Ecological slow release fertilizer special for wheat and preparation method thereof

A slow-release fertilizer, wheat technology, applied in the application, nitrogen fertilizer, potassium fertilizer and other directions, can solve the problems of difficult degradation of coated materials, limited large-scale use, and expensive coated fertilizers, so as to facilitate absorption, improve soil nutrient status, avoid Premature aging and de-fat effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

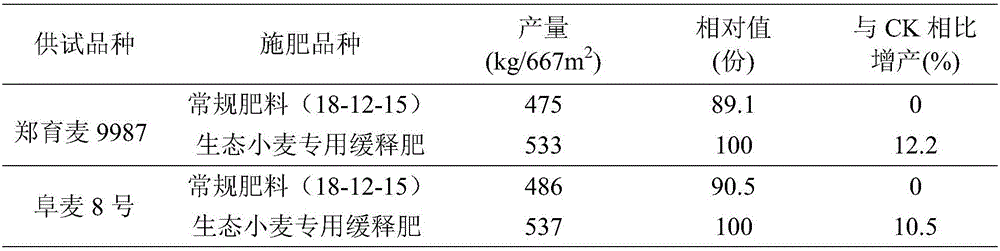

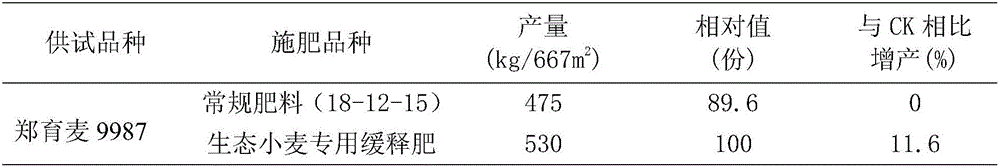

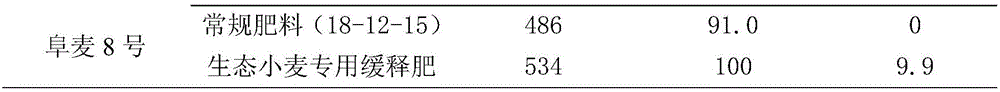

Examples

Embodiment 1

[0026] In the present embodiment, a special slow-release fertilizer for ecological wheat comprises the following raw materials by weight percentage: urea 13%, monoammonium phosphate 35%, potassium chloride 17%, ammonium phosphorus 8%, phosphoric acid 1%, liquid ammonia 5% %, concentrated sulfuric acid 1%, lignite 10%, nitro humic acid 1%, modified cassava flour 4%, amino acid chelated zinc 0.5%, zinc sulfate 1%, borax 0.5%, ferrous sulfate 0.5%, manganese sulfate 1%, ammonium molybdate 0.3%, fertilizer synergist 0.2%, zeolite powder 1%;

[0027]Wherein, the preparation method of the modified cassava flour comprises: adding water to the cassava flour and raising the temperature to 50°C, stirring until a paste is formed, adding ferrous sulfate and stirring evenly, and then adding hydrogen peroxide with a content of 32wt% dropwise, and the process is completed within 5 minutes Add dropwise, after stirring evenly, add a sodium hydroxide solution with a content of 35wt%, adjust the...

Embodiment 2

[0034] In the present embodiment, a special slow-release fertilizer for ecological wheat comprises the following raw materials by weight percentage: 15% urea, 28% monoammonium phosphate, 19% potassium chloride, 14% ammonium nitrate phosphorus, 2% phosphoric acid, 2% liquid ammonia %, concentrated sulfuric acid 1%, lignite 6%, nitro humic acid 1%, modified cassava flour 4%, amino acid chelated zinc 0.5%, zinc sulfate 0.5%, borax 1%, ferrous sulfate 0.3%, manganese sulfate 1%, ammonium molybdate 0.2%, fertilizer synergist 0.5%, perlite 4%;

[0035] Wherein, the preparation method of the modified cassava flour comprises: adding water to the cassava flour and raising the temperature to 55° C., stirring until a paste is formed, adding ferrous sulfate and stirring evenly, and then adding hydrogen peroxide with a content of 28 wt % dropwise, and the process is completed within 10 minutes. Add dropwise, stir evenly, add sodium hydroxide solution with a content of 30wt%, adjust the pH ...

Embodiment 3

[0043] In the present embodiment, a special slow-release fertilizer for ecological wheat comprises the following raw materials by weight percentage: urea 21%, monoammonium phosphate 35%, potassium chloride 17%, ammonium phosphorus 8%, phosphoric acid 1%, liquid ammonia 2% %, concentrated sulfuric acid 1%, lignite 6%, nitro humic acid 1%, modified cassava flour 4%, amino acid chelated zinc 0.5%, zinc sulfate 0.5%, borax 0.5%, ferrous sulfate 0.3%, manganese sulfate 1%, ammonium molybdate 0.1%, fertilizer synergist 0.1%, porous auxiliary material 1%;

[0044] Wherein, the preparation method of the modified cassava flour comprises: adding water to the cassava flour and raising the temperature to 52°C, stirring until a paste is formed, adding ferrous sulfate and stirring evenly, and then adding hydrogen peroxide with a content of 30wt% dropwise, and the process is completed within 7 minutes Add dropwise, after stirring evenly, add a sodium hydroxide solution with a content of 33wt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com