Three-dimensionally ordered macroporous-mesoporous graphene, preparation method and application thereof

A mesoporous graphene, three-dimensional ordering technology, applied in graphene, nano-carbon, etc., can solve the problems of cumbersome process, difficult control, large randomness of sample shape, etc., and achieve simple process, strong controllability and low cost. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Polymer spheres can be purchased commercially or can be prepared in-house. In one example, the preparation method of organic polymer template spheres of orderly stacking includes: polymerizing organic monomers in a solvent under the action of an initiator to form polymer polymer spheres; The molecular spheres are separated by orderly packing (such as suction filtration, centrifugation, or natural sedimentation). The particle size of the polymer polymer spheres can be regulated by controlling the reaction conditions, and the specific control method can adopt known techniques in the art.

[0037] The ordered stacked organic polymer template spheres were immersed in a suitable precursor solution. The precursor can be properly selected according to the ceramic to be prepared. In the present invention, as a three-dimensional porous ceramic substrate, oxide ceramics can be used, including various oxides such as metal oxides and silicon oxides, and combinations thereof, wher...

Embodiment 1

[0064] Polymethyl methacrylate (PMMA) was prepared by using methyl methacrylate and hydroxybenzoic acid as raw materials and potassium persulfate as an initiator. in N 2 Protect the atmosphere, mix methyl methacrylate and hydroxybenzoic acid in distilled water, keep stirring, and heat to 70°C in a water bath. After being incubated for 15 minutes, potassium persulfate initiator was added, and after another 40 minutes of incubation, the reaction was terminated; the obtained solution was centrifuged and dried to obtain orderly arranged PMMA templates. The selected centrifugal speed was 2000 rpm, and the drying temperature was 60 ℃;

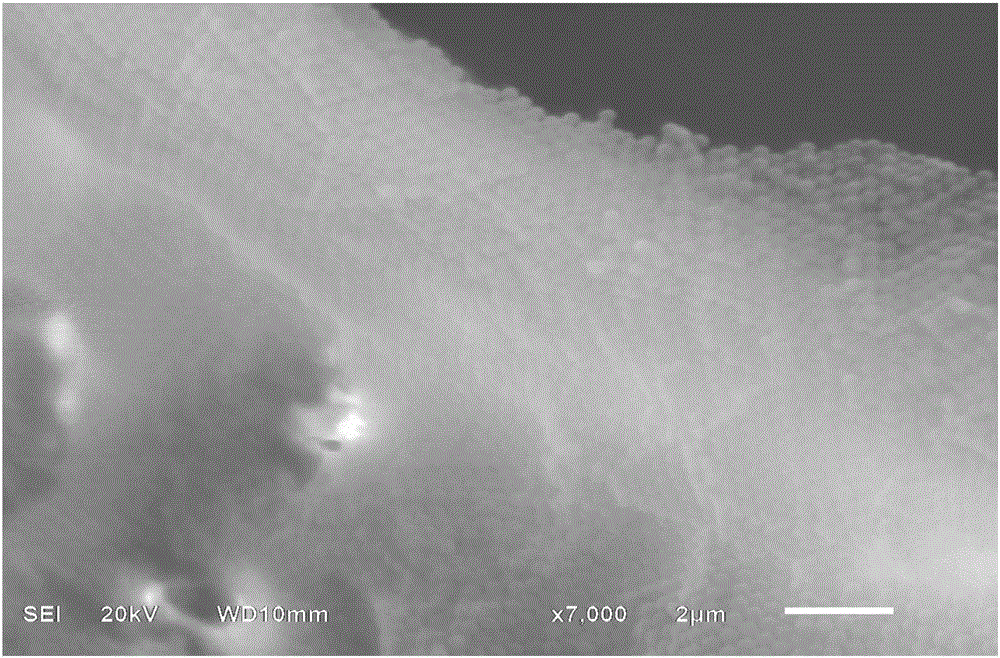

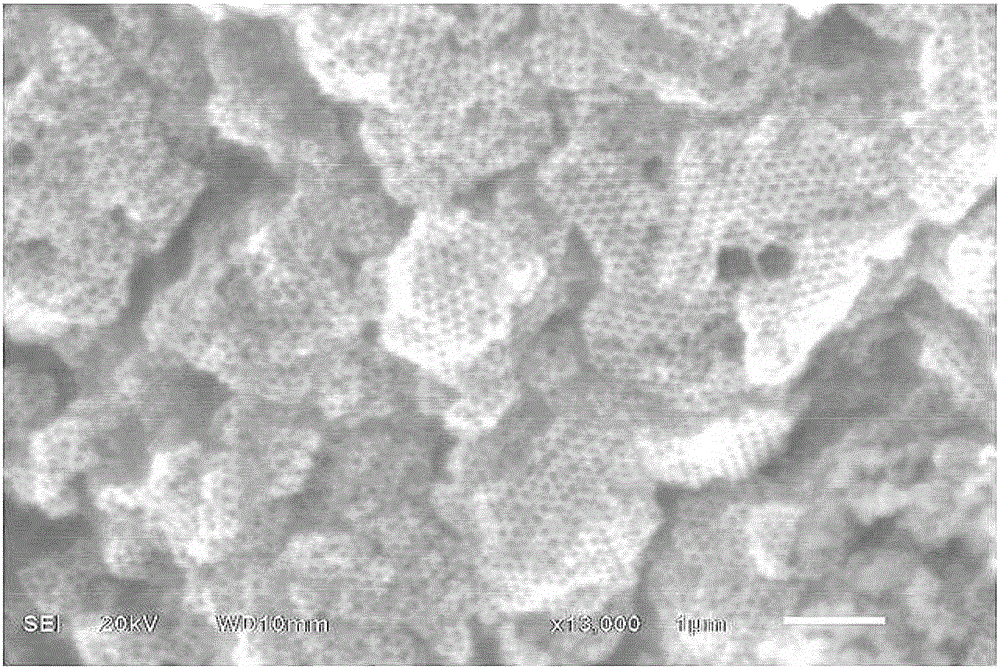

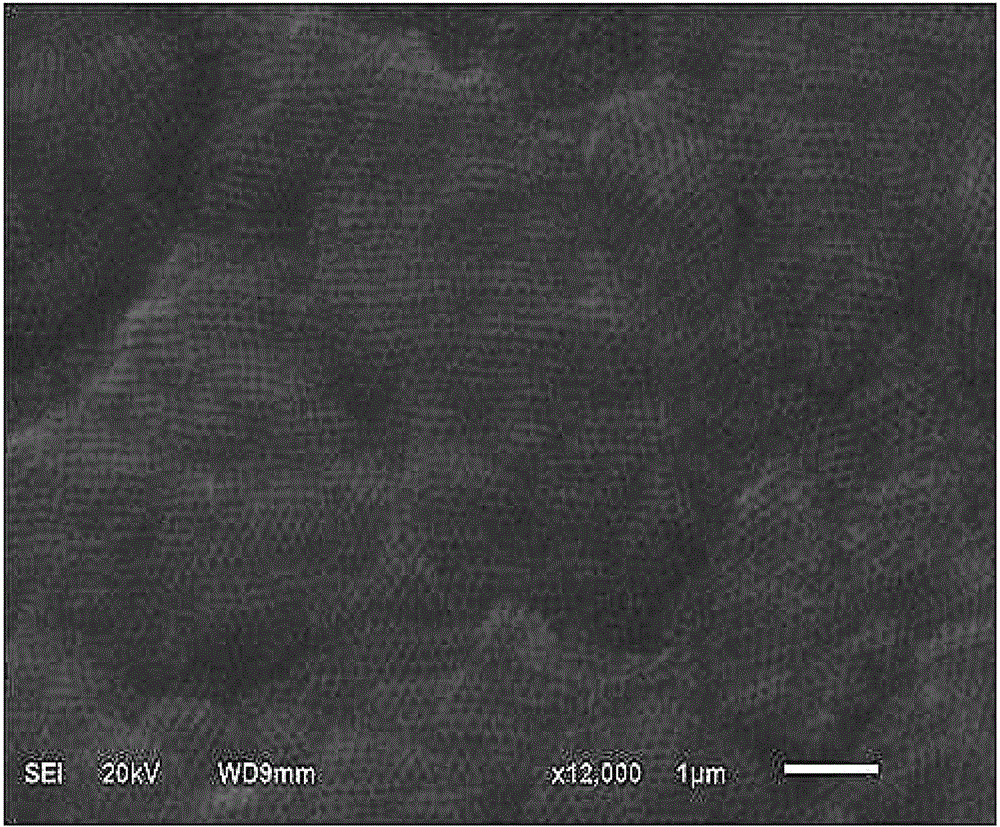

[0065] The obtained PMMA template was immersed in an aluminum nitrate precursor solution (concentration: 0.5 mol / L), and after soaking, it was separated by suction filtration and dried at room temperature for 24 hours. The dried sample was then heat-treated under an argon protective atmosphere at a temperature of 350° C. for 3 hours. Then heat-tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com