Self-repairing enhanced polyarylether composite material and preparation method thereof

A technology of composite material and polyarylether, which is applied in the field of self-repairing enhanced polyarylether composite material and its preparation, can solve problems such as difficulties and achieve excellent mechanical properties, prolong service life and high melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

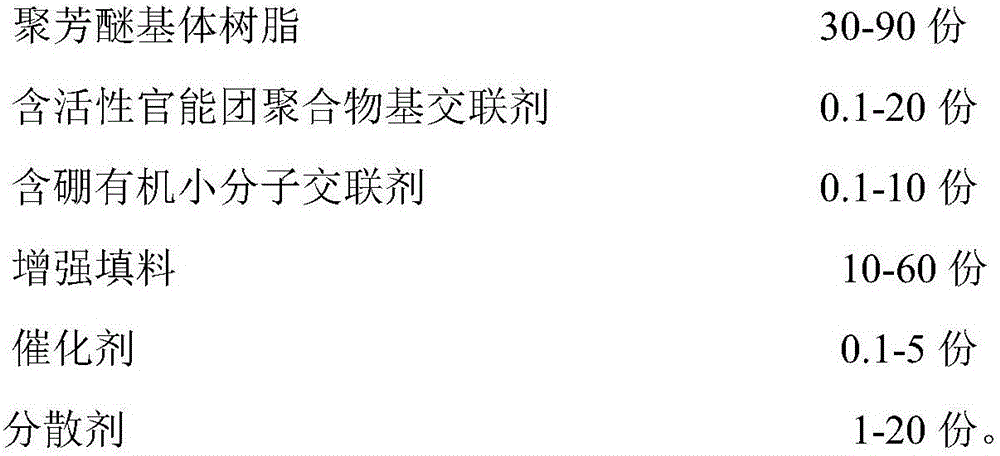

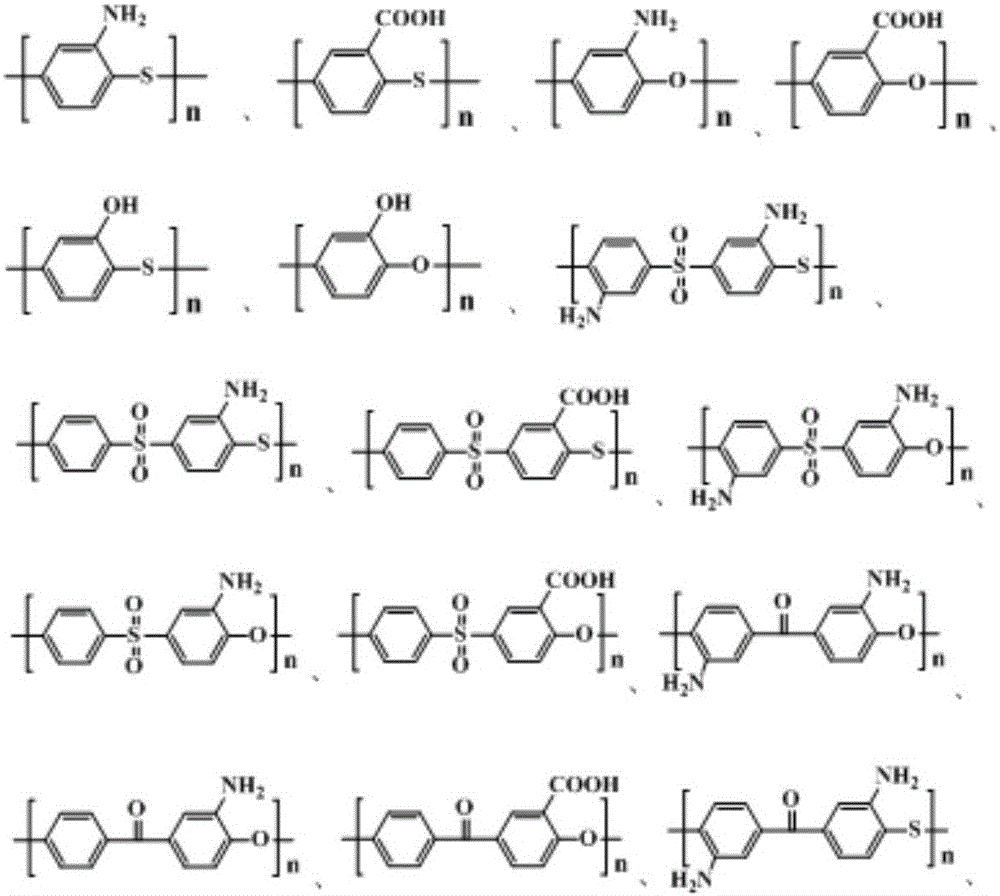

Method used

Image

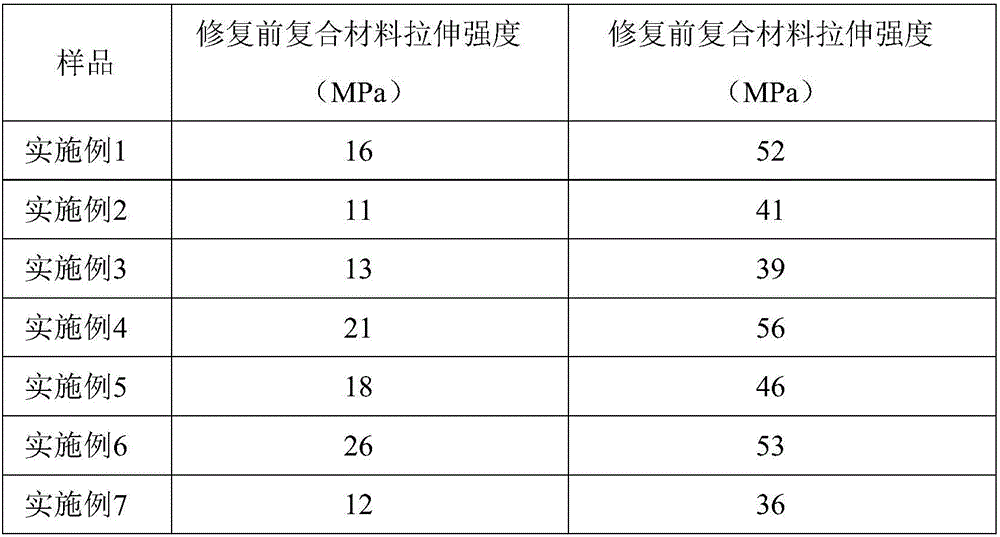

Examples

Embodiment 1

[0027] (1) Dissolve 5g of p-aminophenylboronic acid in 10g of ethanol to make a uniform mixed solution, then add this mixed solution, 90g of polyethersulfone resin, 20g of carboxyl-containing polyethersulfone and 1g of triphenyl phosphite to the high-speed In a mixer, mix at room temperature for 10 minutes to obtain a mixed masterbatch;

[0028] (2) Dry the uniformly dispersed mixed masterbatch at a temperature of 50°C and a vacuum of 0.05MPa for 6 hours to obtain a dried mixed masterbatch; then add the masterbatch from the main feeding port of the twin-screw extruder , set the screw speed at 50rpm, and the temperature at 330°C; at the same time, add 60g of glass fiber from the side feeding port of the twin-screw extruder, melt and blend for 2min, extrude, cool, granulate, and dry to obtain self-repairing reinforcement type polyaryl ether sulfone composite material; it was injection molded into a standard tensile spline, and a gap with a width of 0.1mm and a depth of 1mm was c...

Embodiment 2

[0030] (1), 10g of p-carboxyphenylboronic acid was dissolved in 20g of acetone to make a uniform mixed solution, and then the mixed solution was mixed with 30g of polyphenylene sulfide resin, 5g of amino-containing polyphenylene sulfide, and 0.1g of trimethyl chloride Add silicon oxide into the high-speed mixer together, and mix for 1 min at room temperature to obtain a mixed masterbatch;

[0031] (2) Dry the uniformly dispersed mixed masterbatch at a temperature of 30°C and a vacuum of 0.085MPa for 1 hour to obtain a dried mixed masterbatch; then add the masterbatch from the main feeding port of the twin-screw extruder , set the screw speed at 200rpm, and the temperature at 290°C; at the same time, add 10g of carbon fiber from the side feeding port of the twin-screw extruder, melt and blend for 10min, extrude, cool, granulate, and dry to obtain a self-repairing enhanced type Polyphenylene sulfide composite material; inject it into a standard tensile spline, and cut a gap with...

Embodiment 3

[0033] (1), 0.1g of p-hydroxyphenylboronic acid was dissolved in 1g of ethyl formate to form a uniform mixed solution, and then this mixed solution was mixed with 40g of polyphenylene sulfide resin, 2g of carboxyl-containing polyphenylene ether, and 5g of stannous octoate. and added to a high-speed mixer, and mixed for 6 minutes at room temperature to obtain a mixed masterbatch;

[0034] (2) Dry the uniformly dispersed mixed masterbatch at a temperature of 80°C and a vacuum of 0.095MPa for 1 hour to obtain a dried mixed masterbatch; then add the masterbatch from the main feeding port of the twin-screw extruder , set the screw speed at 120rpm, and the temperature at 300°C; at the same time, add 40g of aramid 1414 fiber from the side feeding port of the twin-screw extruder, melt and blend for 4min, extrude, cool, granulate, and dry to obtain the self- Repair the reinforced polyarylether composite material; inject it into a standard tensile spline, and cut a gap with a width of 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average tensile strength | aaaaa | aaaaa |

| Average tensile strength | aaaaa | aaaaa |

| Average tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com