Separation and purification method of glycerine and iminodiacetic acid

A technology of iminodiacetic acid and iminodiacetic acid salt, which is applied in the field of separation and purification of glycine and iminodiacetic acid, can solve the problems of long reaction route, low-value waste water residue, and large loss of glycine, etc., and achieves simple operation, The effect of high selectivity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

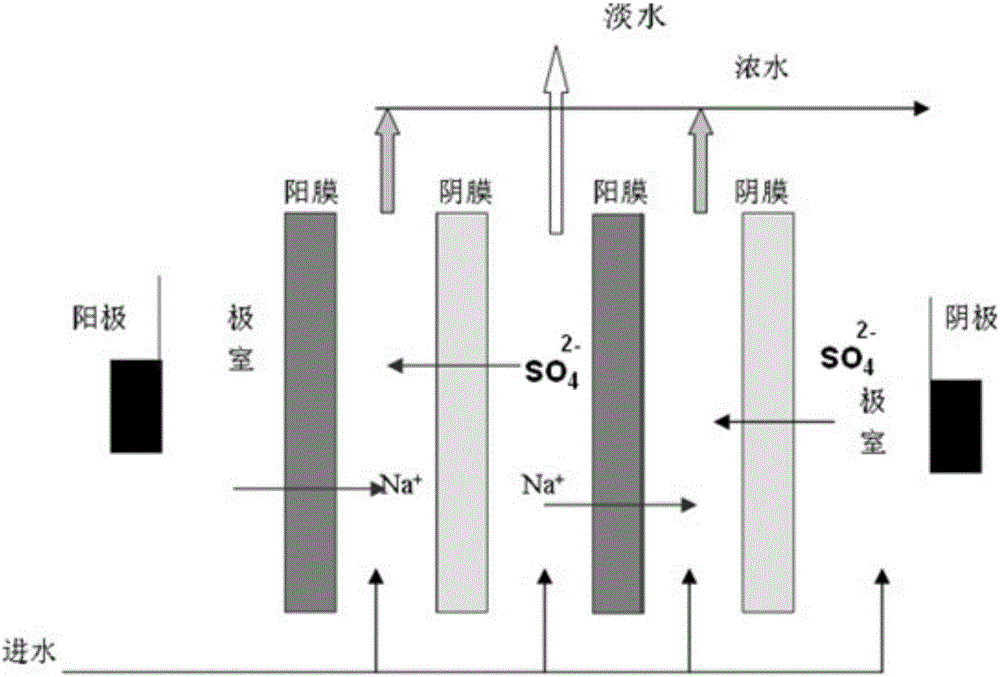

Method used

Image

Examples

Embodiment 1

[0028] Weigh 1425 grams of 40% hydroxyacetonitrile (10.0 mol) and 708.3 grams of 60% ammonia (25 mol) and mix them into the tubular reactor. The reaction temperature is controlled at 70°C-80°C and the reaction pressure is 1.2-1.5MPa, the retention time of the material in the tubular reactor is 15 minutes, the outlet of the tubular reactor is directly connected to the hydrolysis reactor, and 1200 grams of 40% sodium hydroxide aqueous solution (12mol) is added to the hydrolysis reactor. , The temperature is raised to 70°C; the ammoniated liquid of aminoacetonitrile and iminodiacetonitrile flowing out of the outlet of the tubular reactor is directly added to the aqueous sodium hydroxide solution, and the ammoniated liquid is removed under the condition of maintaining a slight negative pressure during the hydrolysis of the ammoniated liquid After 15 minutes, the temperature was raised to 100°C and kept for 3 hours to obtain an aqueous solution of sodium glycinate and disodium iminod...

Embodiment 2

[0032] Weigh 1140 grams of 50% hydroxyacetonitrile (10.0 mol) and 566.7 grams of 60% ammonia (20 mol) and mix them into the tubular reactor. The reaction temperature is controlled at 70°C-80°C and the reaction pressure is 1.0-1.2MPa, the retention time of the material in the tubular reactor is 15 minutes, the outlet of the tubular reactor is directly connected to the hydrolysis reactor, and 1200 grams of 40% sodium hydroxide aqueous solution (12mol) is added to the hydrolysis reactor. , The temperature is raised to 70°C; the ammoniated liquid of aminoacetonitrile and iminodiacetonitrile flowing out of the outlet of the tubular reactor is directly added to the aqueous sodium hydroxide solution, and the ammoniated liquid is removed under the condition of maintaining a slight negative pressure during the hydrolysis of the ammoniated liquid After 15 minutes, the temperature was raised to 100°C and kept for 3 hours to obtain an aqueous solution of sodium glycinate and disodium iminod...

Embodiment 3

[0036] Weigh 1425 grams of 40% hydroxyacetonitrile (10.0 mol), then add 425 grams of ammonia gas (25 mol) and mix them into the tubular reactor. The reaction temperature is controlled at 70°C-80°C and the reaction pressure is 1.5 -1.8MPa, the retention time of the material in the tubular reactor is 10 minutes, the outlet of the tubular reactor is directly connected to the hydrolysis reactor, and 1760 grams of 25% sodium hydroxide aqueous solution (11mol) and sodium hydroxide are added to the hydrolysis reactor The aqueous solution is first heated to 70°C; the ammoniated liquid of aminoacetonitrile and iminodiacetonitrile from the outlet of the tubular reactor is directly added to the aqueous sodium hydroxide solution, and the ammoniated liquid is removed under the condition of maintaining a slight negative pressure during the hydrolysis of the ammoniated liquid After 10 minutes, the temperature was raised to 100°C and the temperature was kept for 2.5 hours to obtain an aqueous s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com