Self-fragrant natural anti-bacterial deodorizing fiber

A natural antibacterial and fragrant technology, used in fiber processing, conjugated synthetic polymer rayon, filament/thread forming, etc., can solve the problem of affecting the application of silver ion antibacterial agent, silver ion turning black, and poor anti-discoloration ability and other problems, to achieve the effect of ensuring washing resistance, antibacterial and deodorizing effects, uniform fragrance release, and long fragrance persistence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

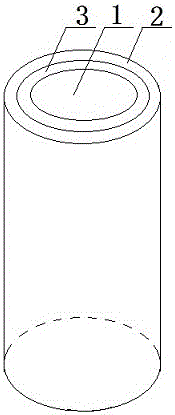

[0048] as attached figure 1 As shown, the self-fragrant natural antibacterial and deodorant fiber described in this embodiment has a skin-core structure, including a core layer 1 and a skin layer 2, the core layer 1 is a high-melting point polymer, and the skin layer 2 is a low-melting point polymer. Its structural feature is that the high-melting-point polymer body of the core layer 1 contains an aromatic slow-release body and a natural antibacterial composition. Wherein, the high melting point polymer is preferably polyethylene terephthalate, polybutylene terephthalate, polypropylene or polylactic acid; the low melting point polymer is preferably polyethylene.

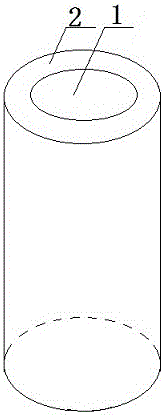

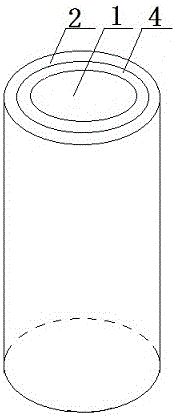

[0049] as attached figure 2 , image 3 and Figure 4 As shown, the high-melting polymer body as the aromatic natural antibacterial and deodorant fiber core layer 1 is also in a skin-core structure, that is, between the fiber core layer 1 and the fiber skin layer 2, a fragrance slow-release layer 3 or a natural an...

Embodiment 2

[0054] In this example, the preparation of self-fragrance natural antibacterial deodorant fiber includes the preparation of fragrance slow-release body, the preparation of natural antibacterial deodorant composition, the preparation of self-fragrant natural antibacterial deodorant masterbatch and the preparation of self-fragrant natural antibacterial deodorant fiber The preparation, concrete preparation process and steps are as follows:

[0055]1) Preparation of aromatic slow-release body: In this process, the fragrance slow-release body adopts spray-drying microcapsule technology, the polymer of the capsule wall is gum arabic, and the fragrance type of the aromatic essential oil in the capsule core is selected from jasmine essential oil, calculated according to the mass ratio , gum arabic: jasmine essential oil is 40%:60%, and emulsifier selects Span-80 for use, and its mass ratio is 0.5% of jasmine essential oil amount, and its preparation process comprises the following step...

Embodiment 3

[0076] In the present embodiment, the specific preparation process and steps of self-fragrant natural antibacterial and deodorant fiber are as follows:

[0077] 1) Preparation of aromatic slow-release body: In this process, the fragrance slow-release body adopts spray-drying microcapsule technology, the polymer of the capsule wall adopts urea-formaldehyde resin prepolymer, and the fragrance type of the aromatic essential oil in the capsule core is selected from lemon essential oil. Proportion calculation, ethylene-vinyl acetate copolymer: lemon essential oil is 60%:40%, emulsifier is selected sodium dodecylbenzene sulfonate, and its mass ratio is 0.8% of lemon essential oil, and its preparation process includes as follows step:

[0078] Step 1: Weigh 40 parts of lemon essential oil, add emulsifier sodium dodecylbenzenesulfonate into the essential oil, stir to dissolve and form an oil phase.

[0079] Step 2: Weigh 60 parts of a solution configured with a concentration of 10% i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com