Preparation method of composite carboxymethyl chitosan/graphene oxide/polyacrylamide hydrogel

A technology of carboxymethyl chitosan and composite hydrogel is applied in the field of preparation of carboxymethyl chitosan/graphene oxide/polyacrylamide composite hydrogel, which can solve the problem of low elongation at break, low tensile strength problems such as poor tensile strength and mechanical properties, to achieve the effects of good biocompatibility, improved mechanical properties, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

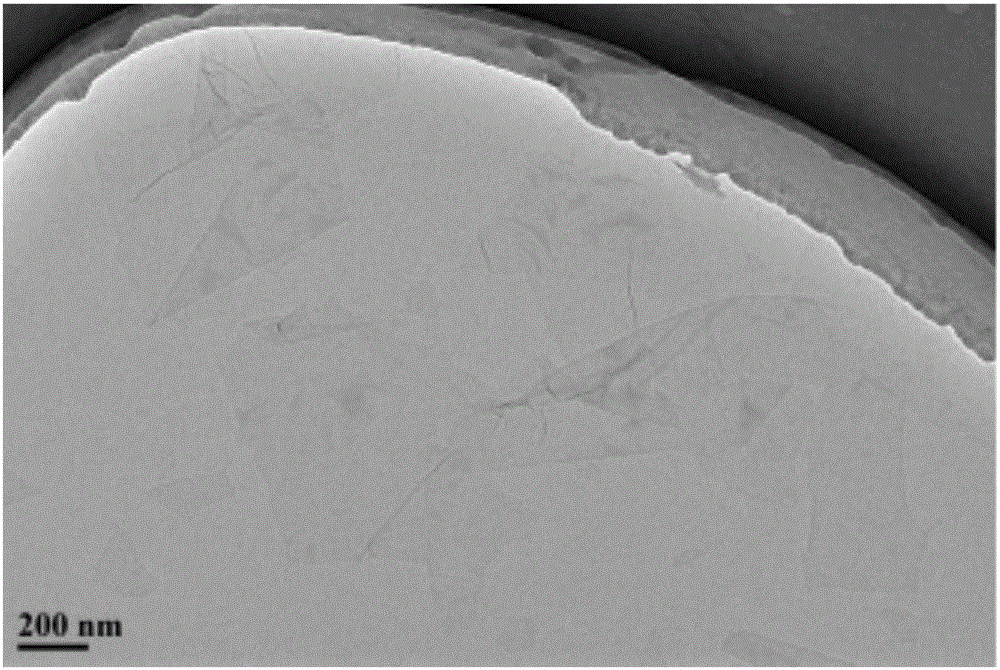

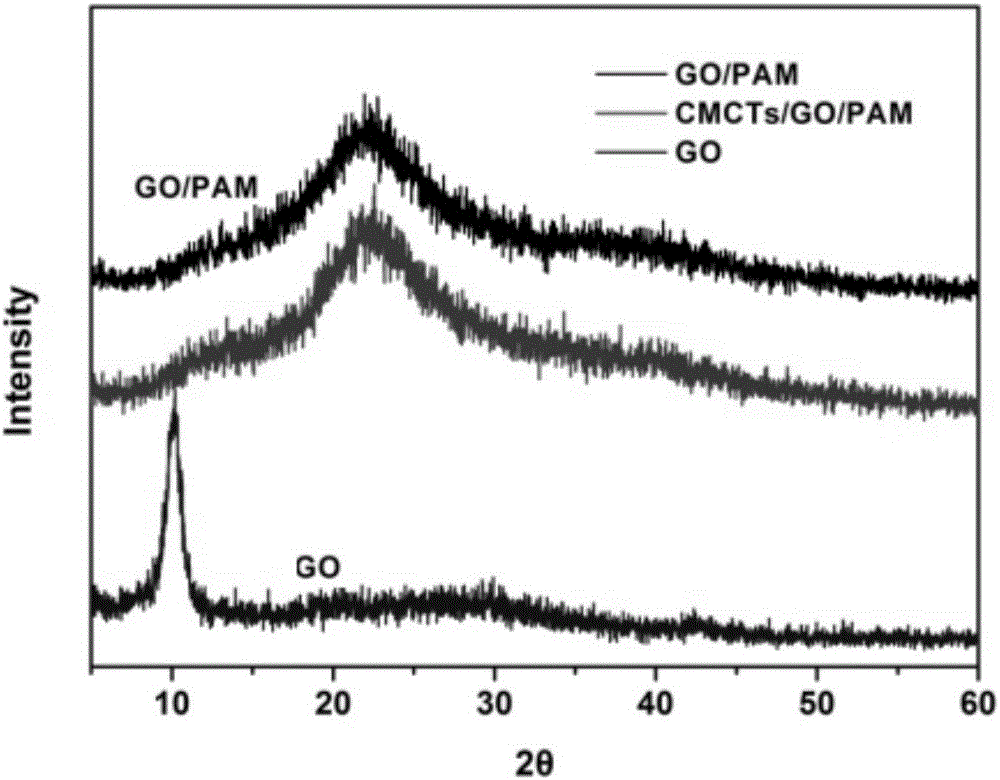

Image

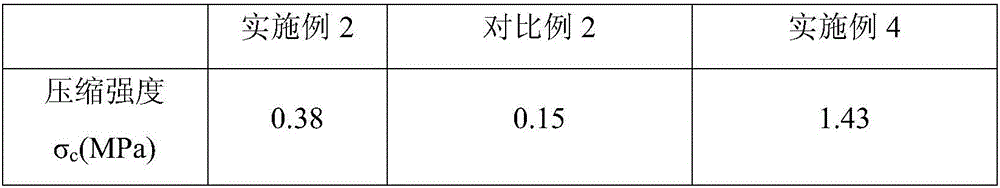

Examples

Embodiment 1

[0034] The preparation method of carboxymethyl chitosan:

[0035] A: First soak 5g of chitosan in 45ml of isopropanol and swell at room temperature for 17h, then add 30g of 50wt% sodium hydroxide solution for alkalization for 2h, stir mechanically at 50°C, and add in isopropanol drop by drop. The chloroacetic acid solution of propanol (8.5g chloroacetic acid is dissolved in 5ml isopropanol), reacted 4h, the product obtained was first washed with 1wt% dilute hydrochloric acid until it was close to neutrality, and then the volume fraction was 90% ethanol, no Wash with water and ethanol for 3-4 times, filter with suction, and dry in an oven at 45° C. to obtain crude carboxymethyl chitosan.

[0036] B: Dissolve the crude product in deionized water, stir to make it fully dissolved, add excess acetone to precipitate carboxymethyl chitosan, and wash the precipitated carboxymethyl chitosan with absolute ethanol 3-4 times, then vacuum Dried in an oven to obtain pure carboxymethyl chit...

Embodiment 2

[0046] The preparation method of carboxymethyl chitosan is identical with embodiment.

[0047] Preparation method of carboxymethyl chitosan / graphene oxide / polyacrylamide composite hydrogel

[0048] (1) Preparation of graphene oxide aqueous solution: Weigh 0.3g of graphite oxide powder, add it to a 250ml beaker, add 150ml of deionized water, stir for 3h to make it evenly dispersed; use a cell pulverizer to crush and peel off for 1h, and centrifuge at 600rpm for 1h to remove After the lower layer is precipitated, centrifuge at 10,000rpm for 2 hours to remove the upper layer solution, add deionized water to the lower layer of precipitation, and stir evenly to obtain a graphene oxide aqueous solution with a concentration of 3.68 mg / ml;

[0049] (2) Prepare initiator aqueous solution: take by weighing initiator potassium persulfate 2g and dissolve 100ml deionized water, fully stir and make it dissolve completely, obtain the potassium persulfate aqueous solution that concentration i...

Embodiment 3

[0055] The preparation method of carboxymethyl chitosan is with embodiment 1.

[0056] (1) Preparation of graphene oxide aqueous solution: Weigh 0.3g of graphite oxide powder, add it to a 250ml beaker, add 150ml of deionized water, stir for 3h to make it evenly dispersed; use a cell pulverizer to crush and peel off for 1h, and centrifuge at 600rpm for 1h to remove After the lower layer is precipitated, centrifuge at 10,000rpm for 2 hours to remove the upper layer solution, add deionized water to the lower layer of sediment, and stir evenly to obtain a graphene oxide aqueous solution with a concentration of 3.46mg / ml;

[0057] (2) Prepare initiator aqueous solution: take by weighing initiator potassium persulfate 2g and dissolve 100ml deionized water, fully stir and make it dissolve completely, obtain the potassium persulfate aqueous solution that concentration is 0.02g / ml;

[0058] (3) Preparation of carboxymethyl chitosan / graphene oxide / polyacrylamide composite hydrogel: add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com