Preparation method for high-purity breviscapine extract as well as preparations and application thereof

A technology of scutellarin and extracts, which is applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problems of low purity, roughness, and high impurity content of ingredients, and achieve fast separation speed and load sample volume Large, large separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

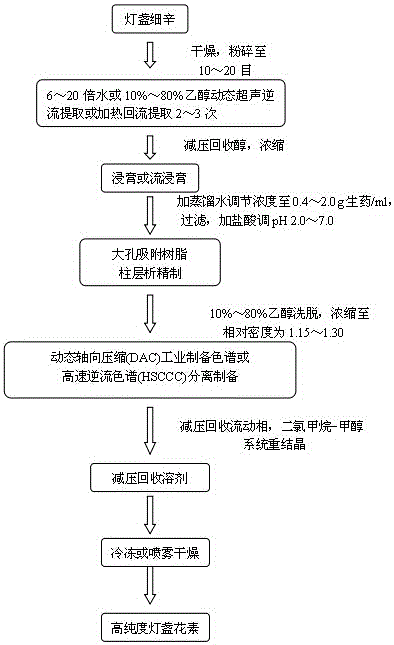

[0021] Example 1 High-purity breviscapine extract was prepared by dynamic ultrasonic countercurrent extraction combined with macroporous adsorption resin column chromatography and dynamic axial compression industrial preparation chromatographic separation technology

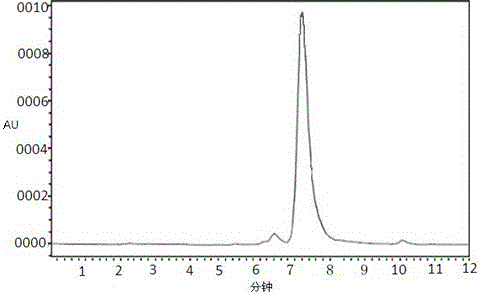

[0022] Crush 10 kg of Erigeron breviscapus to 20-30 meshes, add 8 times the amount of ethanol with a concentration of 70% by volume, extract continuously at a frequency of 30 kHz, and ultrasonic power 20 kW for 3 times, each time for 40 min, filter, and combine the extracts , recover the extraction solvent under reduced pressure, properly concentrate to a concentration of 0.6 g crude drug / ml, add 1 mol / L hydrochloric acid to adjust the pH value to 4, and pass through the HPD650 macroporous adsorption resin chromatography column at a flow rate of 2BV / h. The ratio of solid matter to dry resin is 1:6, and the ratio of diameter to height is 1:8. First wash the resin column bed with 4 BV of distilled water, and the elu...

Embodiment 2

[0023] Example 2 Preparation of High Purity Breviscapine Extract by Heating Reflux Extraction Combined with Macroporous Adsorption Resin Column Chromatography and High Speed Counter-Current Chromatography

[0024] Add 15 times the amount of ethanol with a volume percentage concentration of 80% to 2 kg of Erigeron breviscapus crushed to 20-30 mesh, heat and reflux for extraction 3 times, each time for 1.5 h, filter, combine the extracts, and concentrate to a concentration of 1.0 g Crude drug / ml, after filtering, add 1mol / L hydrochloric acid to adjust the pH value to 4-5, and pass through the HPD400 macroporous adsorption resin chromatography column at a flow rate of 3BV / h. The ratio of the sample solution to the dry resin is 1: 8. The diameter-to-height ratio is 1:10. First wash the resin with 6 BV of water, the elution flow rate is 4 BV / h, discard the water eluent; then elute with methanol with a concentration of 60% by volume. The flow rate is 3 BV / h, the eluent is decompre...

Embodiment 3

[0025] Example 3 Preparation of high-purity breviscapine extract by heating reflux extraction combined with macroporous adsorption resin column chromatography and dynamic axial compression industrial preparation chromatographic separation technology

[0026] 5 kg of Asarum breviscapus was moderately crushed, and 10 times the amount of 60% methanol was added, and the frequency was 30 kHz, the ultrasonic power was 20 kW, and the ultrasonic power was continuously ultrasonically countercurrently extracted 3 times, each time for 0.5 h, filtered, combined extracts, methanol was recovered under reduced pressure, and water was added to adjust Concentration to 1.5 g crude drug / ml, add 1 mol / L hydrochloric acid to adjust the pH value to 6, pass through the SP825 macroporous adsorption resin chromatography column twice at a flow rate of 2BV / h, and load the sample solution according to the ratio of solid content to dry resin 1:9, the ratio of diameter to height is 1:8, wash the resin with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com