Preparation method of composite nano-filtration membrane with self-repairing, bacterium-resisting and solvent-resisting functions

A nanofiltration membrane and solvent-resistant technology, which is applied in the field of preparation of composite nanofiltration membranes, can solve the problems of increasing membrane separation use and operating costs, reducing separation efficiency and service life, and achieving increased added value and economic value, and the number of layers less, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

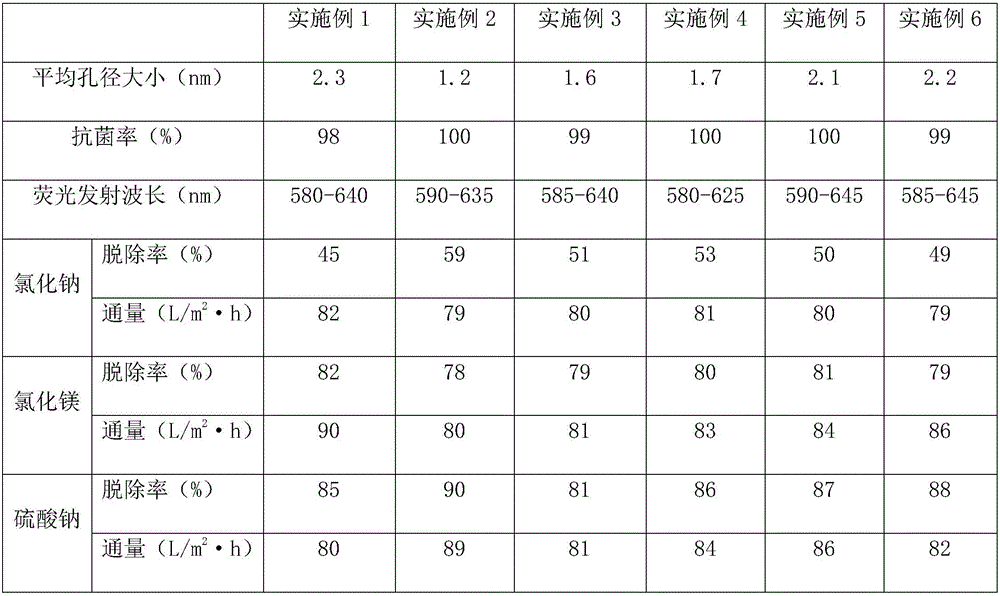

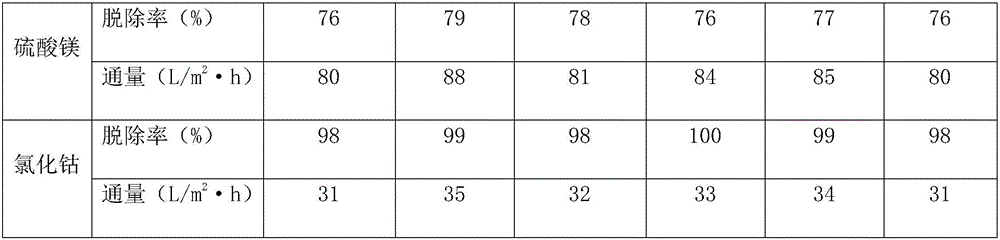

Embodiment 1

[0030] (1) Add ε-polylysine cationic polyelectrolyte into deionized water, fully stir, add sodium chloride, stir evenly, obtain the cationic polyelectrolyte solution that mass fraction is 0.1%, wherein the concentration of sodium chloride is 0.5M, The pH value is 2.5.

[0031] (2) The zinc ion of 1mmol / L and the transition metal ion solution of europium ion and the bisleidyl oxalic acid solution of 1mmol / L are mixed, wherein all contain the sodium chloride of 5mmol / L in the transition metal ion solution and the bisleidyl oxalic acid solution , the pH value of the mixed system is adjusted to 5.5 with a buffer, and it is fully stirred to obtain a supramolecular polymer solution with a mass fraction of 0.1%, wherein the molar ratio of transition metal ions and bisleidyl oxalic acid in the supramolecular polymer solution is 1:1 .

[0032] (3) The alkali-modified polyacrylonitrile ultrafiltration membrane with a molecular weight cut-off of 50,000 is used as a base membrane, fixed ...

Embodiment 2

[0037] (1) Add chitosan cationic polyelectrolyte to deionized water, fully stir, add sodium chloride, stir evenly, obtain the cationic polyelectrolyte solution that mass fraction is 0.4%, wherein the concentration of sodium chloride is 0.5M, pH value is 3.

[0038] (2) the cobalt ion of 5mmol / L and the bisleidyl oxalic acid solution of iron ion transition metal ion solution and 5mmol / L are mixed, wherein all contain the sodium chloride of 5mmol / L in the transition metal ion solution and the bisleidyl oxalic acid solution , adjust the pH value of the mixed system to 6.5 with a buffer, stir well to obtain a supramolecular polymer solution with a mass fraction of 0.4%, wherein the molar ratio of transition metal ions and bisleidyl oxalic acid in the supramolecular polymer solution is 1:2 .

[0039] (3) The sulfonated polyethersulfone ultrafiltration membrane with a molecular weight cut-off of 30,000 is used as a base membrane, and is fixed in a container with a porous support la...

Embodiment 3

[0044] (1) ε-polylysine cationic polyelectrolyte is added to deionized water, fully stirred, sodium chloride is added, stirred evenly, and the cationic polyelectrolyte solution that obtains mass fraction is 0.2%, wherein the concentration of sodium chloride is 0.5M, The pH is 2.7.

[0045] (2) the zinc ion of 2mmol / L and the lanthanum ion transition metal ion solution and the bisleidyl oxalic acid solution of 3mmol / L are mixed, wherein all contain the sodium chloride of 5mmol / L in the transition metal ion solution and bisleidyl oxalic acid solution , adjust the pH value of the mixed system to 5.8 with a buffer, stir well to obtain a supramolecular polymer solution with a mass fraction of 0.2%, wherein the molar ratio of transition metal ions and bisleidyl oxalic acid in the supramolecular polymer solution is 1:1.5 .

[0046] (3) A cellulose acetate hollow fiber membrane with a molecular weight cut-off of 50,000 is used as a base membrane, and fixed in a container with a porou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com