Method for preparing mesoporous silica core-shell microspheres

A technology of mesoporous silica and core-shell microspheres, applied in silica, silica and other directions, can solve the problems of affecting separation efficiency, prone to agglomeration, and reducing the effective surface area of chromatographic applications, and achieves a simple and easy preparation process. Controlled and amplified, mildly conditioned effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

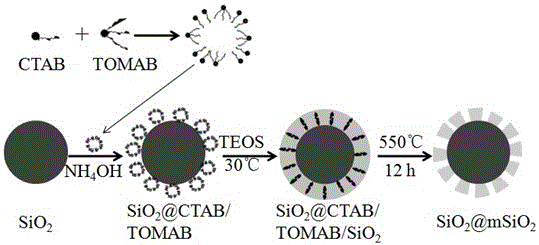

[0038] Example 1 Preparation of micron-scale surface porous silica core-shell microspheres ( figure 1 )

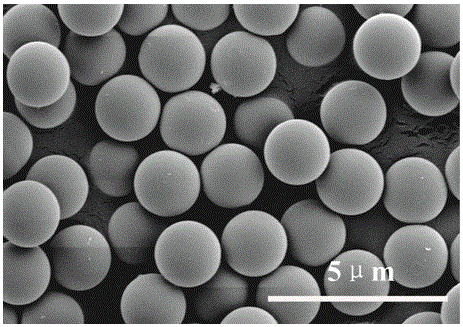

[0039] (1) Preparation of solid silica microspheres

[0040] According to reference [H. Nakabayashi, A. Yamada, M. Noba, Y. Kobayashi, M. Konno, D. Nagao, Langmuir 26 (2010) 7512-7515] preparation of micron-sized silica solid microspheres, a typical method For: Preparation of liquid A: Take a clean reagent bottle, add 200-300 mL of absolute ethanol, appropriate amount of water, ammonia water and appropriate amount of electrolyte to make a 300 mL mixed solution, and ultrasonicate for 10 min for later use.

[0041] Preparation of solution B: add an appropriate amount of TEOS and a certain amount of absolute ethanol to make a diluted solution, and ultrasonically for 10 min for later use.

[0042] Add liquid A to a 1000 mL three-necked flask, slowly add liquid B dropwise at a controlled rate within 0.8 mL / min, and react at a certain temperature at a certain stirring speed. A...

Embodiment 2

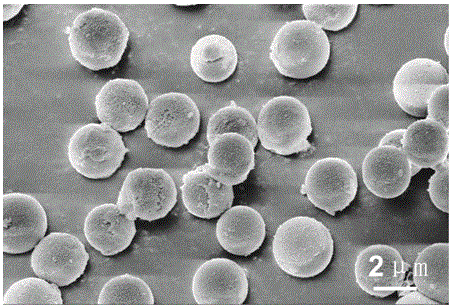

[0047] Take 0.1 g of solid silica gel microspheres in Example 1 and disperse them into 40 mL of deionized water for ultrasonic dispersion, then mix 0.74 g of cetyltrimethylammonium bromide (CTAB) and 0.46 g of trioctylmethylammonium bromide (TOMAB ) template agent dispersed in 80 mL of ethanol and water mixture (V 水 :V 乙醇 =1:1), ultrasonically dispersed evenly, then added to the silicon nucleus suspension, stirred for 30 min, then added dropwise 1 mL of ammonia water (25 wt%), stirred at room temperature for 30 min, and added dropwise 20 at a rate of 0.2 mL / min mL of TEOS solution (1-5% ethanol solution), react at room temperature for 6 h after the dropwise addition. After the reaction, the obtained product was repeatedly washed with deionized water and ethanol. Finally, the obtained product was dried at 60 °C for 6 h, and then the obtained product was put into a muffle furnace and calcined at 600 °C for 10 h. The obtained core-shell microspheres had an average pore size of...

Embodiment 3

[0050] Take 0.1 g of solid silica gel microspheres in Example 1 and disperse them into 40 mL of deionized water for ultrasonic dispersion, then mix 0.54 g of cetyltrimethylammonium bromide (CTAB) and 0.66 g of trioctylmethylammonium bromide (TOMAB ) template agent dispersed in 80 mL of ethanol and water mixture (V 水 :V 乙醇 =1:1), ultrasonically dispersed evenly, then added to the silicon nucleus suspension, stirred for 30 min, then added dropwise 1 mL of ammonia water (25 wt%), stirred at room temperature for 30 min, and added dropwise 20 at a rate of 0.2 mL / min mL of TEOS solution (1-5% ethanol solution), react at room temperature for 6 h after the dropwise addition. After the reaction, the obtained product was repeatedly washed with deionized water and ethanol. Finally, the obtained product was dried at 60 °C for 6 h, and then the obtained product was put into a muffle furnace and calcined at 600 °C for 10 h. The average pore diameter is 6.37 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com