Preparation method of magnetic heteropoly acid-graphene composite catalytic material

A graphene composite and catalytic material technology, which is applied in the field of preparation of new heteropolyacid-graphene composite catalytic materials, can solve the problems of small specific surface area, low pollution rate and difficult recovery of heteropolyacid, and achieve uniform appearance, The effect of low preparation cost and simple equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

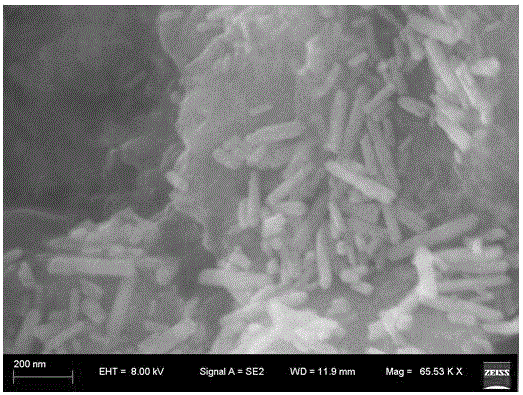

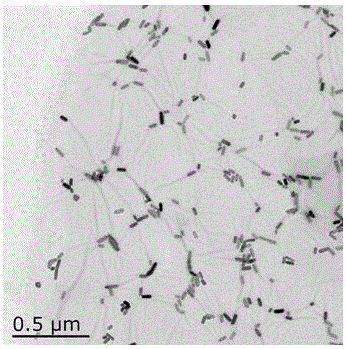

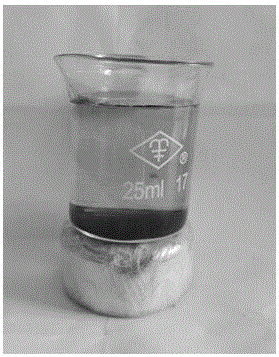

[0027] 1) Preparation of magnetic carrier material: ultrasonically dissolve 40 mg of graphene oxide in 25 ml of distilled aqueous solution, stir for 30 min, then add 0.68 g of ferrous sulfate to the graphene solution, then add 0.20 g of sodium hydroxide, 1.50 g of polyvinylpyrrolidone g and urea 1.80g. The above solution was transferred to a reaction kettle, and the hydrothermal reaction was carried out at 180° C. for 6 hours. After the reaction, the product was filtered, washed, dried at 60° C. and the solid was collected to obtain a magnetic carrier material.

[0028] 2) Preparation of heteropoly acid-Na 12 [WZn 3 (ZnW 9 o 34 ) 2 ]Materials: Dissolve 6.35g of sodium tungstate in 50ml of distilled water, heat and stir at 85°C until completely dissolved; dissolve 1.50g of zinc nitrate in 5ml of distilled water, add to the above solution, condense and reflux at 85°C for 2 hours After the reaction is finished, filter and collect the filtrate, wait for crystallization, and o...

Embodiment 2

[0031] 1) Preparation of magnetic carrier material: ultrasonically dissolve 80 mg of graphene oxide in 50 ml of distilled aqueous solution, stir for 30 min; then add 1.36 g of ferrous sulfate into the graphene solution, then add 0.40 g of sodium hydroxide, 3.00 g of polyvinylpyrrolidone g and urea 3.60g. The above solution was transferred to a reaction kettle, and the hydrothermal reaction was carried out at 180° C. for 6 hours. After the reaction, the product was filtered, washed, dried at 60° C. and the solid was collected to obtain a magnetic carrier material.

[0032] 2) Preparation of heteropoly acid-Na 12 [WZn 3 (ZnW 9 o 34 ) 2 ] Material: Dissolve 12.70g of sodium tungstate in 100ml of distilled water, heat and stir at 85°C until completely dissolved; dissolve 3.00g of zinc nitrate in 10ml of distilled water, add to the above solution, condense and reflux at 85°C for 2 hours After the reaction is finished, filter and collect the filtrate, wait for crystallization, ...

Embodiment 3

[0035] 1) Preparation of magnetic carrier material: ultrasonically dissolve 160 mg of graphene oxide in 100 ml of distilled aqueous solution, stir for 30 min, then add 2.72 g of ferrous sulfate to the graphene solution, then add 0.80 g of sodium hydroxide, 6.00 g of polyvinylpyrrolidone g and urea 7.20g. The above solution was transferred to a reaction kettle, and the hydrothermal reaction was carried out at 180° C. for 6 hours. After the reaction, the product was filtered, washed, dried at 60° C. and the solid was collected to obtain a magnetic carrier material.

[0036] 2) Preparation of heteropoly acid-Na 12 [WZn 3 (ZnW 9 o 34 ) 2 ]Materials: Dissolve 25.40g of sodium tungstate in 200ml of distilled water, heat and stir at 85°C until completely dissolved; dissolve 6.00g of zinc nitrate in 20ml of distilled water, add to the above solution, condense and reflux at 85°C for 2 hours After the reaction is finished, filter and collect the filtrate, wait for crystallization, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com