3D flexible electrode or 3D flexible catalyst as well as preparation method and application thereof

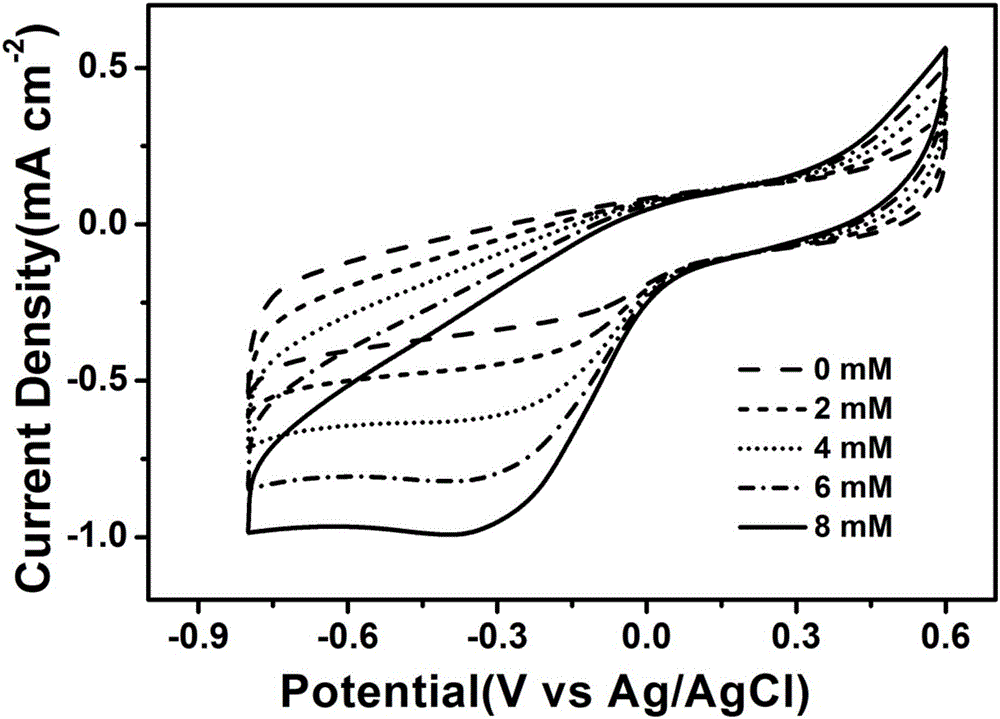

A flexible catalyst and flexible electrode technology, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, electrochemical variables of materials, etc., can solve the problem of limited surface area of carbon fibers, low activity of loaded nanomaterials, etc. problems, to achieve the effects of easy infiltration and penetration, enhanced analytical sensitivity, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

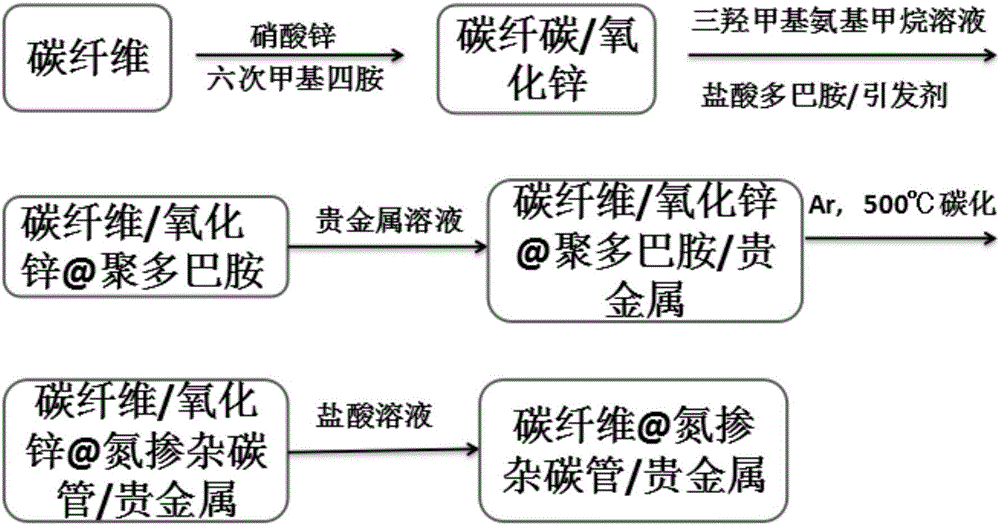

Method used

Image

Examples

Embodiment 1

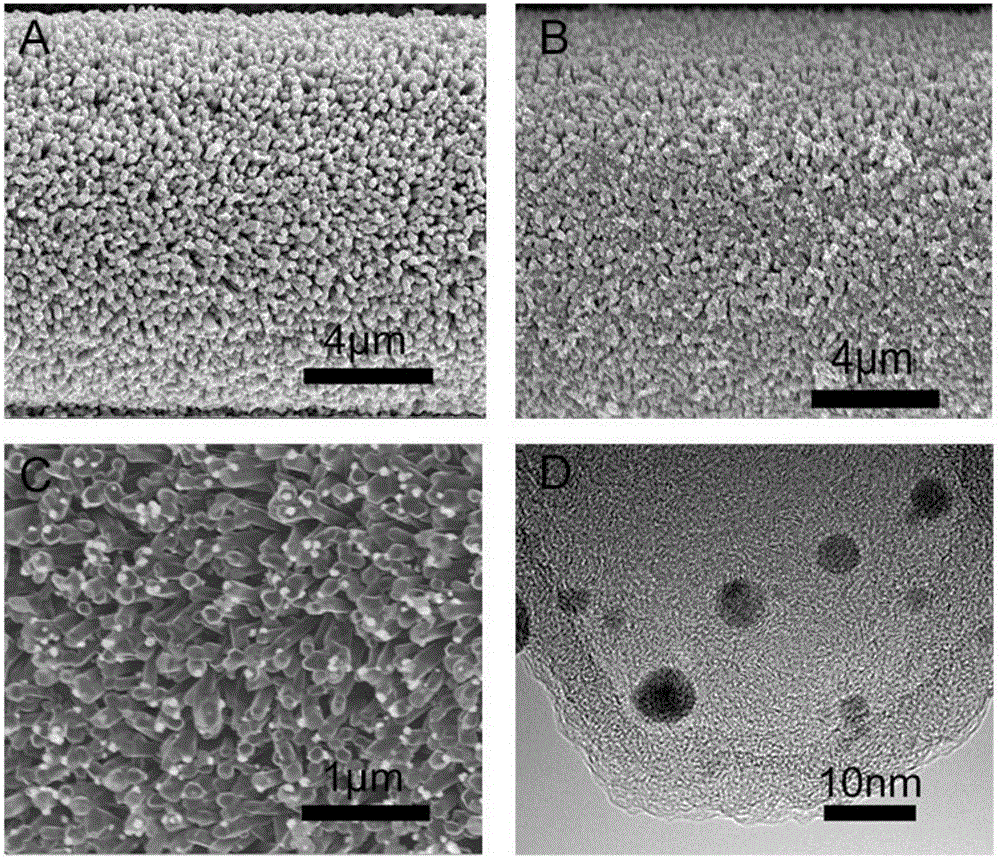

[0035] Synthesis of carbon fiber@nitrogen-doped carbon tube / gold composite:

[0036] 1) Synthesis of carbon fiber / zinc oxide composite material (that is, carbon fiber with zinc oxide crystals growing on the surface): the carbon fiber is placed in 30% hydrogen peroxide (that is, an aqueous hydrogen peroxide solution with a hydrogen peroxide mass percentage concentration of 30%) for 12h to obtain the oxidized The carbon fibers were washed and dried with deionized water; then the oxidized carbon fibers were soaked in a mixed solution of 0.01M zinc acetate and 0.01M ethylenediamine with ethylene glycol methyl ether (CAS number: 109-86-4) as a solvent In the process, zinc oxide seeds (the zinc oxide seed crystals are grown on carbon fibers) were crystallized and grown in a muffle furnace at 300 °C; then the carbon fibers on which the zinc oxide seeds were grown were placed in a place containing both 0.1M zinc nitrate hexahydrate and 0.1M hexahydrate. In the methinetetramine mixed s...

Embodiment 2

[0042] Synthesis of carbon fiber@nitrogen-doped carbon tube / palladium composite:

[0043] 1) Synthesis of carbon fiber / zinc oxide composite material: carbon fiber was placed in 30% hydrogen peroxide for 12h, washed and dried with deionized water; then the oxidized carbon fiber was soaked in 0.01M zinc acetate with ethylene glycol methyl ether as solvent and 0.01M ethylenediamine mixed solution to crystallize and grow zinc oxide seeds in a muffle furnace at 300°C; then place the carbon fibers on which the zinc oxide seeds were grown in a solution containing 0.1M zinc nitrate hexahydrate and 0.1M hexamethylenetetramine. In the mixed solution, a precursor is obtained; then, the precursor is placed in a reaction kettle, and the reaction kettle is placed in an oven at 95 ° C for hydrothermal reaction for 12 hours to obtain a carbon fiber / zinc oxide composite material;

[0044] 2) Synthesis of carbon fiber / zinc oxide@polydopamine composite material: dissolve tris(hydroxymethyl)amino...

Embodiment 3

[0049] Synthesis of carbon fiber@nitrogen-doped carbon tube / gold composite:

[0050] 1) Synthesis of carbon fiber / zinc oxide composite material: carbon fiber was placed in 30% hydrogen peroxide for 12h, washed and dried with deionized water; then the oxidized carbon fiber was soaked in 0.01M zinc acetate with ethylene glycol methyl ether as solvent and 0.01M ethylenediamine mixed solution to crystallize and grow zinc oxide seeds in a muffle furnace at 300°C; then place the carbon fibers on which the zinc oxide seeds were grown in a solution containing 0.1M zinc nitrate hexahydrate and 0.1M hexamethylenetetramine. In the mixed solution, a precursor is obtained; then, the precursor is placed in a reaction kettle, and the reaction kettle is placed in an oven at 95 ° C for hydrothermal reaction for 12 hours to obtain a carbon fiber / zinc oxide composite material;

[0051]2) Synthesis of carbon fiber / zinc oxide@polydopamine composite material: dissolve tris(hydroxymethyl)aminomethan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com