Environment-friendly additional fertilizer and preparation method thereof

An environmentally friendly, sludge-based technology, applied in the preparation of organic fertilizers, nitrogen fertilizers, organic fertilizers, etc., can solve the problems of not being able to meet the needs of diversified planting, ignoring the importance of organic components, etc., to reduce pests and diseases, and improve fertilizer utilization. , the effect of promoting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

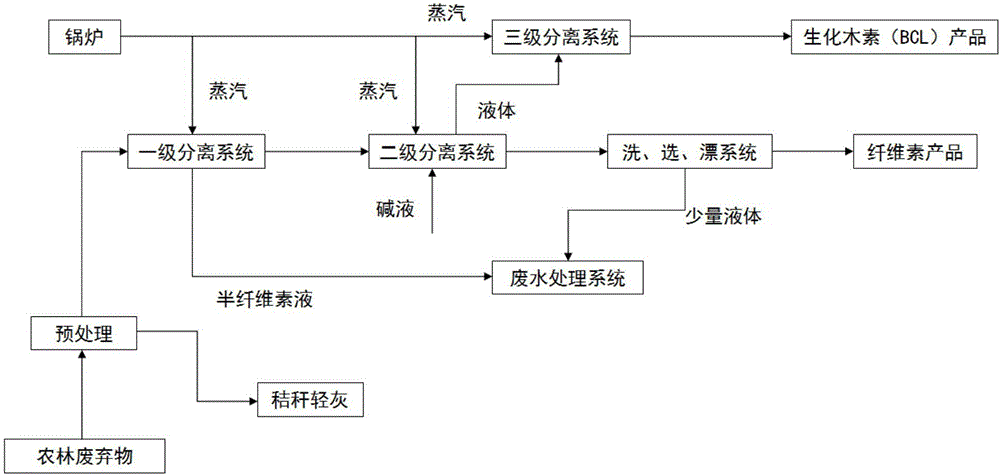

[0055] (1) After the agricultural and forestry waste (crop straw) is pretreated, cut and dedusted, it enters the separation section, where hemicellulose, cellulose and lignin are separated by physical and chemical methods, and straw light ash is produced. The separated Hemicellulose is in the liquid phase, that is, hemicellulose liquid.

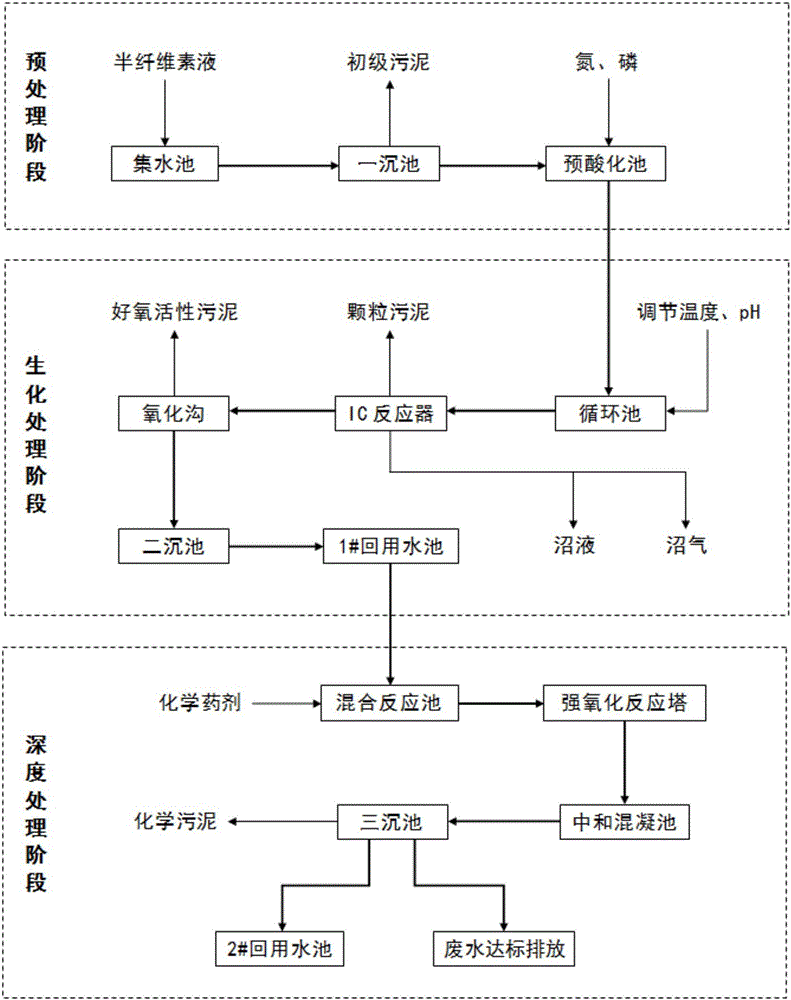

[0056] (2) The hemicellulose liquid enters the wastewater treatment system, and after the pretreatment stage, the suspended solids are removed to produce primary sludge, and the biochemical treatment stage removes a large amount of soluble COD (chemical oxygen demand) to produce remaining activated sludge and biogas slurry, and the advanced treatment stage Removing a small amount of pollutants that are not easily biodegradable produces chemical sludge.

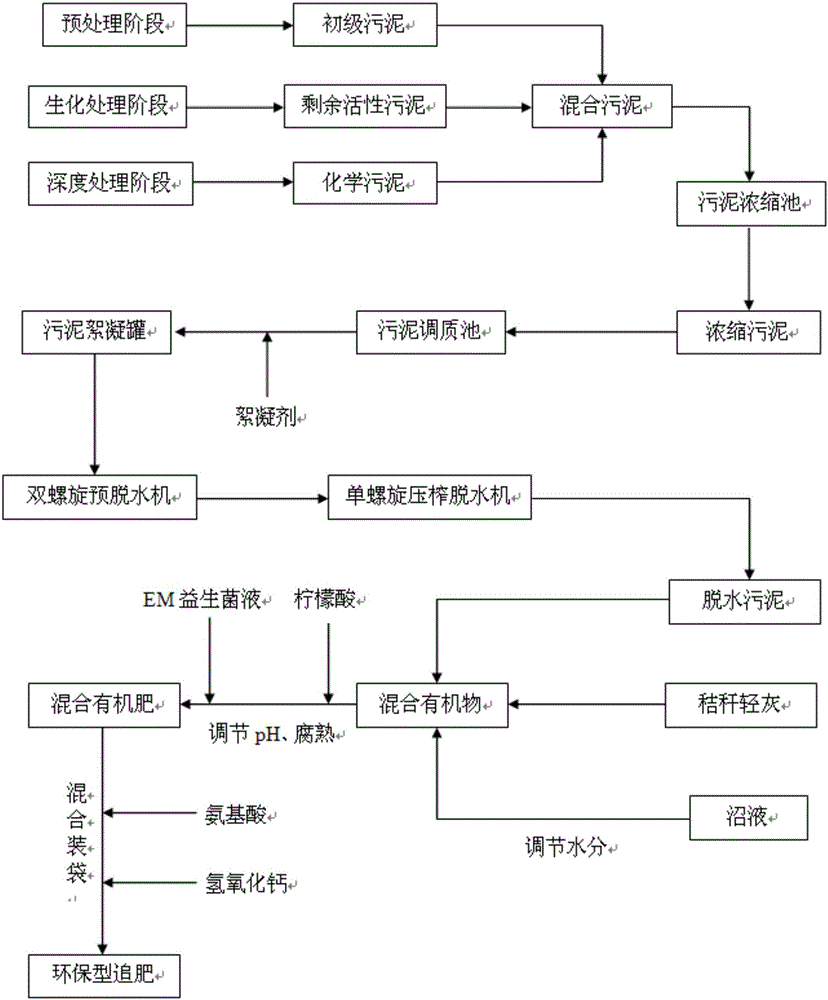

[0057] (3) The primary sludge, remaining activated sludge and chemical sludge enter the sludge thickening tank and mix evenly to obtain mixed sludge, and then use the principle of gravity sed...

Embodiment 2

[0065] (1) After the agricultural and forestry waste (crop straw) is pretreated, cut and dedusted, it enters the separation section, where hemicellulose, cellulose and lignin are separated by physical and chemical methods, and straw light ash is produced. The separated Hemicellulose is in the liquid phase, that is, hemicellulose liquid.

[0066] (2) The hemicellulose liquid enters the wastewater treatment system, and after the pretreatment stage, the suspended solids are removed to produce primary sludge, and the biochemical treatment stage removes a large amount of soluble COD (chemical oxygen demand) to produce remaining activated sludge and biogas slurry, and the advanced treatment stage Removing a small amount of pollutants that are not easily biodegradable produces chemical sludge.

[0067] (3) The primary sludge, remaining activated sludge and chemical sludge enter the sludge thickening tank and mix evenly to obtain mixed sludge, and then use the principle of gravity sed...

Embodiment 3

[0075] (1) After the agricultural and forestry waste (crop straw) is pretreated, cut and dedusted, it enters the separation section, where hemicellulose, cellulose and lignin are separated by physical and chemical methods, and straw light ash is produced. The separated Hemicellulose is in the liquid phase, that is, hemicellulose liquid.

[0076] (2) The hemicellulose liquid enters the wastewater treatment system, and after the pretreatment stage, the suspended solids are removed to produce primary sludge, and the biochemical treatment stage removes a large amount of soluble COD (chemical oxygen demand) to produce remaining activated sludge and biogas slurry, and the advanced treatment stage Removing a small amount of pollutants that are not easily biodegradable produces chemical sludge.

[0077] (3) The primary sludge, remaining activated sludge and chemical sludge enter the sludge thickening tank and mix evenly to obtain mixed sludge, and then use the principle of gravity sed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com