Copper-nickel alloy powder for ultralow-resistance chip resistor

A chip resistor and alloy powder technology, which is applied in the direction of resistors, thick film resistors, non-adjustable metal resistors, etc., can solve the problem of poor linearity of resistance of copper-manganese alloy powder, high control standard of oxygen content in the atmosphere, and the use of temperature range Narrow and other problems, to achieve the effect of improving the temperature coefficient of resistance, low price, and wide temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

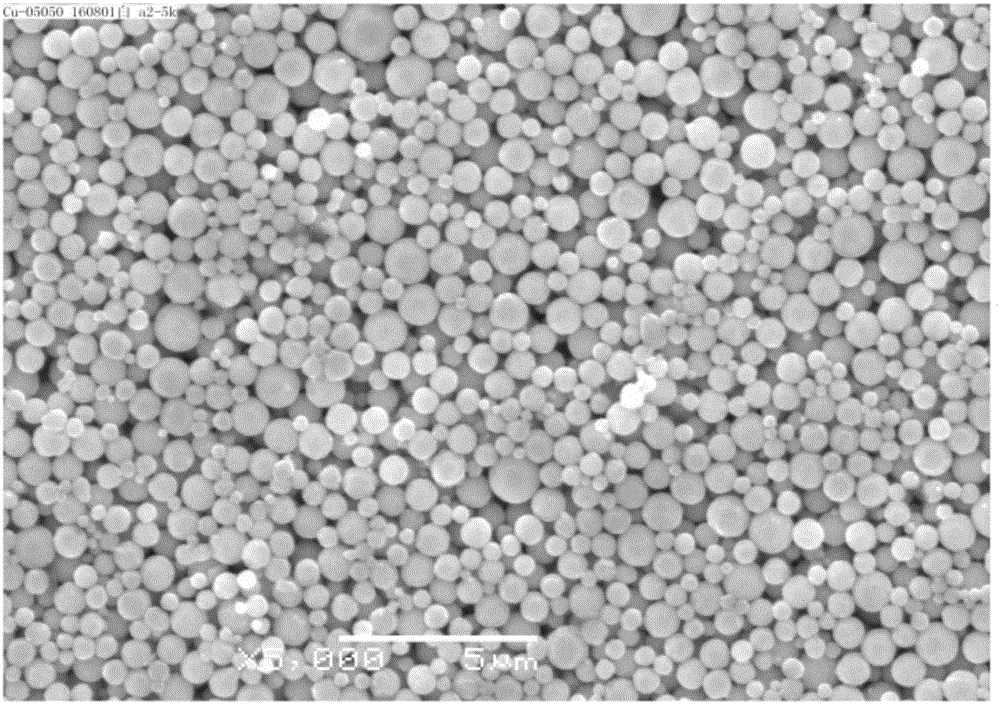

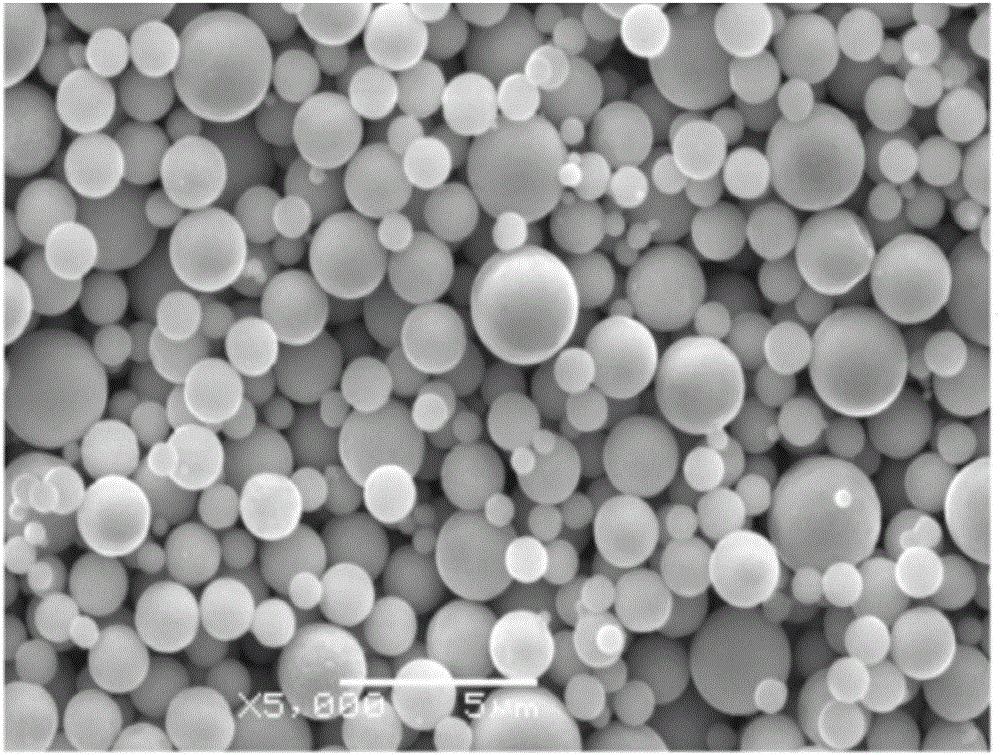

[0032] Example 1. Preparation of Cu59Ni40Mn0.5Fe0.5 copper-nickel alloy powder with a particle size of 2 μm.

[0033] Firstly, according to the required molar ratio of the above-mentioned copper-nickel alloys, the mass of Cu, Ni, Mn and Fe is prepared, placed in an induction furnace and smelted into copper-nickel alloys.

[0034] Put the alloy block into the crucible of the high-temperature metal evaporator, and install the plasma generating device (for details, please refer to ZL201110119245.2, Metal Evaporation Device and the Method for Using the Device to Prepare Ultrafine Metal Powder, and the specific preparation will not be described in detail here. process), and check the airtightness, evacuate well, pour nitrogen into the system to make the whole system under the inert gas atmosphere, control the pressure in the crucible, start the plasma generator, set the power at 30KW, and increase the power of the plasma gun after 2 hours of heat preservation To 90KW, start the con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| oxygen content | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com