Nitrogen-doped three-dimensional bicontinuous porous structure ultrathin carbon layer and preparation method and application thereof

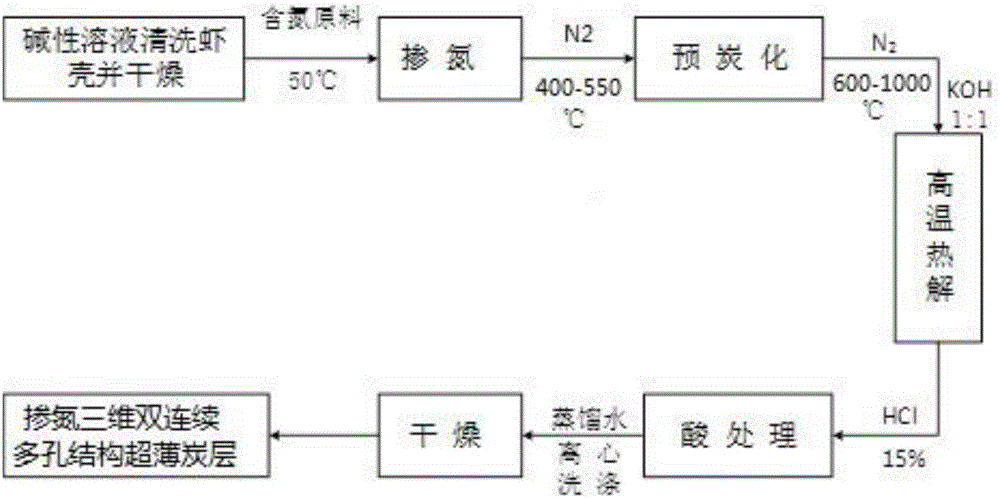

A porous structure, double continuous technology, applied in the field of biomass carbon material preparation and application, can solve the problems of high cost and complicated process, and achieve the effect of low cost, simple process and high nitrogen doping amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Fresh shrimp shells were ultrasonically cleaned with deionized water for 3 times, then ultrasonically immersed in 10% NaOH solution for 1 h, poured off the solution, and dried in an air drying oven at 80°C for 12 h. Take 8g of dried shrimp shells and 40g of urea (mass ratio of shrimp shells and urea is 1:5) into a beaker, add 100ml of deionized water, stir magnetically to completely dissolve the urea, and heat at 50°C until the water evaporates completely. Then grind it into powder in a mortar and put it into a crucible, under the protection of nitrogen (flow rate 100mL / min), raise the temperature to 400°C at a rate of 10°C / min in a tube furnace, and keep it for 1h for pre-carbonization get the precursor. Grind and mix the low-temperature pyrolyzed substance and potassium hydroxide at a mass ratio of 1:1, put them in a crucible, place them in a tube furnace, and heat them at 10°C / min under the protection of nitrogen (flow rate: 100mL / min). The temperature was raised to...

Embodiment 2

[0050] Fresh shrimp shells were ultrasonically cleaned with deionized water for 3 times, then ultrasonically immersed in a 10% NaOH solution for 1 h, poured off the liquid, and dried in an air drying oven at 80°C for 12 h. Take 15g of dried shrimp shells, 0.15g of melamine (mass ratio of shrimp shells to melamine: 1:0.01), add 80ml of deionized water, stir magnetically to completely dissolve the melamine, and heat at 50°C until the water evaporates completely. Then grind it into a powder in a mortar, put it into a crucible, crush it, put it into a crucible, and heat it up to 450°C at a rate of 10°C / min in a tube furnace under the protection of argon (flow rate: 100mL / min). And keep it for 1h, and perform pre-carbonization to obtain a precursor. Grind and mix the low-temperature pyrolyzed substance and sodium hydroxide at a mass ratio of 1:1, put them in a crucible, place them in a tube furnace, and heat them at 10°C / min under the protection of argon (flow rate: 100mL / min). Th...

Embodiment 3

[0052] Fresh shrimp shells were ultrasonically cleaned with deionized water for 3 times, then ultrasonically immersed in 10% KOH solution for 2 h, poured off the solution, and dried in an air drying oven at 80°C for 12 h. Take dried shrimp shells and pyrrole at a mass ratio of 1:5, put them in a beaker, add 100ml of deionized water, stir magnetically to completely dissolve the pyrrole, and heat at 50°C until the water evaporates completely. Then grind it into powder in a mortar and put it into a crucible, under the protection of nitrogen (flow rate 200mL / min), raise the temperature to 500°C at a rate of 10°C / min in a tube furnace, and keep it for 1h for pre-carbonization get the precursor. Grind and mix the low-temperature pyrolyzed substance and potassium carbonate at a mass ratio of 1:3, put them in a crucible, and place them in a tube furnace at a rate of 10°C / min under the protection of nitrogen (flow rate: 200mL / min). Raise the temperature to 850°C and keep it for 1h, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com