of increasing surface area, simple process, and enhancing cell adhesion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

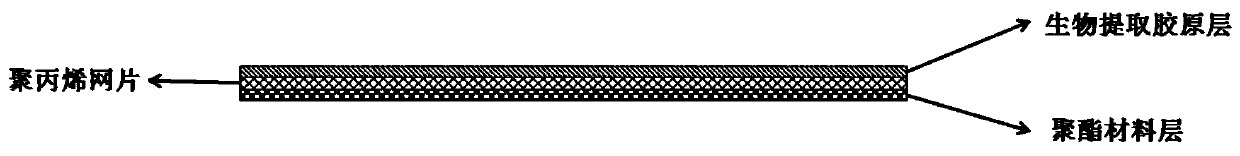

[0037] Preparation of bio-patch

[0038] 1. Dissolving collagen extracted from bovine Achilles tendon in hexafluoroisopropanol to obtain a collagen solution with a concentration of 5 wt %;

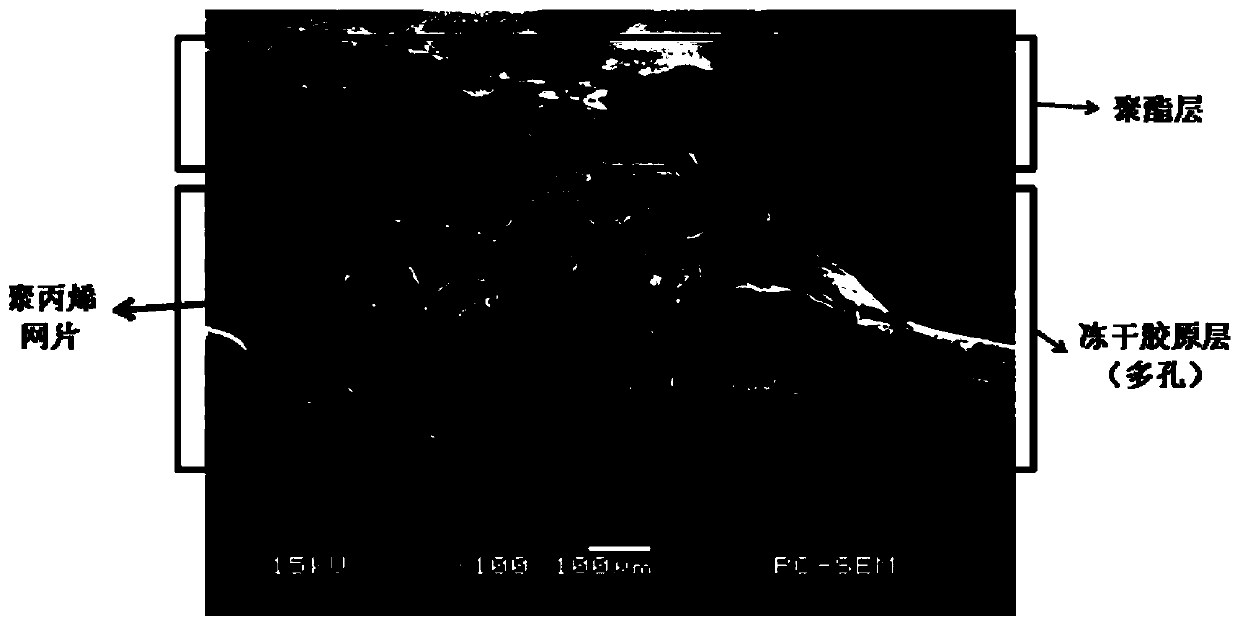

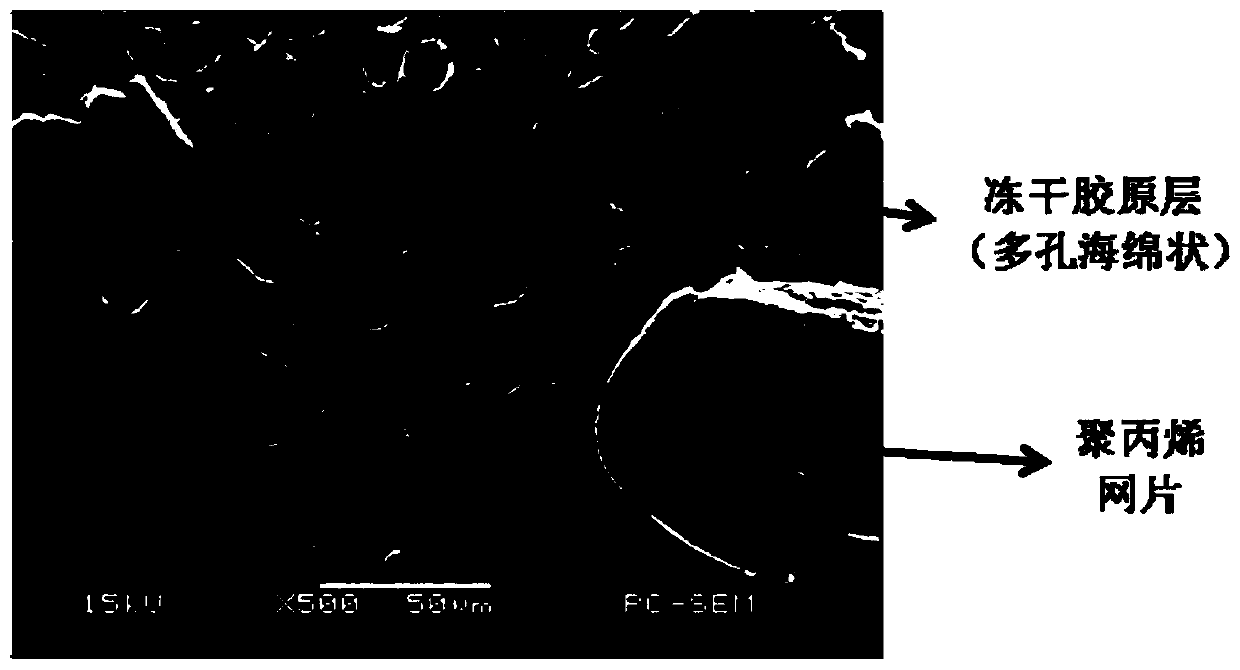

[0039] 2. Place the polypropylene (PP) mesh in a collagen solution with a concentration of 5wt%, and freeze-dry it to obtain a collagen-polypropylene membrane;

[0040] 3. PLA-PCL copolymer (70% PLA, 30% PCL copolymer) is dissolved in acetone and made concentration is the polymer solution of 10wt%;

[0041] 4. Immerse the collagen-polypropylene membrane in the PLA-PCL copolymer acetone solution, so that the PLA-PCL copolymer acetone solution enters the pores of the collagen-polypropylene membrane, and use a low-temperature decompression process to obtain anti-adhesion regeneration after drying biological patch;

[0042] 5. Carry out radiation sterilization to the obtained biological patch.

[0043] The biologically extracted collagen used in this example is derived from extracts of pig ...

Embodiment 2

[0045] 1. Dissolving biologically extracted collagen in dioxane to obtain a collagen solution with a concentration of 5wt%;

[0046] 2. Put the polypropylene (PP) mesh into the collagen solution, and freeze-dry to obtain the collagen-PP membrane;

[0047] 3. What is the concentration of PHB dissolved in ethyl acetate? wt% polymer solution;

[0048] 4. Immerse the collagen-PP membrane in the PLCL solution but not completely, let the PHB solution enter the pores of the collagen-PP membrane, adopt a low-temperature decompression process, and dry to obtain an anti-adhesion regenerative biological patch;

[0049] 5. Carry out radiation sterilization to the obtained biological patch.

[0050] The biologically extracted collagen used in this example is skin collagen, which is derived from pig skin. The layers of the patch prepared in this example are well bonded, cut without delamination, soaked in 37°C physiological saline solution for 24 hours without delamination, and very soft. ...

Embodiment 3

[0052] 1. Dissolving the biologically extracted collagen in DMSO to obtain a collagen solution with a concentration of 5wt%;

[0053] 2. Put the polypropylene (PP) mesh into the collagen solution, and freeze-dry to obtain the collagen-PP membrane;

[0054] 3. What is the concentration of dissolving PLA in ethanol? wt% polymer solution;

[0055] 4. Immerse the collagen-PP membrane in the PLA solution, but not completely, so that the PLA solution enters the pores of the collagen-PP membrane, adopt a low-temperature decompression process, and dry to obtain an anti-adhesion regenerative biological patch;

[0056] 5. Carry out radiation sterilization to the obtained biological patch.

[0057] The biologically extracted collagen used in this example is collagen, which is derived from bovine bone. The layers of the patch prepared in this example are well bonded, cut without delamination, soaked in 37°C physiological saline solution for 24 hours without delamination, and very soft....

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com