Water-based lubricating cutting fluid and preparation method thereof

A cutting fluid, water-based technology, applied in lubricating compositions, petroleum industry, additives, etc., to achieve good dispersibility, high graft density, and enhanced dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

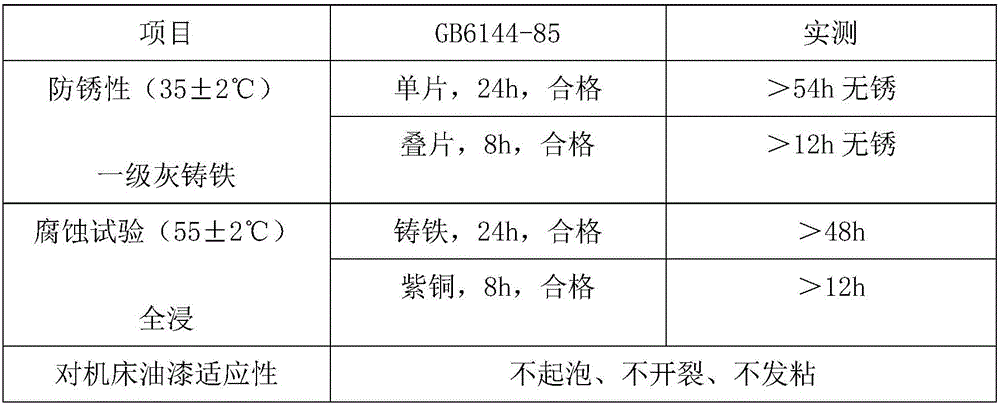

Image

Examples

Embodiment Construction

[0021] A water-based lubricating cutting fluid, which is made up of the following raw materials in parts by weight:

[0022] Ammonium polyphosphate 2, sodium diacetate 0.7, butyl benzyl phthalate 1, copper sulfate 0.2, styrene 10, maleic anhydride 3, benzoyl peroxide 0.1, nano silicon dioxide 5, propynyl alcohol 1, Sodium nitride 0.4, aluminum chloride 0.6, Span 802, silane coupling agent kh5600.7, sodium ascorbate 0.1, 2,3 dimethylaniline 0.6, sorbitan monooleate 3, benzyl triphenyl chloride Phosphine 1, stannous sulfate 0.6, sorbitol 2, formamide 0.6.

[0023] A preparation method of said water-based lubricating cutting fluid, comprising the following steps:

[0024] (1) Mix the above-mentioned sodium diacetate and maleic anhydride, add it to deionized water 7 times the weight of the mixture, stir evenly, add formamide, raise the temperature to 60°C, and keep stirring for 20 minutes to obtain an amide dispersion;

[0025] (2) Mix the above-mentioned styrene and benzoyl per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com