Automatic liquid glucose carbon addition type syrup color removal method

A technology for preparing carbon and sugar solution, which is applied in the fields of purification, sugar production, and sucrose production using physical methods. Comprehensive production costs and other issues, to achieve the effect of reducing labor and comprehensive production costs, good industrial application prospects and value, and reducing steam consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

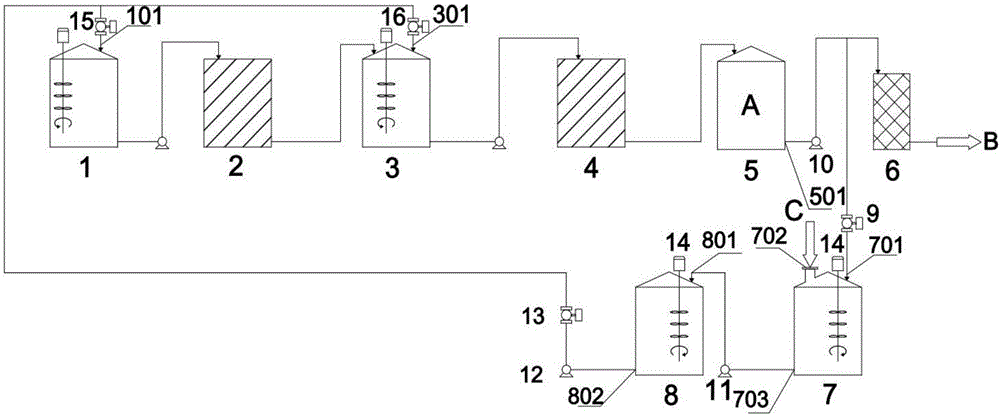

[0018] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but the claims of the present invention are not limited in any way.

[0019] like figure 1 Shown is the sugar carbonation decolorization system adopted in this embodiment, which includes a first-stage decolorization tank 1, a first-stage plate and frame filter 2, a second-stage decolorization tank 3, a second-stage plate and frame filter 4, and a decolorization tank in series. Front tank 5, fine filter 6, on the basis of the passage, additionally set a carbon tank 7 and a carbon tank 8; the carbon tank 7 is provided with a sugar liquid return port 701, a carbon powder feeding port 702 and a liquid outlet 703 , the carbon adding tank 8 is provided with a sugar and carbon mixed liquid inlet 801 and a liquid outlet 802, and a liquid outlet 501 is additionally provided on the pre-delivery tank 5, and a first-level decolorization tank 1 and a second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com