A preparation method of carbon-silicon solid acid catalyst and its application in extracting organic acids in fermentation broth

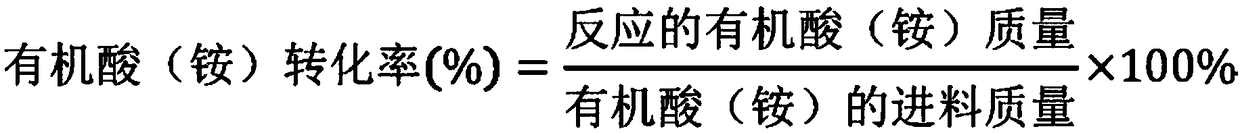

A solid acid catalyst and carbon silicon technology, which is applied in the preparation of organic compounds, carboxylate preparation, chemical instruments and methods, etc., can solve the problems of low extraction efficiency of low-concentration organic acids, so as to improve the sulfonation effect and reduce the extraction rate. Good effect of cost and reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of carbon-silicon solid acid catalyst: Dissolve 8 g of cornstarch in water at a solid-to-liquid ratio of 1:20, add 8 g of tetraethyl orthosilicate, co-hydrolyze for two hours under boiling conditions, and age at room temperature for 1-2 days. Exchange the water in the system with ethanol, filter and dry, disperse the obtained powder into the soluble chloride salt zinc chloride solution, dry and carbonize and activate at a temperature of 500°C for 4 hours, and wash away the zinc chloride in the material with hydrochloric acid; The obtained carbon-silicon material was sulfonated with concentrated sulfuric acid at 100° C. for 2 h at a solid-to-liquid mass ratio of 1:10, cooled to room temperature, filtered and washed, and dried to obtain a carbon-silicon material solid acid catalyst.

Embodiment 2

[0034] Except that the following steps are different, the others are the same as in Example 1, and the soluble soybean starch is dissolved in water at a solid-to-liquid ratio of 1:10 to prepare a carbon-silicon solid acid catalyst.

Embodiment 3

[0036] Except that the following steps are different, all the others are the same as in Example 1, and a total of 8 g of starch from soluble potato and wheat starch (mass ratio 1: 1) are dissolved in water to prepare a carbon-silicon solid acid catalyst at a solid-to-liquid ratio of 1: 30.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com