Method for recycling selenium from tellurium deposition waste liquid

A technology for recovering selenium and waste liquid, applied in the direction of element selenium/tellurium, etc., can solve the problems of selenium dispersion, influence on the purification of tellurium dioxide, and inability to concentrate recovery, and achieve the effect of simple operation, low processing cost and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

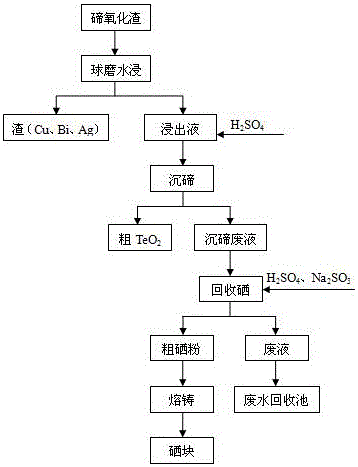

[0029] refer to figure 1 , present embodiment a kind of method that reclaims selenium from heavy tellurium waste liquid, this method comprises the following steps:

[0030] (1) Ball mill 500g of oxide slag containing tellurium selenium and add 1500g of water to obtain leachate;

[0031] (2) adding sulfuric acid to the leaching solution to obtain tellurium dioxide precipitation and tellurium sinking waste liquid;

[0032] (3) Add sulfuric acid to the tellurium sinking waste liquid in step (2) to adjust H + The concentration is 0.1mol / L, and the solution contains 1.5 g / L of selenium;

[0033] (4) Add 7.2 g of sodium sulfite to the tellurium sinking waste liquid in step (3), heat up to 80° C., stir for 1.5 hours and then filter to obtain crude selenium;

[0034] (5) Wash the crude selenium with water and dry it to remove the attached sulfate radical;

[0035] (6) Combine the selenium-precipitated liquid separated in step (4) with the washing water in step (5) and send it to t...

Embodiment 2

[0039] refer to figure 1 , a kind of method that reclaims selenium from heavy tellurium waste liquid of embodiment 2, compared with embodiment 1, there is following difference:

[0040] (1) Add 3 kg of water to 1 kg of oxide slag containing tellurium and selenium by ball milling to obtain leachate;

[0041] (2) adding sulfuric acid to the leaching solution to obtain tellurium dioxide precipitation and tellurium sinking waste liquid;

[0042] (3) Add sulfuric acid to the tellurium sinking waste liquid in step (2) to adjust H + The concentration is 0.2mol / L, and the solution contains 2.0g / L selenium;

[0043] (4) Add 9.6 g of sodium sulfite to the tellurium sinking waste liquid in step (3), heat up to 85° C., stir for 2 hours and then filter to obtain crude selenium;

[0044] Using a method for recovering selenium from tellurium-precipitating waste liquid according to this embodiment, the selenium content in the treated waste liquid is 0.06 g / L.

Embodiment 3

[0046] refer to figure 1 , a kind of method that reclaims selenium from heavy tellurium waste liquid of embodiment 3, compared with embodiment 1, there is following difference:

[0047] (1) Ball mill 500g of oxide slag containing tellurium selenium and add 1500g of water to obtain leachate;

[0048] (2) adding sulfuric acid to the leaching solution to obtain tellurium dioxide precipitation and tellurium sinking waste liquid;

[0049] (3) Add sulfuric acid to the tellurium sinking waste liquid in step (2) to adjust H + The concentration is 0.2mol / L, and the solution contains 1.8g / L selenium;

[0050] (4) Add 8.6 g of sodium sulfite to the tellurium sinking waste liquid in step (3), heat up to 90° C., stir for 2.5 hours and then filter to obtain crude selenium;

[0051] Using a method for recovering selenium from tellurium-precipitating waste liquid according to this embodiment, the selenium content in the treated waste liquid is 0.05 g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com