Silicon nitride nanowire preparation method, silicon nitride nanowire, silicon nitride powder and silicon nitride submicron powder

A technology of silicon nitride nanometer and silicon nitride powder, which is applied in chemical instruments and methods, nitrogen compounds, nanotechnology, etc., can solve the problems of difficult purification of silicon nitride, harsh process conditions, and difficulty in large-scale production equipment, and achieves High nitriding rate, high purity, and the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

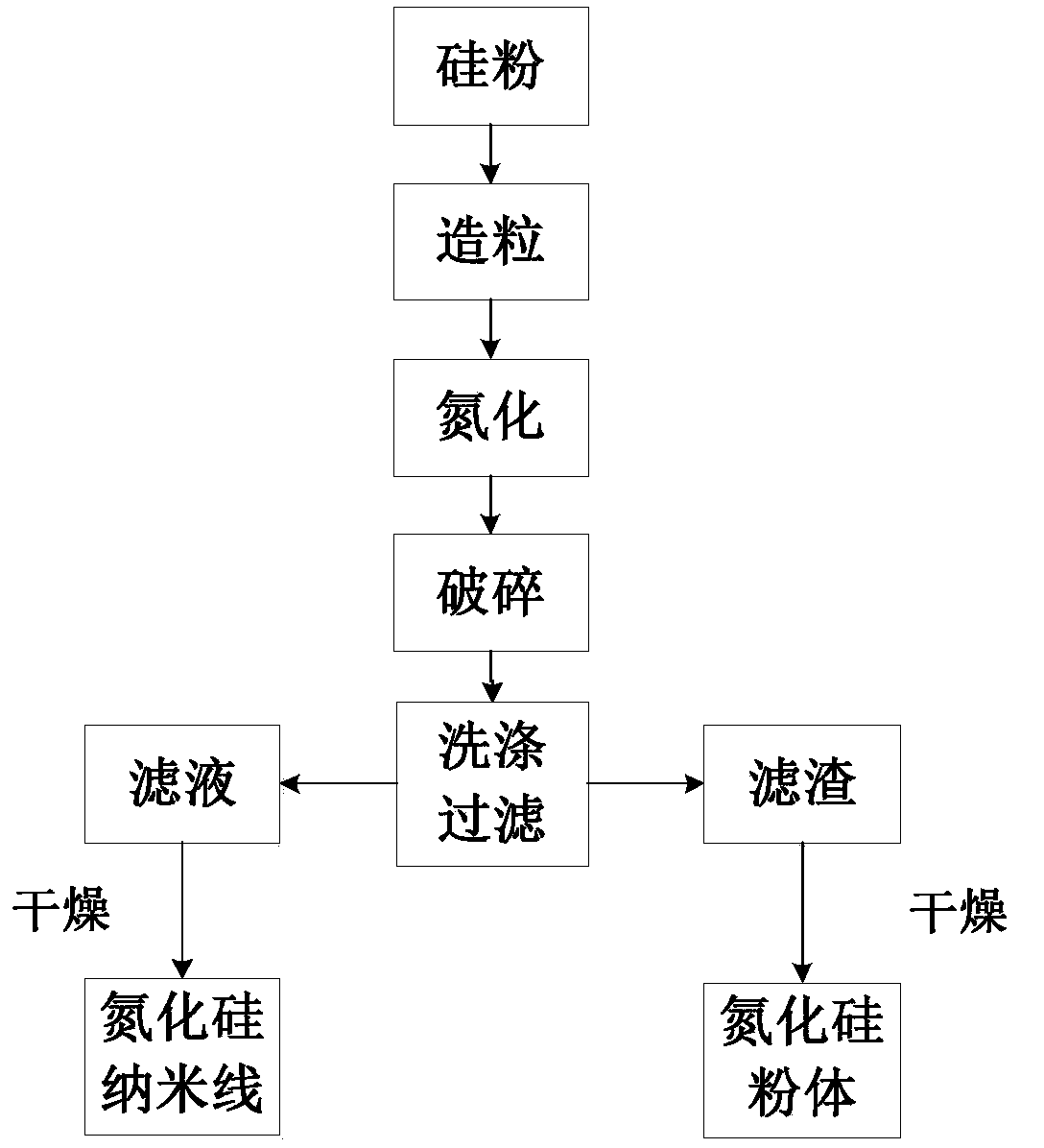

Method used

Image

Examples

Embodiment 1

[0045] (1) Granulation: at room temperature, add 1 wt% amylopectin into water, stir and slowly heat up to 80°C, and obtain transparent starch colloid after constant temperature for 1 hour;

[0046] Add silicon powder with irregular shape and particle size of 0.1-10 μm into the starch colloid, so that the solid content in the colloid after adding the silicon powder is 50wt% (starch / silicon particle=0.01, mass ratio), and then at 80°C Stirring under constant temperature conditions for 3 hours to obtain a suspension slurry;

[0047] Use a centrifugal spray dryer to granulate the above slurry, the feed rate is 0.5L / h, the nozzle temperature is 320°C, and the rotation speed is 20r / min. The obtained product is porous spherical particles with a size of 50-300μm , which is granulated silicon powder, and the microscopic appearance of the obtained granulated silicon powder is as follows figure 2 shown;

[0048] (2) Nitriding: Place granulated silicon powder in an inert atmosphere pro...

Embodiment 2

[0057] (1) Granulation: at room temperature, add 0.5 wt% amylopectin into water, stir and slowly heat up to 75°C, and obtain transparent starch colloid after constant temperature for 1.5 hours;

[0058] Add silicon powder with irregular shape and particle size of 0.1-10 μm into the starch colloid, so that the solid content in the colloid after adding the silicon powder is 50wt% (starch / silicon particles=0.005, mass ratio), and then at 75°C Stirring under constant temperature conditions for 2.5 hours to obtain a suspension slurry;

[0059] Use a centrifugal spray dryer to granulate the above slurry, the feed rate is 0.75L / h, the temperature of the nozzle is 320°C, and the rotation speed is 20r / min to obtain porous spherical particles with a size of 50-200μm, which is the production process. silicon powder;

[0060] (2) Nitriding: Place granulated silicon powder in an inert atmosphere protection furnace, feed a mixed gas of nitrogen and hydrogen (the volume fraction of hydrogen...

Embodiment 3

[0069] (1) Granulation: at room temperature, add 0.5 wt% amylose into water, stir and slowly heat up to 90°C, and obtain transparent starch colloid after constant temperature for 3 hours;

[0070] Add silicon powder with irregular shape and particle size of 0.1-10 μm into the starch colloid, so that the solid content in the colloid after adding the silicon powder is 50wt% (starch / silicon particle=0.005, mass ratio), and then at 90°C Stirring under constant temperature conditions for 3 hours to obtain a suspension slurry;

[0071] Use the centrifugal spray dryer to granulate the above slurry, the feed rate is 1L / h, the nozzle temperature is 350°C, and the rotation speed is 10r / min to obtain porous spherical particles with a size of 50-300μm, which is granulation Silica fume;

[0072] (2) Nitriding: Place granulated silicon powder in an inert atmosphere protection furnace, feed a mixed gas of nitrogen and hydrogen (the volume fraction of hydrogen is 15%) into the furnace as a r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com