Preparation method of like garnet structural ceramic reinforced aluminum/copper base high-damping composite material

A composite material, garnet technology, applied in the field of production of garnet-like structure ceramic reinforced Al/Cu-based high-damping composite materials, can solve the problems of poor bonding between metal matrix and ceramic interface, low fracture toughness, etc., and achieve enhanced damping Performance and mechanical properties, no mold cost, excellent shock and noise reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

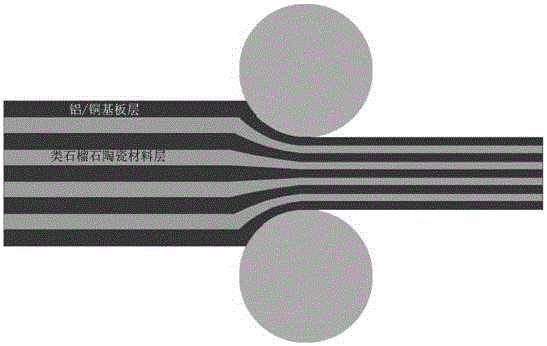

Embodiment 1

[0033] This embodiment provides a method for preparing a garnet-like structure ceramic reinforced Al / Cu-based composite material, including the following steps:

[0034] Step 1: Using pure Al or pure Cu or aluminum alloy or copper alloy as the substrate, ultrasonically clean the surface of the substrate, then polish the surface, remove the surface metal oxide, and obtain the metal substrate to be processed;

[0035] Step 2: Li with garnet-like structure 7+δ (La 3-x A x )(Zr 2-y m y )O 12 (LLAZMO) ceramic particles are ultrasonically dispersed in deionized water, and then uniformly precipitated on the surface of the metal substrate in step 1 to obtain a composite substrate; where A represents the doping element at the lanthanum position, which is barium (Ba) or calcium (Ca) or potassium (K) or strontium (Sr) or one of the rare earth elements, x is 0-1.25, M represents the zirconium doping element, which is indium (In) or vanadium (V) or tantalum (Ta) or niobium (Nb) Or on...

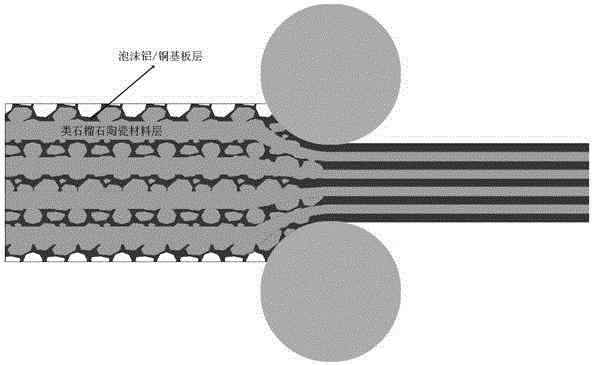

Embodiment 2

[0039] A method for preparing a garnet-like structure ceramic reinforced Al / Cu-based composite material provided in this embodiment includes the following steps:

[0040] Step 1: Using aluminum alloy foam or copper alloy foam plate as the substrate, ultrasonically clean the surface of the substrate, and then polish the surface to remove the metal oxide on the surface to obtain the metal substrate to be processed;

[0041] Step 2: Li with garnet-like structure 7+δ (La 3-x A x )(Zr 2-y m y )O 12 (hereinafter referred to as LLAZMO) ceramic particles are dispersed in ethanol, and the ethanol can also be replaced by other low-boiling alcohol reagents such as ethylene glycol or acetone, and then uniformly precipitated on the surface of the metal substrate in step (1) to obtain a composite substrate; Among them, A represents the doping element at the lanthanum position, which is one of barium (Ba) or calcium (Ca) or potassium (K) or strontium (Sr) or rare earth elements, x is 0-...

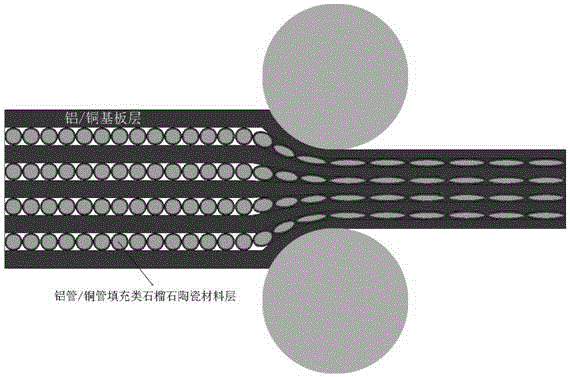

Embodiment 3

[0045] A method for preparing a garnet-like structure ceramic reinforced Al / Cu-based composite material provided in this embodiment includes the following steps:

[0046] Step 1: Use pure Al or pure Cu or aluminum alloy or copper alloy as the substrate, treat the surface of the substrate, remove the surface metal oxide, and obtain the metal substrate to be processed, and at the same time, take pure Al or pure Cu or aluminum alloy or copper Alloyed aluminum or copper tubes, surface treated to remove metal oxides;

[0047] Step 2: Li with garnet-like structure 7+δ (La 3-x A x )(Zr 2-y m y )O 12 After the ceramic particles are ultrasonically cleaned and dried, they are filled into the aluminum tube or copper tube in step 1. After the filling is completed, the surface of the metal tube is polished to remove excess metal oxides; the mass ratio of the metal tube to the ceramic particles is controlled so that the obtained composite base tube The mass percentage of ceramic parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com