C3N4-Bi2O3-BiOI-TiO2NTs visible-light response photocatalysis electrode as well as preparation method and application thereof

A photocatalytic and visible light technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc., can solve problems such as difficult treatment and secondary pollution, and achieve the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

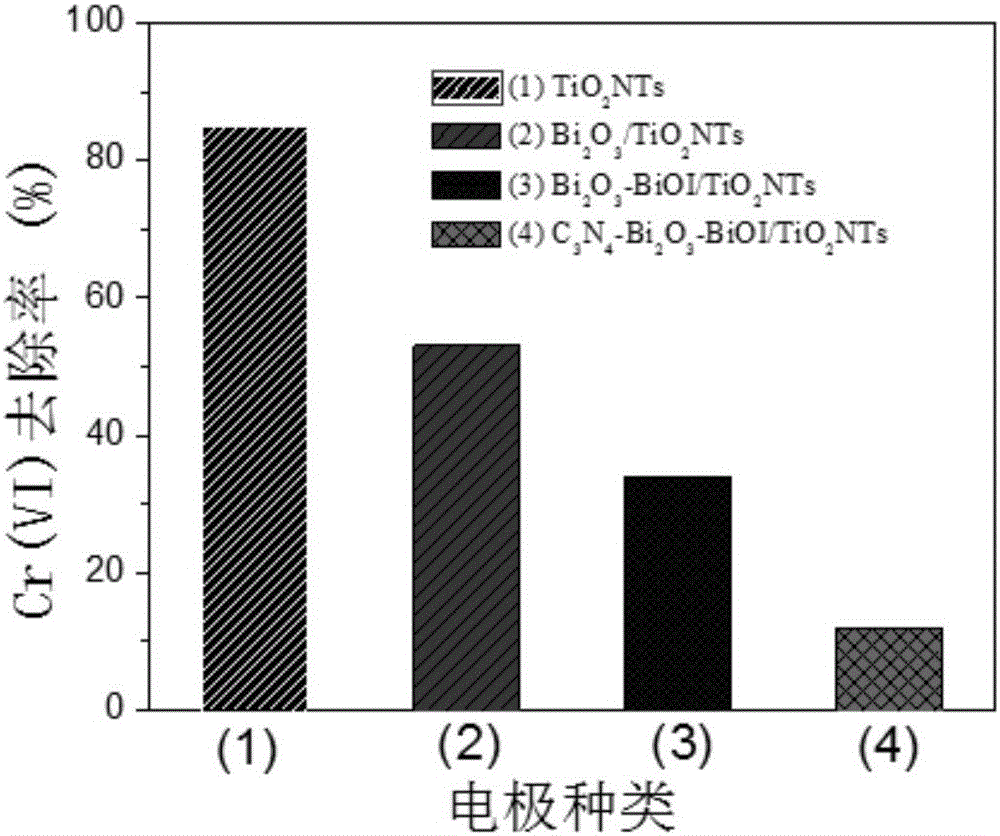

[0064] TiO 2 Nanotube Array Electrode, C 3 N 4 -Bi 2 o 3 / TiO 2 Nanotube array electrodes and C 3 N 4 -Bi 2 o 3 -BiOI / TiO 2The nanotube array electrode was tested for the reduction kinetics of Cr(VI). In a reactor equipped with a working electrode and a Ti sheet as a counter electrode, chromium-containing wastewater containing 1ml of a hole-trapping agent was added, and the pH value was adjusted to 3 , after stirring and adsorption equilibrium in the dark, apply voltage, turn on the light source, and carry out the reaction, and the reaction lasts for 160 minutes.

[0065] The photocatalytic degradation effects of different types of nanotube array electrodes under visible light conditions are as follows: figure 1 shown. To verify C 3 N 4 -Bi 2 o 3 -BiOI / TiO 2 Ternary composite catalytic electrode compared with the original substrate TiO 2 The photocatalytic performance of the nanotube array electrode has been significantly improved, from figure 1 From the data...

Embodiment 2

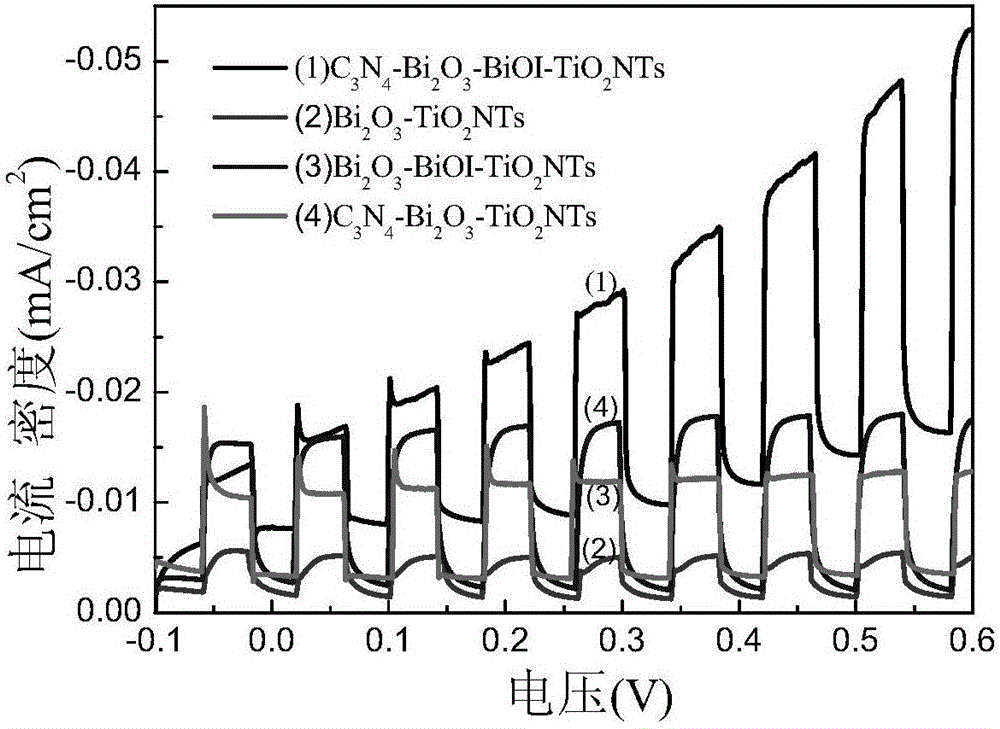

[0067] Determination of C by electrochemical workstation 3 N 4 -Bi 2 o 3 -BiOI / TiO 2 The photochemical performance test of the nanotube electrode, firstly with the prepared C 3 N 4 -Bi 2 o 3 -BiOI / TiO 2 The nanotube electrode is the working electrode, the Pt sheet is the counter electrode, the Ag / AgCl is the reference electrode, and the Na 2 SO 4 (0.1mol / L) and Na 2 SO 3 (0.1mol / L) solution is the electrolyte. by C 3 N 4 -Bi 2 o 3 -BiOI / TiO 2 The nanotube electrode was scanned to obtain the volt-ampere curve. The light source in this experiment was a xenon lamp (500W). Under the condition that the positions of the electrodes and the light source were consistent, scanning of visible light was carried out respectively. and with C 3 N 4 -Bi 2 o 3 / TiO 2 Nanotube electrode, Bi 2 o 3 / TiO 2 Nanotube electrodes, TiO 2 The photocurrents of nanotube electrodes under visible light and ultraviolet light were compared.

[0068] From figure 2 It can be seen th...

Embodiment 3

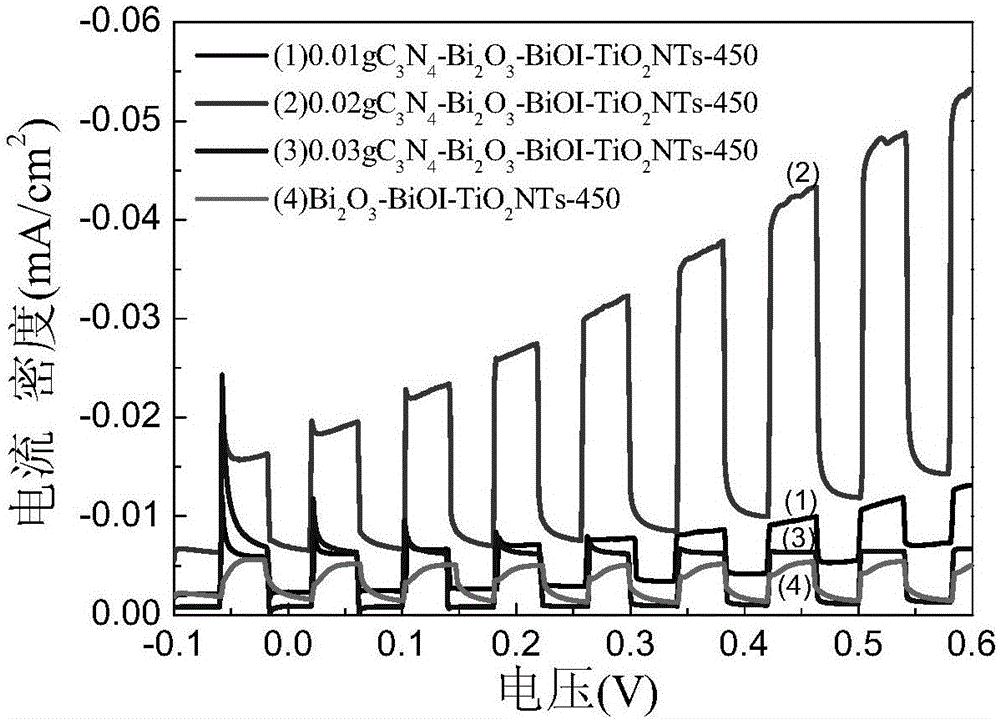

[0070] Change g-C in preparation steps (4) and (5) 3 N 4 The amount added to prepare the resulting different g-C 3 N 4 Added amount of C 3 N 4 -Bi 2 o 3 -BiOI / TiO 2 The nanotube electrode is the working electrode, the Pt sheet is the counter electrode, the Ag / AgCl is the reference electrode, and the Na 2 SO 4 (0.1mol / L) and Na 2 SO 3 (0.1mol / L) solution is the electrolyte. by C 3 N 4 -Bi 2 o 3 -BiOI / TiO 2 The nanotube electrode was scanned to obtain the volt-ampere curve. The light source in this experiment was a xenon lamp (500W). Under the condition that the positions of the electrodes and the light source were consistent, the visible light scans were carried out respectively. The results are as follows: image 3 shown. From image 3 It can be seen from the data that when adding different masses of g-C 3 N 4 Next, the prepared C 3 N 4 -Bi 2 o 3 -BiOI / TiO 2 The photocurrent difference of the nanotube array electrode is more obvious, when adding 0.02g ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com