Secondary bismuth oxychloride/nickel hydroxide alkaline battery and preparation method thereof

A technology of bismuth oxychloride and nickel hydroxide is applied in the field of electrochemical energy storage, which can solve the problems that have not been seen before, and achieve the effects of large electric capacity, excellent electrical performance and long cycle life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) Weigh 10mmol bismuth chloride, dissolve it in 20ml of hydrochloric acid solution with a concentration of 2mol / L, slowly add 29.75ml of 2mol / L sodium acetate solution dropwise while stirring at room temperature, after the dropwise addition, fully stir again After 30 minutes, the final pH of the system was 3, and the white precipitate was washed several times with distilled water and ethanol, respectively, and filtered with suction. Dry the solid product at a temperature of 120°C to a constant weight to obtain bismuth oxychloride material.

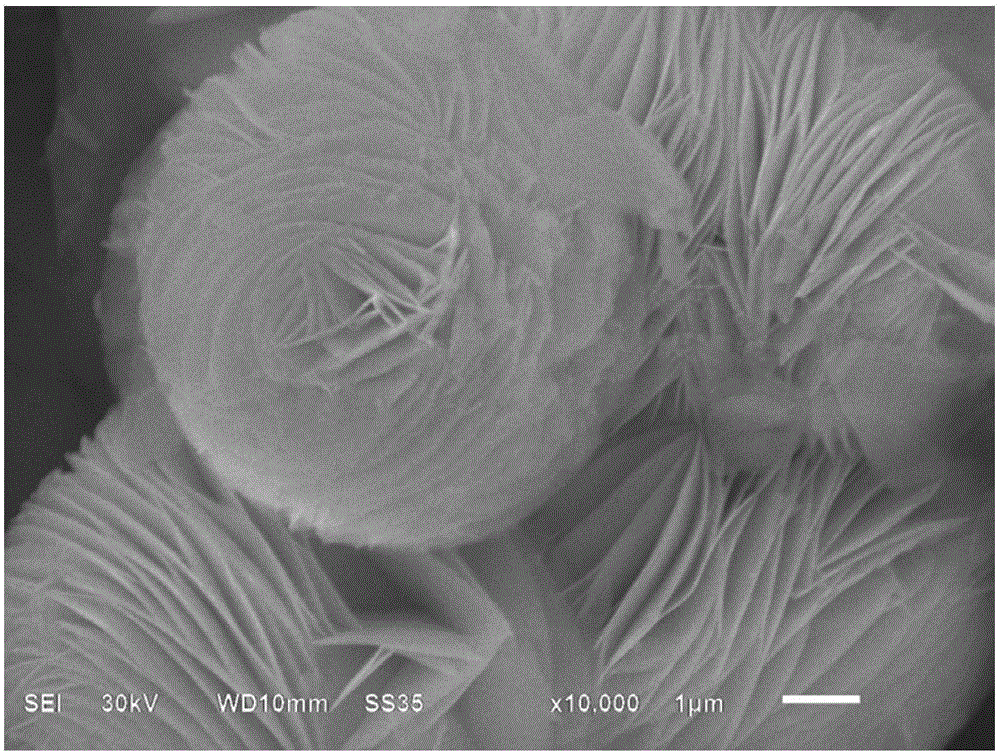

[0048] (2) Adopt JEOLJEM-3010 type scanning electron microscope to test the prepared material of embodiment 1 step (1), as figure 1 As shown, the bismuth oxychloride material has a microsphere structure, and the microspheres are stacked by nanosheets, the diameter of the microspheres is about 6 μm, and the thickness of the nanosheets is about 60 nm.

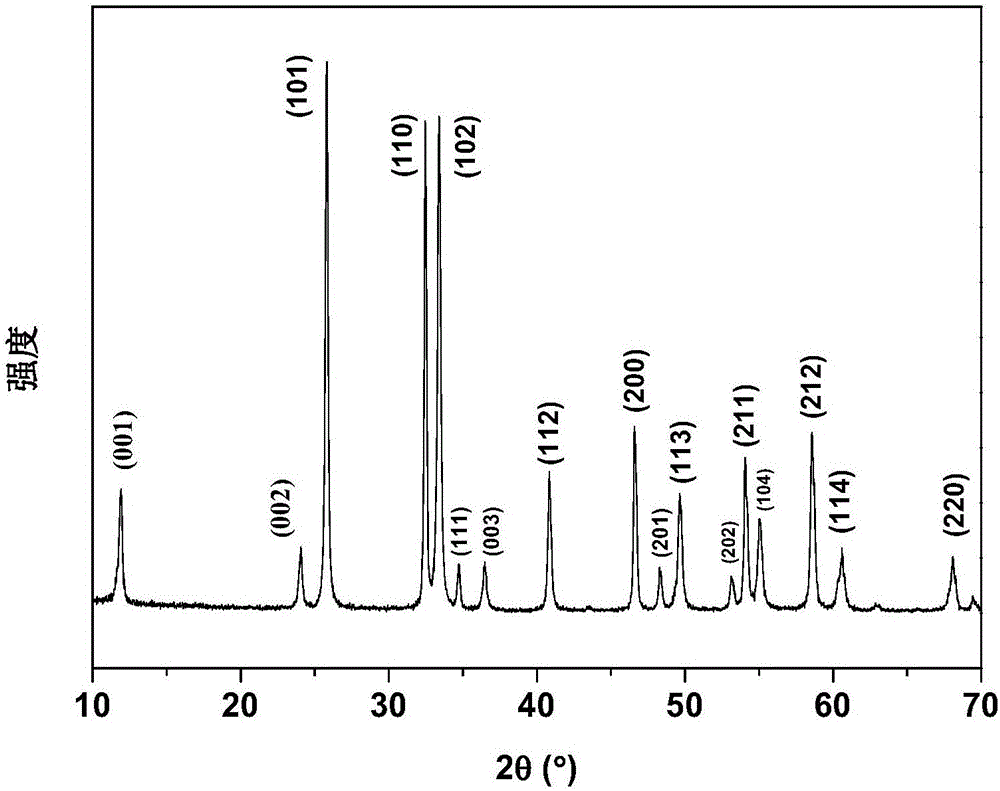

[0049] (3) adopt XRD-6000 type X-ray diffractometer to test the prepared materi...

Embodiment 2

[0055] (1) Weigh 4mmol bismuth chloride, dissolve it in 20ml of nitric acid solution with a concentration of 4mol / L, raise the temperature to 50°C, add 160ml of 2mol / L triethanolamine solution dropwise while stirring, and stir fully after the addition is completed After 120 minutes, the final pH of the system was 3, and the obtained white product was washed several times with distilled water and ethanol, respectively, and suction-filtered. The solid product was vacuum-dried at 80° C. to constant weight to obtain a bismuth oxychloride material.

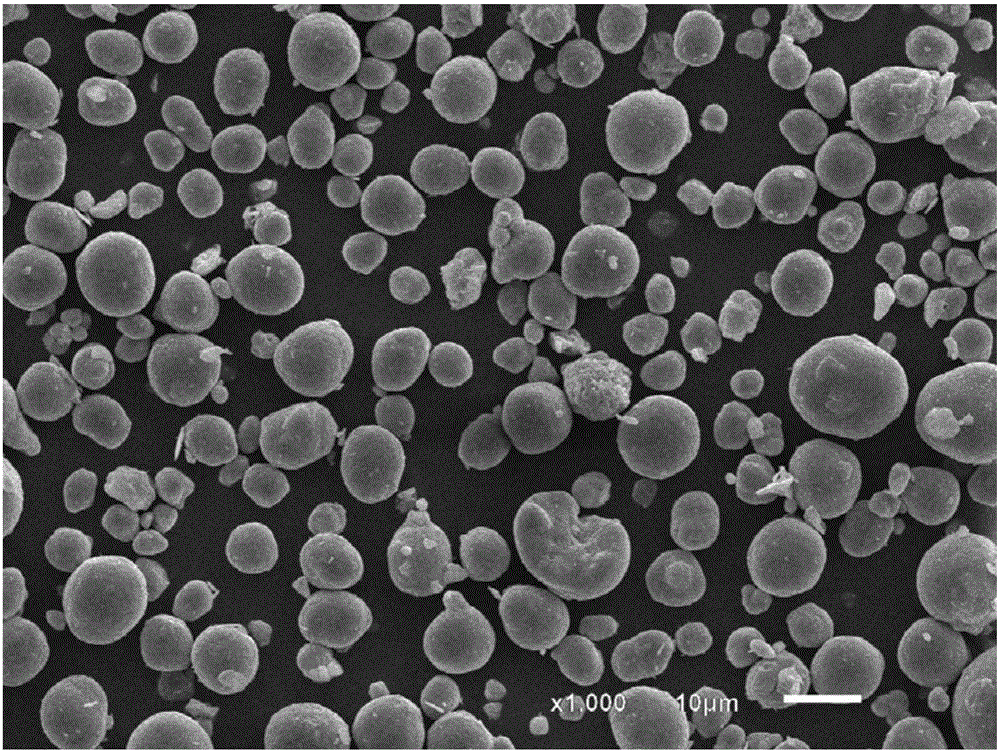

[0056] (2) Adopt JEOLJEM-3010 scanning electron microscope to characterize the spherical nickel hydroxide material adopted, such as figure 2 As shown, the nickel hydroxide material is a microsphere with a diameter of about 5-15 μm.

[0057] Elemental analysis shows that the nickel hydroxide material used has a β crystal structure, and the mass percentages of the elements contained in the nickel hydroxide material are 48-63% nickel, 0...

Embodiment 3

[0063] (1) Weigh 10 mmol of bismuth nitrate, disperse it in 20 ml of distilled water, and ultrasonically hydrolyze it for 30 min to form a suspension. While stirring at room temperature, add 20 ml of sodium chloride solution with a concentration of 5 mol / L dropwise, and react for 150 minutes after the dropwise addition is completed. The final pH of the system is 4. The resulting white precipitate is washed with distilled water and ethanol several times, and pumped. filter. The solid product was vacuum-dried at a temperature of 100° C. to a constant weight to obtain a bismuth oxychloride material.

[0064] Steps (2), (3) are respectively the same as steps (4), (5) in Example 1.

[0065](4) The CHI660A electrochemical workstation produced by Shanghai Chenhua Company was used to conduct cyclic voltammetry tests on the constructed batteries at room temperature, with a voltage window of 0.4-1.3V and a scan rate of 5mV / s. Such as Figure 7 Shown are the voltammetric curves of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com