Steamed bread flour with hypoglycemic effect

A technology of steamed bread powder and flour, which is applied in the field of steamed bread processing, can solve the problem of hypoglycemic staple foods such as weakness, and achieve the effects of obvious hypoglycemic effect, soft taste and physical fitness enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

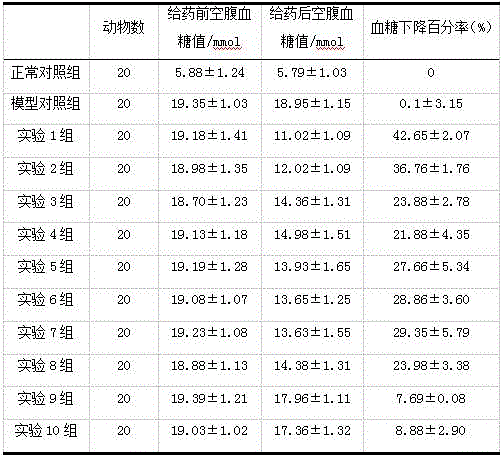

Examples

Embodiment 1

[0028] Crush the bean dregs to 150 meshes to obtain bean dregs powder;

[0029] Crush wheat bran to 150 meshes to obtain wheat bran powder;

[0030] Crush the peeled yam to 150 meshes to obtain the peeled yam powder;

[0031] Crush the yam with skin to 150 mesh to get yam with skin powder;

[0032] Crush the bean dregs to 20 meshes, extrude and puff them, and then crush them to more than 150 meshes to obtain puffed bean dregs powder;

[0033] Wheat bran is crushed to 20 mesh, then extruded and puffed, and then crushed to more than 150 mesh to obtain puffed wheat bran powder;

[0034] Crush the peeled yam to 20 mesh, then extrude and puff it, and then crush it to more than 150 mesh to obtain the peeled yam puffed powder;

[0035] Crush the yam with skin to 20 mesh, then extrude and puff it, and then crush it to more than 150 mesh to obtain puffed yam with skin powder;

[0036] Bitter melon is extracted with ethanol, the extract is concentrated, dried, crushed, and passed th...

Embodiment 2

[0040] Ethanol extraction of 60 parts of flour, 8 parts of wheat bran puffed powder prepared in Example 1, 8 parts of bean dregs puffed powder prepared in Example 1, 12 parts of puffed yam powder with skin prepared in Example 1, and balsam pear prepared in Example 1 3 parts, 2 parts of mulberry leaf aqueous extracts prepared in Example 1, 2 parts of xylooligosaccharides, 1 part of yeast, 3 parts of gluten powder and 1 part of compound enzyme preparation were mixed uniformly to obtain steamed bread powder.

[0041] Take 100g of steamed bread powder, add 56g of water and knead the dough to get the dough; put the dough at 32°C and 80% relative humidity to ferment to 2.5 times the original volume to get the fermented dough; the required fermentation time is 25min; The dough is made into a prescribed shape, and proofed at 30-35° C. for 20 minutes; the proofed dough is steamed to obtain steamed buns.

Embodiment 3

[0043] Ethanol extraction of 60 parts of flour, 8 parts of wheat bran puffed powder prepared in Example 1, 8 parts of bean dregs puffed powder prepared in Example 1, 12 parts of puffed yam powder with skin prepared in Example 1, and balsam pear prepared in Example 1 3 parts, 2 parts of mulberry leaf aqueous extract prepared in Example 1, 2 parts of xylooligosaccharides, 1 part of yeast and 1 part of compound enzyme preparation were mixed uniformly to obtain steamed bread powder.

[0044] Take 100g of steamed bread flour, add 56g of water and knead the dough to get the dough; put the dough in an environment of 32°C and 80% relative humidity to ferment to 2.5 times the original volume to get the fermented dough; the required fermentation time is 35min; The dough is made into a prescribed shape, and proofed at 30-35° C. for 20 minutes; the proofed dough is steamed to obtain steamed buns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com