Zwitterionic random copolymer surface modification coating with epoxy functional group, preparation method and application

A technology of random copolymers and epoxy functional groups, which can be used in coatings, drug delivery, and pharmaceutical formulations. It can solve the problems of weakened anticoagulant performance, achieve simple preparation technology, mild preparation conditions, and improve biocompatibility Effects on blood compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

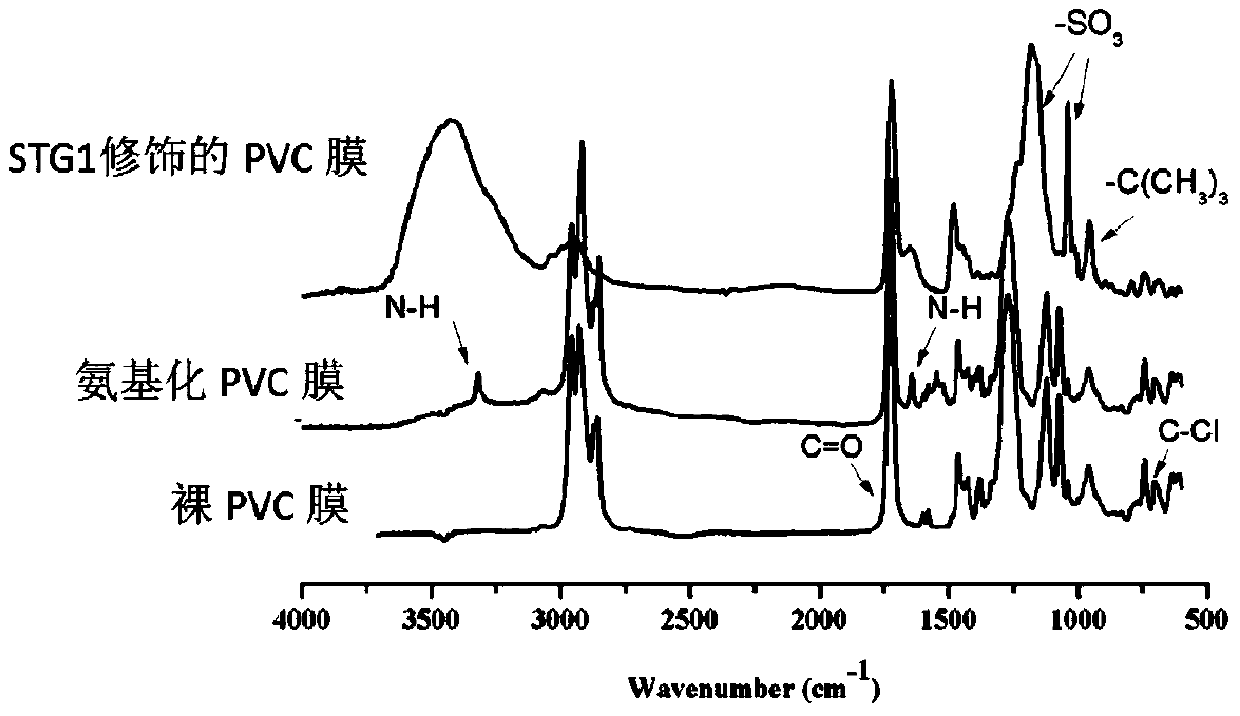

[0027] Preparation of poly(SA-TMA-GMA) coating on the surface of polyvinyl chloride (PVC) film

[0028]First, the PVC membrane was cleaned with ethanol aqueous solution for 30 min in an ultrasonic cleaner and dried in a nitrogen stream.

[0029] Then, add ethylenediamine aqueous solution with a concentration of 70% into the reaction bottle, and then quickly immerse the PVC film in the ethylenediamine aqueous solution, and react at 80° C. for 1 hour. After the reaction, wash the surface of PVC with a large amount of deionized water to remove unreacted ethylenediamine molecules on the surface, then dry it with nitrogen flow, and finally put the film in a vacuum drying oven and dry it to constant weight at room temperature to obtain PVC- NH 2 . The concentration of ethylenediamine aqueous solution, reaction temperature and time can be adjusted as required.

[0030] Finally, the surface-aminated PVC membrane was immersed in 10 mg / mL poly(SA-TMA-GMA) terpolymer STG1 in PBS buffe...

Embodiment 2~4

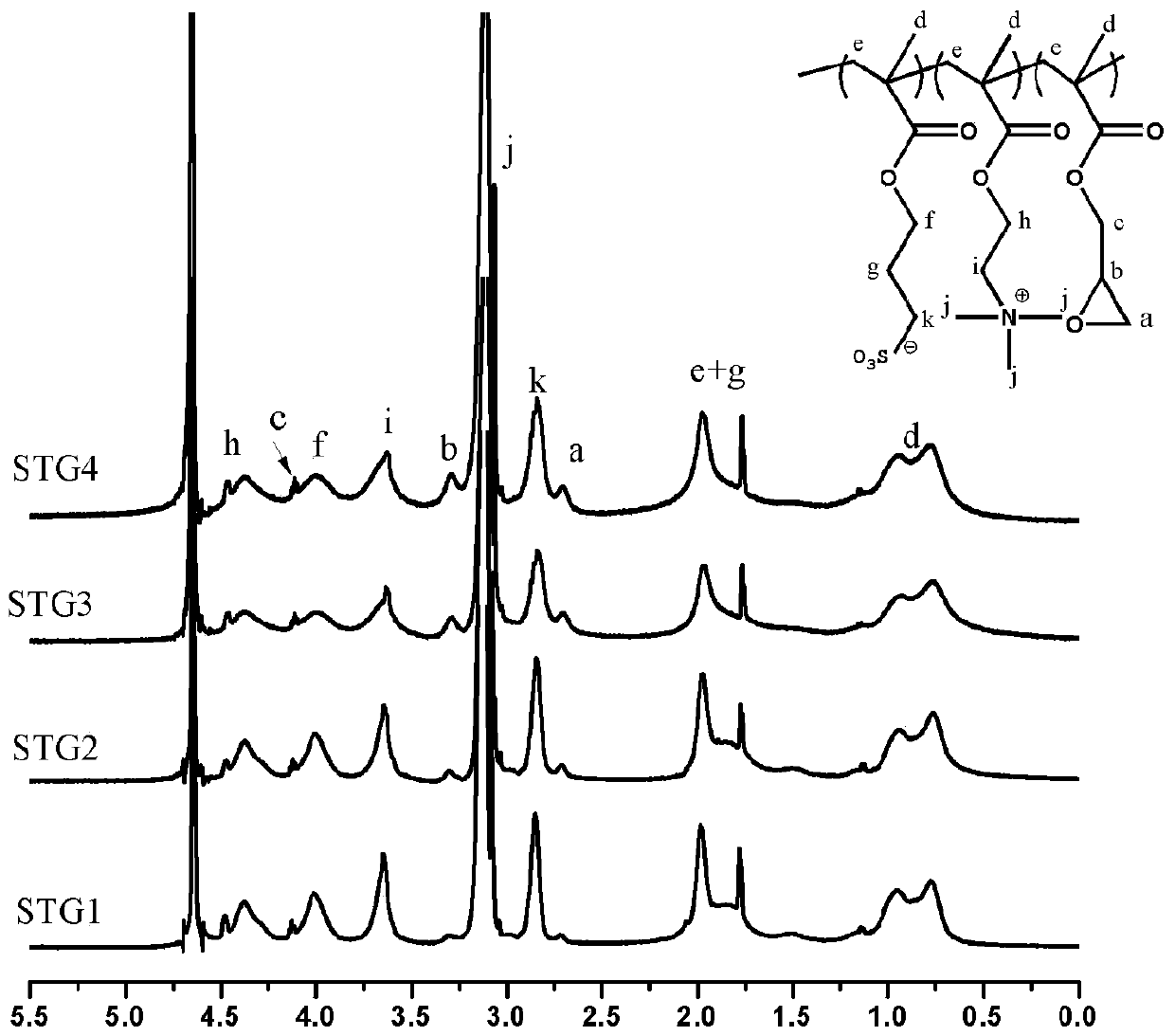

[0046] By the method of embodiment 1, the difference is that other composition poly(SA-TMA-GMA) ternary random copolymers are used instead of STG1 to modify the surface coating, as shown in Table 2 and image 3 .

Embodiment 5

[0048] According to the method of Example 10, a PVC pipe of 1 m was cleaned with ethanol aqueous solution for 30 min in an ultrasonic cleaner, and dried in a nitrogen stream. Then, a section of the PVC pipe was sealed, and a 70% aqueous solution of ethylenediamine was added into the pipe, and reacted at 80° C. for 1 h. After the reaction, rinse the PVC tube with a large amount of deionized water to remove unreacted ethylenediamine molecules on the surface, and then inject 10 mg / mL poly(SA-TMA-GMA) terpolymer STG1 in PBS into the tube Buffer solution, reacted at 60°C for 2h under shaking. The tubes were then removed and rinsed repeatedly with deionized water to remove physically attached copolymer to the surface. Finally, the film was put into a vacuum drying oven, and dried to a constant weight at room temperature to obtain a coating of the PVC pipe inner surface modification copolymer STG1. As in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com