Synthesis method of magnetic phosphorus adsorbent based on lanthanum loaded fly ash beads

A synthesis method, phosphorus adsorbent technology, applied in chemical instruments and methods, adsorption water/sewage treatment, silicon compounds, etc., can solve the problems of phosphorus removal, precipitation, and low efficiency of phosphorus removal in wastewater, and achieve good application prospects , simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment prepares lanthanum-loaded fly ash magnetic beads according to the following steps:

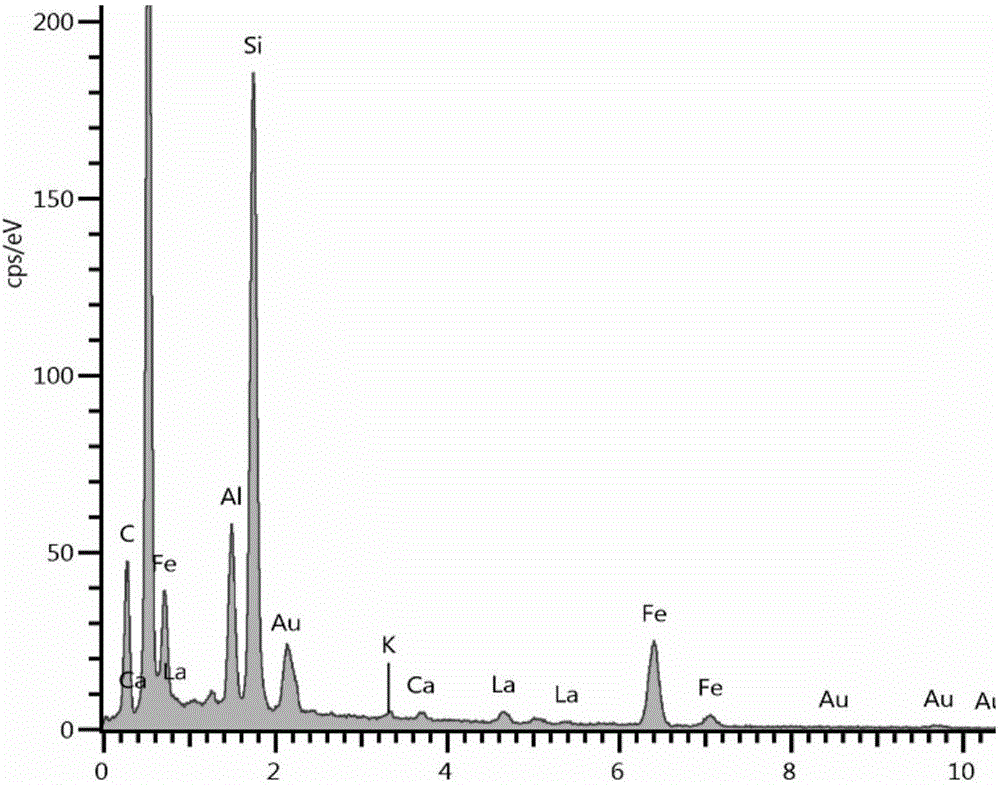

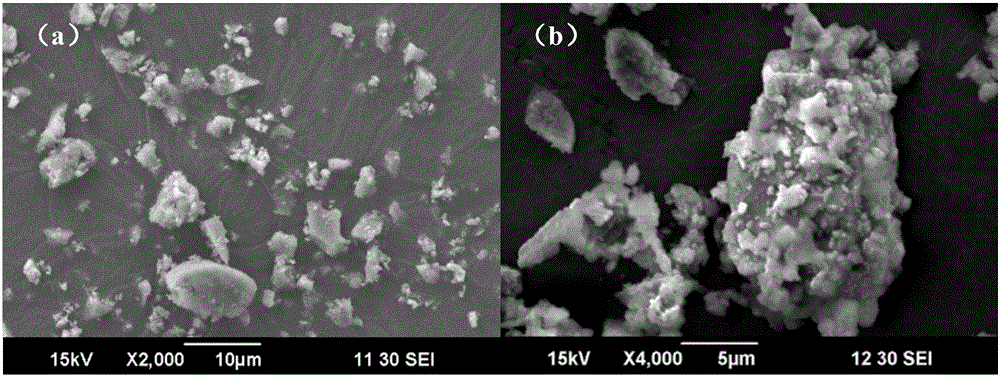

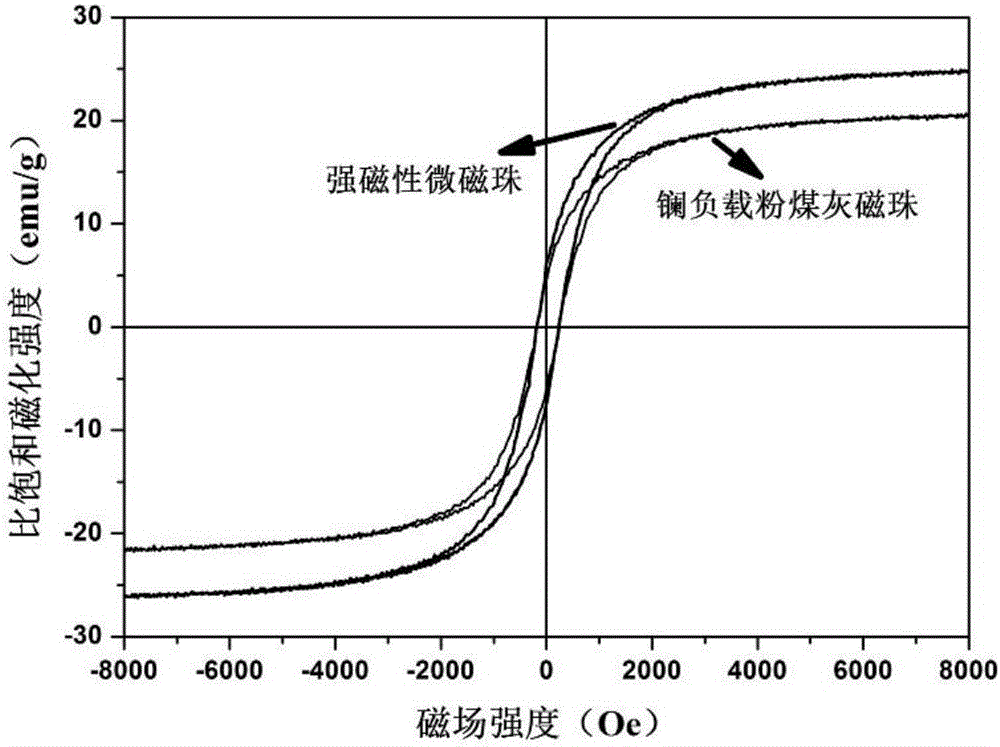

[0027] 1) Through sieving, magnetic separation, ball milling and re-magnetic separation and other processes, obtain strong magnetic micro-magnetic beads with an average particle size of 4.6 μm, a specific saturation magnetization of 26.44emu / g, and an iron grade of 56.1%. Set aside to dry.

[0028] 2) Put 3 g of strong magnetic micro-magnetic beads in a beaker, add 100 mL of water, 400 mL of absolute ethanol and 25 mL of ammonia water with a mass concentration of 28%, and stir for 10 minutes to fully infiltrate and suspend the strong magnetic micro-magnetic beads state. 1.63 mL of tetraethyl orthosilicate with a mass concentration of 98.6% was added dropwise at a speed of 0.5 mL / min, and then electric stirring was performed at a speed of 500 r / min for 6 hours. Finally, solid-liquid separation is assisted by a strong NdFeB magnet, washed once with ethanol and water, and...

Embodiment 2

[0035] Using the lanthanum-loaded fly ash magnetic beads obtained in Example 1 to treat simulated phosphorus-containing wastewater, the maximum saturated phosphorus adsorption capacity of the lanthanum-loaded fly ash magnetic beads is 18.359 mg / g, compared with the strong magnetic micro-magnetic beads The adsorption capacity has increased by 258.8%. Systematic orthogonal experiments show that the saturated phosphorus adsorption capacity of lanthanum-loaded fly ash magnetic beads increases with the decrease of pH, and is close to the maximum value near pH=4.0; with the increase of temperature, the phosphorus adsorption capacity increases slightly. At the same temperature, the adsorption capacity of lanthanum-loaded fly ash magnetic beads did not change much for different concentrations of phosphorus-containing wastewater.

[0036] Studies have shown that the adsorption of lanthanum-loaded fly ash magnetic beads can be divided into three stages. In the first stage of 0-10 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com