Supported magnetic nano-palladium/gold catalyst and preparation method and application thereof

A magnetic nano and gold catalyst technology, applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the cumbersome preparation process of catalysts and the toxicity of modifying reagents , Increase catalyst cost and other issues, achieve the effect of reducing preparation cost, avoiding secondary pollution, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

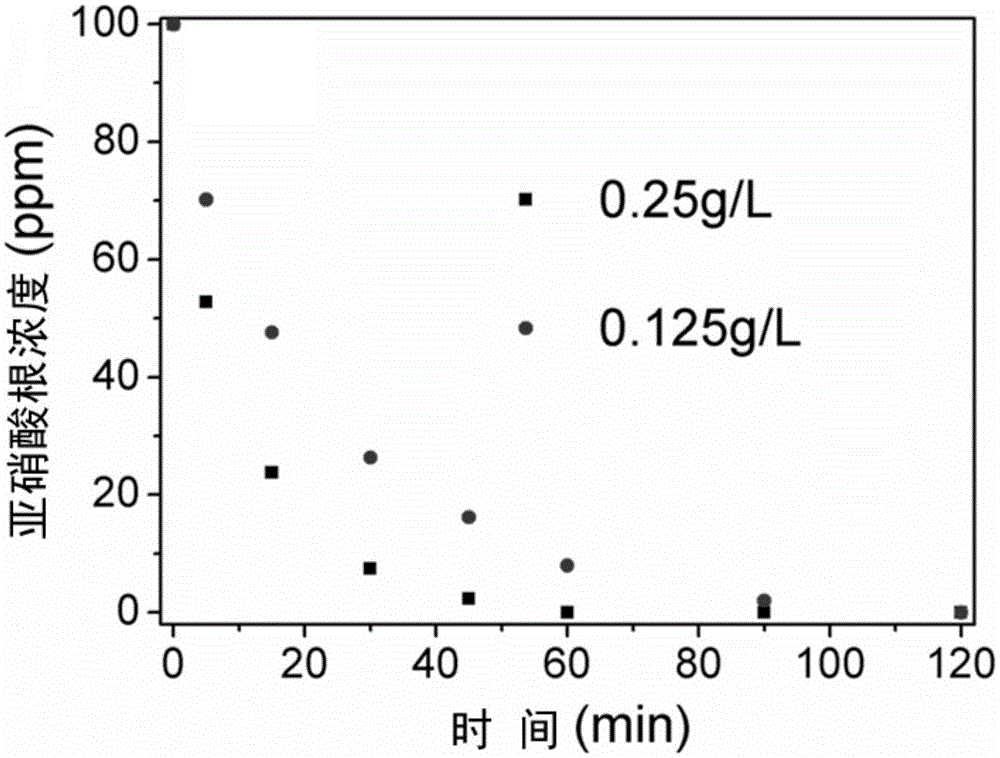

Examples

Embodiment 1

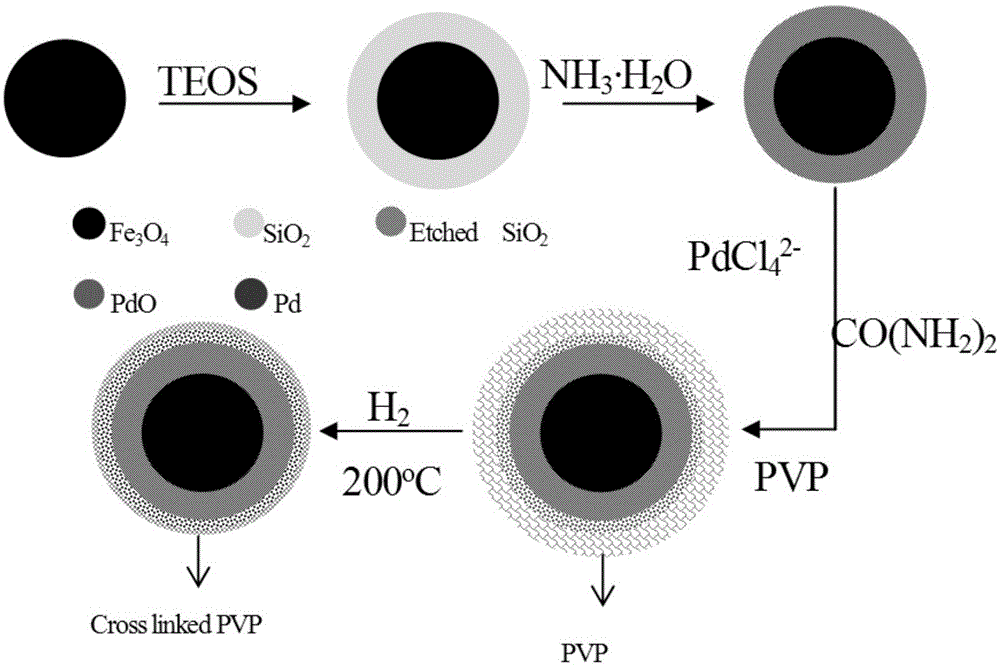

[0046] Dissolve 2.77 grams of ferric chloride hexahydrate and 0.2 ethylenediaminetetraacetic acid disodium in 80 milliliters of ethylene glycol, stir for 30 minutes and then ultrasonically treat it for 1 hour, then place the resulting colloidal solution in a hydrothermal kettle at 200°C for reaction After 10 hours, the product obtained was washed three times with ethanol and water respectively, dispersed in 40 ml of 2 g / L sodium citrate solution, magnetically separated after ultrasonication for 30 minutes, washed twice with deionized water, and finally dispersed in 40 ml deionized water. The product of this step is monodisperse iron ferric oxide nanospheres, and the particle size distribution is between 180-220nm.

[0047] 0.6 g of Fe3O4 nanospheres were ultrasonically dispersed in a mixed solution of ethanol / deionized water (320 ml / 80 ml), and 40 ml of 25 wt % ammonia water was added. Then, 10 milliliters of tetraethyl orthosilicate was added dropwise under stirring conditio...

Embodiment 2

[0051] The difference from Example 1 is:

[0052] Take 0.8% iron ferric oxide / silica core-shell structure carrier and disperse it in 400 ml of deionized water, add 4 g of polyvinylpyrrolidone, and disperse evenly under ultrasonic conditions. Heat to 60 degrees, then add 2 ml of 25wt% ammonia solution, and keep warm for 30 minutes under agitation. After magnetic separation, washing and drying, a rough-surfaced triiron tetroxide / silicon oxide core-shell structure carrier is obtained. Its specific surface area can reach 160 square meters per gram.

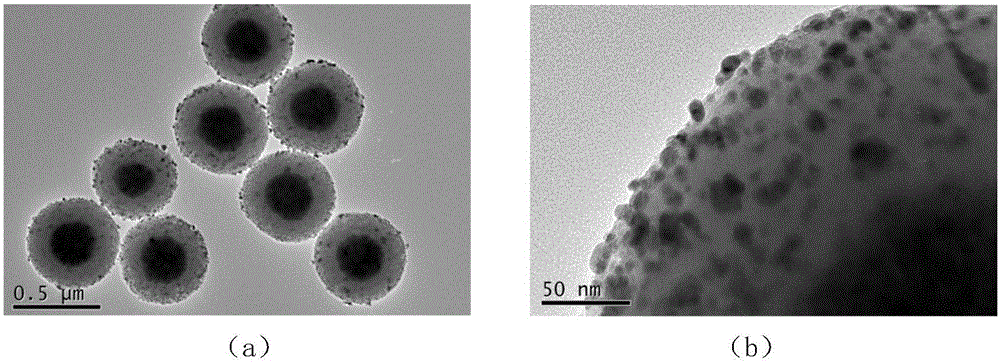

[0053] In the supported catalyst obtained in this example, the palladium particles are uniformly distributed on the surface of the rough ferric oxide / silica core-shell structure carrier, the loading amount of palladium is 5wt%, and the palladium particle size is 7nm.

Embodiment 3

[0055] The difference from Example 1 is:

[0056] Take 0.8% iron ferric oxide / silica core-shell structure carrier and disperse it in 400 ml of deionized water, add 4 g of polyvinylpyrrolidone, and disperse evenly under ultrasonic conditions. Heat to 60 degrees, then add 2 ml of 25 wt% ammonia solution, and keep warm for 1 hour under stirring condition. After magnetic separation, washing and drying, a rough-surfaced triiron tetroxide / silicon oxide core-shell structure carrier is obtained. Its specific surface area can reach 200 square meters per gram.

[0057] In the supported catalyst obtained in this example, the palladium particles are evenly distributed on the surface of the rough ferric oxide / silicon oxide core-shell structure carrier, the loading amount of palladium is 5wt%, and the palladium particle size is 3nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com