Surface molecularly imprinted composite material and its preparation method and application

A technology of surface molecular imprinting and composite materials, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the problems of small adsorption capacity, low removal efficiency, adsorption performance and selectivity of target pollutants impact and other issues, to achieve the effect of reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

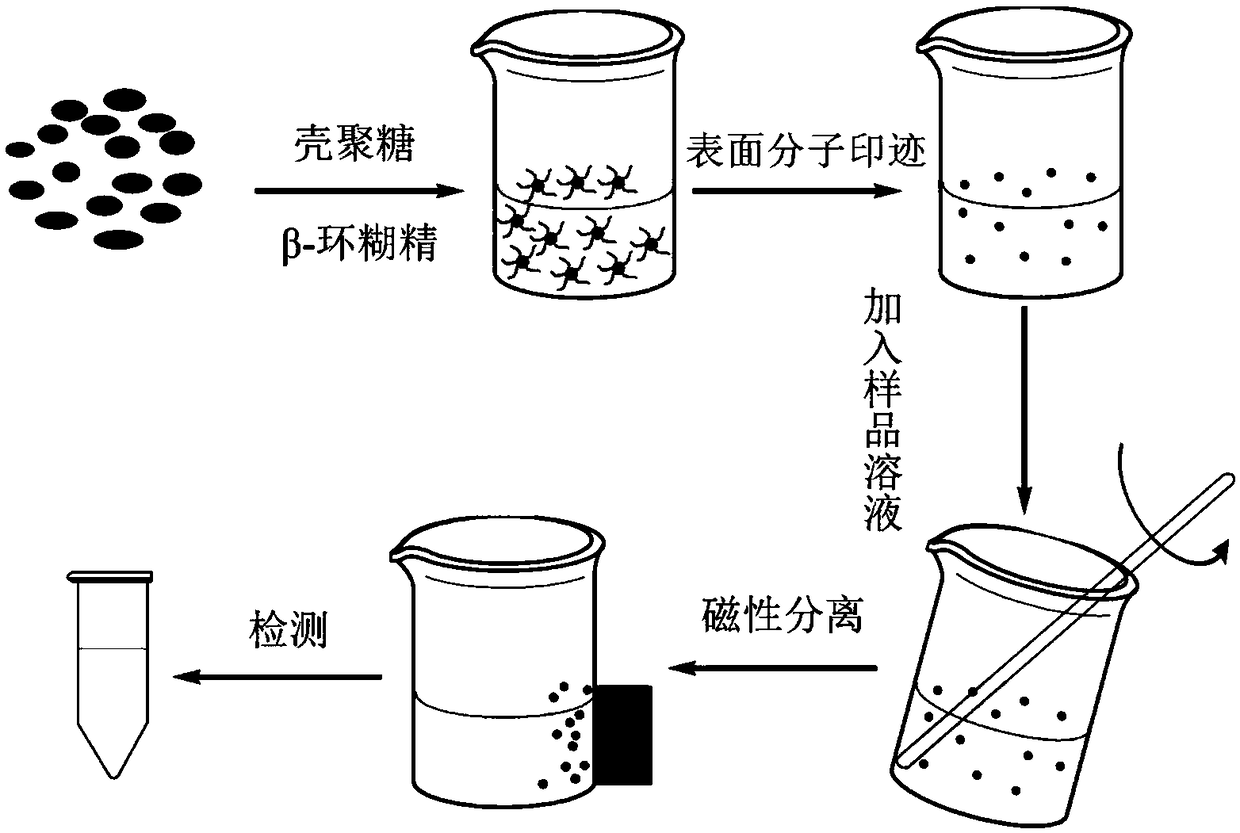

[0052] A method for preparing the surface molecularly imprinted composite material of the present invention, the preparation process is as follows figure 1 shown, including the following steps:

[0053] (1) Preparation of magnetic nano-ferric oxide: take 1.72g FeCl 2 4H 2 O and 4.72 g FeCl 3 ·6H 2 O was dissolved in 80 mL of degassed ultrapure water under N 2 Stir vigorously at a speed of 800 rpm under protection, raise the temperature to 80°C, add 10 mL of ammonia water dropwise, and reflux the reaction for 30 min. Separate the black product with a Nd–Fe–B permanent magnet, and pour out the supernatant at the same time. The precipitate (black product) was washed with ultrapure water to remove unreacted reagents, and dried in vacuum to obtain magnetic nano-ferric oxide.

[0054] (2) Preparation of maleamide-based β-CD: Take 6g β-cyclodextrin (β-CD) and 13.0g maleic anhydride in 100mL dimethylformamide (DMF), in N 2 Stir fully under protection until it is completely disso...

Embodiment 2

[0067] An application of the surface molecularly imprinted composite material of the present invention in removing bisphenol A in water comprises the following steps:

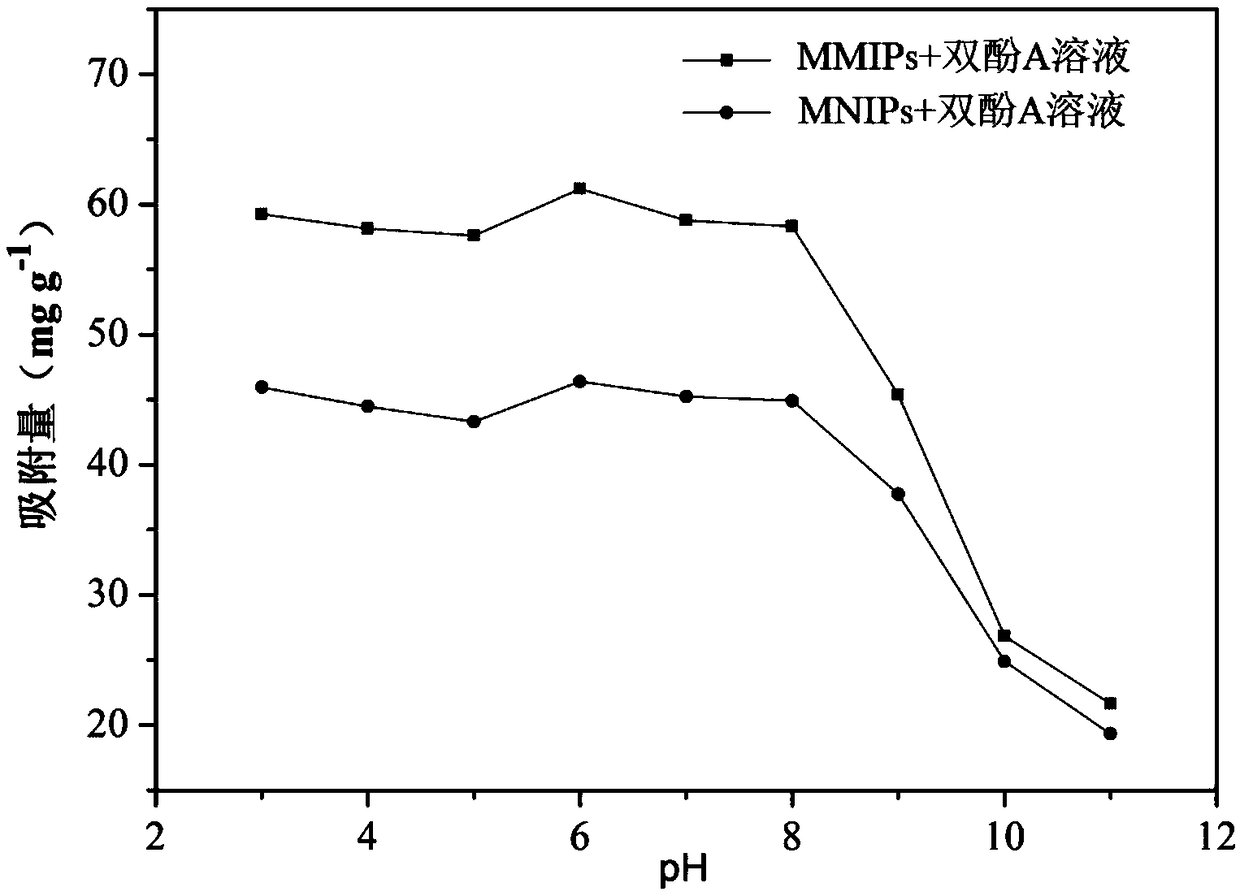

[0068] Experimental group (MMIPs): 0.02 g of MMIPs in Example 1 was placed in 50 mL of bisphenol A solution with an initial concentration of 200 mg / L, wherein the ionic strength of the bisphenol A solution was 15 mM in terms of NaCl concentration. The pH value of the solution was adjusted to 3, 4, 5, 6, 7, 8, 9, 10, 11 with a concentration of 1M HCl solution or a concentration of 1M NaOH solution. At 25°C and 180rpm, shake at constant temperature for 24h. The treated solution is separated from solid and liquid under the action of an external magnetic field, and the supernatant is filtered through a filter with a pore size of 0.22 μm to obtain a filtrate. The residual concentration of bisphenol A in the filtrate was measured with an ultraviolet-visible spectrophotometer at a wavelength of 278 nm, and the adsorp...

Embodiment 3

[0075] An application of the surface molecularly imprinted composite material of the present invention in removing bisphenol A in water comprises the following steps:

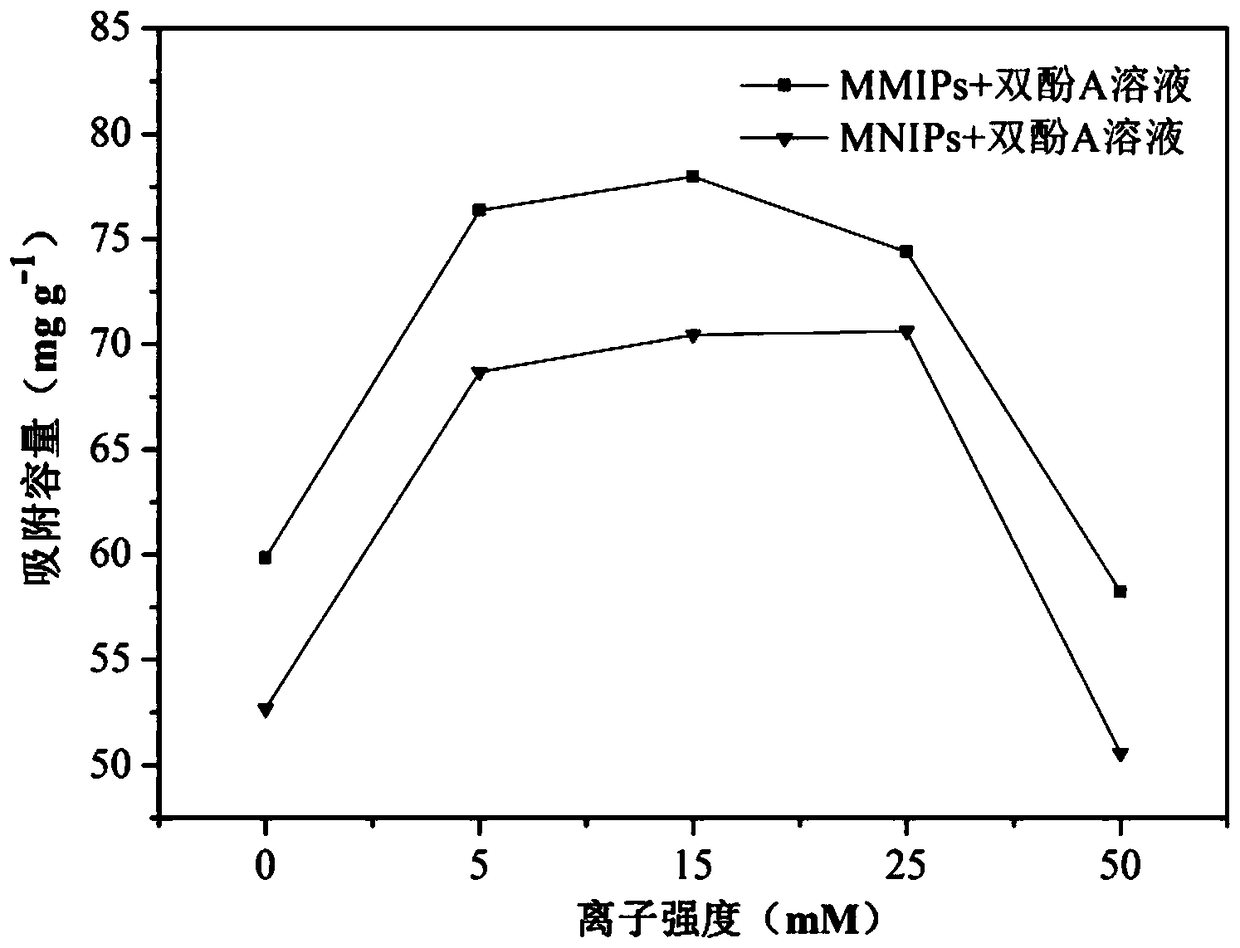

[0076] Experimental group (MMIPs): take 0.02g of MMIPs in Example 1 and put them in 50mL of bisphenol A solutions with ionic strength (NaCl) of 0, 5mM, 15mM, 25mM, and 50mM respectively, wherein the initial concentration of bisphenol A solution is 200mg / L. The pH of the solution was adjusted to 6 with a 1M HCl solution or a 1M NaOH solution. Shake at 25°C and 180rpm for 40min at constant temperature. The treated solution is separated from solid and liquid under the action of an external magnetic field, and the supernatant is filtered through a filter with a pore size of 0.22 μm to obtain a filtrate, thereby completing the treatment of bisphenol A.

[0077] Control group (MNIPs): take 0.02g of MNIPs in the comparative example and put them in 50mL of bisphenol A solution with ionic strength (NaCl) of 0, 5mM, 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com