Fermented feed for sows and piggies, and preparation method of fermented feed, as well as compound feed of fermented feed

A fermented feed and piglet technology, applied in the field of livestock breeding, can solve the problems of food refusal, cumbersome and complicated operation, anorexia of sows, etc., and achieve the effects of preventing oxidative stress response, improving nutritional level, and enhancing digestion, absorption and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

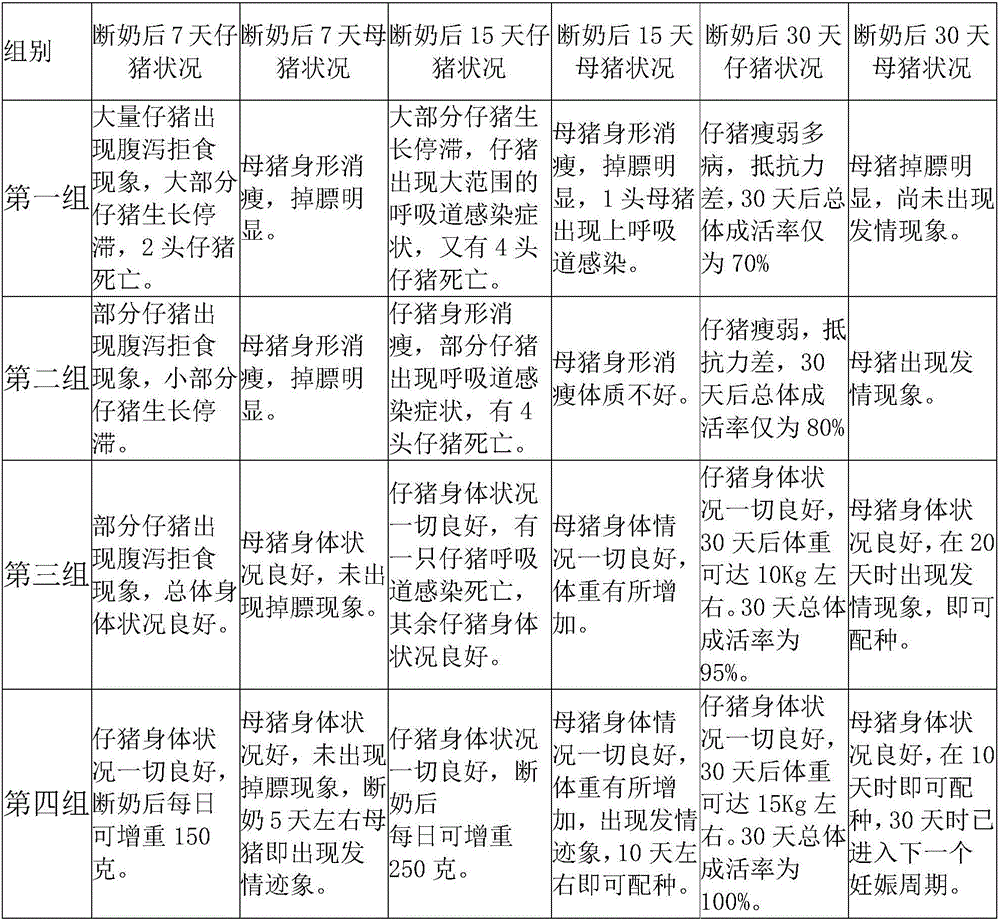

Examples

Embodiment 1

[0114] For the preparation of solid fermented material in fermented feed for sows and piglets, the raw materials are weighed according to the following parts by weight: 10 parts of astragalus extract, 2 parts of N-carbamylglutamic acid, 10 parts of egg powder, 200 parts of soybean meal, 50 parts of imported fish meal , 20 parts of brown sugar, 10 parts of whey powder, 10 parts of soybean oil, 5 parts of lysine, 2 parts of tryptophan, 2 parts of valine, 5 parts of threonine, 0.1 part of β-carotene, L- 0.5 part of carnitine, 0.1 part of porphyrin iron complex, 0.1 part of acid protease, 0.1 part of neutral protease, 0.1 part of chitosan oligosaccharide, 0.1 part of yeast selenium, 0.2 part of zinc methionine, 1 part of compound multivitamin, compound inorganic multivitamin 5 parts of minerals, 5 parts of sodium chloride, 10 parts of stone powder, 10 parts of calcium hydrogen phosphate and 10 parts of raw gypsum powder.

[0115] Then the raw materials are mixed to obtain solid fe...

Embodiment 2

[0117] For the preparation of solid fermented material in fermented feed for sows and piglets, the raw materials are weighed according to the following parts by weight: 100 parts of astragalus extract, 10 parts of N-carbamylglutamic acid, 100 parts of egg powder, 600 parts of soybean meal, 200 parts of imported fish meal ,, 80 parts of brown sugar, 100 parts of whey powder, 50 parts of soybean oil, 50 parts of lysine, 20 parts of tryptophan, 20 parts of valine, 20 parts of threonine, 1 part of β-carotene, L - 5 parts of carnitine, 5 parts of porphyrin iron complex, 1 part of acid protease, 1 part of neutral protease, 1 part of chitosan oligosaccharide, 1 part of yeast selenium, 2 parts of zinc methionine, 5 parts of compound multivitamins, compound inorganic 10 parts of various minerals, 15 parts of sodium chloride, 30 parts of stone powder, 30 parts of calcium hydrogen phosphate and 30 parts of raw gypsum powder.

[0118] Then the raw materials are mixed to obtain solid ferme...

Embodiment 3

[0120] For the preparation of solid fermented material in fermented feed for sows and piglets, the raw materials are weighed according to the following parts by weight: 20 parts of astragalus extract, 8 parts of N-carbamylglutamic acid, 40 parts of egg powder, 300 parts of soybean meal, and 140 parts of imported fish meal ,, 60 parts of brown sugar, 40 parts of whey powder, 20 parts of soybean oil, 40 parts of lysine, 6 parts of tryptophan, 11 parts of valine, 12 parts of threonine, 0.3 parts of β-carotene, L - 0.6 parts of carnitine, 4 parts of porphyrin iron complex, 0.7 parts of acid protease, 0.3 parts of neutral protease, 0.4 parts of chitosan oligosaccharide, 0.6 parts of yeast selenium, 0.7 parts of zinc methionine, 3 parts of compound multivitamins, compound inorganic 6 parts of various minerals, 14 parts of sodium chloride, 11 parts of stone powder, 11 parts of calcium hydrogen phosphate and 11 parts of raw gypsum powder.

[0121] Then the raw materials are mixed to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com