Organic compound fertilizer

A compound fertilizer and organic technology, applied in the field of organic compound fertilizers, can solve the problems of producing a large amount of harmful gases, land nitrogen pollution, soil unfavorable, etc., so as to reduce land nitrogen pollution, avoid complex processes, and achieve good application effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

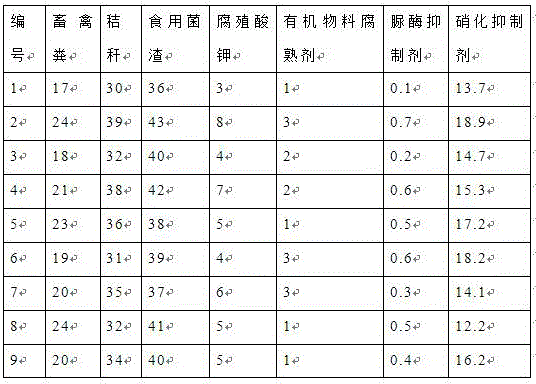

[0042] Take 17-24 parts by mass of livestock and poultry manure, 30-39 parts of straw, 36-43 parts of edible fungus residue, 3-8 parts of potassium humate and 1-3 parts of organic material decomposing agent as materials for fermentation. Slowly dry the edible fungus residue in an oven at 38°C until the water content is ≤27%, then stop drying; the dried edible fungus residue is placed under vacuum conditions, and nitrogen is introduced until the air pressure is 1.4~1.7MPa. Under the conditions, the current is 0.10A, and the current density is 1.8mA / cm 2 , electrostatically treated for 8~10s; air was introduced to normal pressure, and the temperature was raised to 35°C for 17~24h. Organic material decomposing agent Mix the organic material decomposing agent and soil evenly according to the mass ratio of 1:1, adjust the water content to 37-42%, adjust the pH of the system to 7.3-7.8, and place it in a ventilated place at room temperature for 10-25 minutes; put the soil mixture in...

Embodiment 2

[0047] Add measured polyacrylamide into a three-neck flask with stirring, thermometer and vacuum device, stir and heat, vacuum degree 0.098MPa, dehydration at 110°C for 2h, cool down to about 40°C, add toluene diisocyanate, in (80± 2) After heating and reacting at a temperature of ℃ for 2~3h, vacuum degassing and cooling down to room temperature to obtain a coating; take an appropriate amount of organic compound fertilizer, and spray the coating at a spraying speed of 0.4~0.6kg / h through an independent spray system Spray the compound and diethyltoluenediamine components on the surface of the boiling fertilizer particles respectively, so that the two components react on the surface of the fertilizer particles and solidify to form a film; when spraying, the atomization pressure of the nozzle is 0.7~1.2MPa, and the The wind temperature is 20~40℃, and the fertilizer temperature is 30~35℃.

Embodiment 3

[0049] Potassium humate is prepared by the following steps: Dissolve humic acid powder in an appropriate amount of deionized water and heat to 60°C, add 0.1mol / mL sodium hydroxide solution dropwise to pH 9~9.8, according to humic acid Add potassium nitrate and tetrabutyl titanate to the solution at a molar ratio of 1:1.2:0.3, keep a constant temperature of 60°C, and irradiate the reaction system with a UV lamp with a power of 15W as the light source. After reacting for 4 to 5 hours, cool naturally Afterwards, it was aged at room temperature, and after the solvent was evaporated to dryness by a rotary evaporator, the product was dried in an oven at 96° C. and ground to powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com